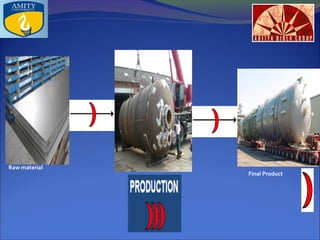

Grasim Industries Ltd. is one of India's largest companies established in 1947. It started as a textile manufacturer and has since diversified into various industries including viscose staple fiber, cement, chemicals, and textiles. The company owns manufacturing facilities in India and various countries around the world. Its core businesses are viscose staple fiber and cement which contribute over 90% of its revenues. The company has an engineering division that manufactures plant and machinery used in its viscose staple fiber production and exports these internationally. Key departments in the engineering division include project planning, fabrication, machine shop, assembly, and quality control. The document provides an overview of Grasim Industries' history and operations.