Here are the key people in the organization:

- Shri Chetan Shah - Chairman (Non-Executive)

- Shri Rajnikant Pajwani - Whole Time Director & Chief Executive Officer

- Shri Ashok Kadakia - Non-Executive Independent Director

- Shri Abhilash Munsif - Non-Executive Independent Director

- Shri Harish Motiwalla - Non-Executive Independent Director

- A team of senior executives

![27 | P a g e

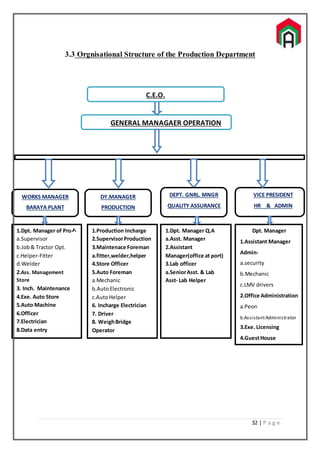

CHAPTER: 3.

DATA ANALYSIS

&

INTERPRETATION

[PRODUCTION DEPARTMENT]](https://image.slidesharecdn.com/9-hariameet-161217202548/85/Ashapura-Minechem-27-320.jpg)

![58 | P a g e

6. BIBLOGRAPHY

The sources of information and data are:-

Personally collected information and asked questions.

BOOKS

Bentonite Book [ A magazine that gives detail information about

the core products of Ashapura group]

Akanksha Book [ A magazine that binds Ashapura company’s

all level of employees]

WEBSITES

www.ashapura.com

www.moneycontrol.com

www.wikipedia.com](https://image.slidesharecdn.com/9-hariameet-161217202548/85/Ashapura-Minechem-58-320.jpg)