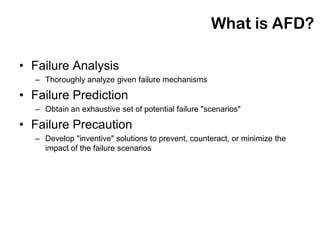

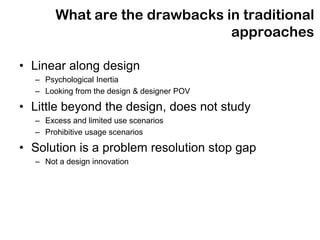

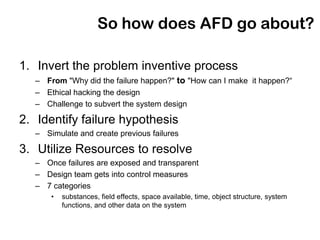

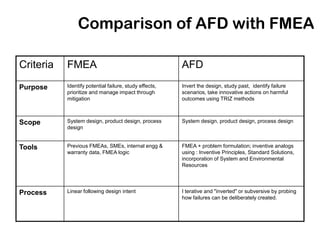

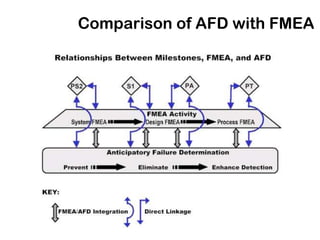

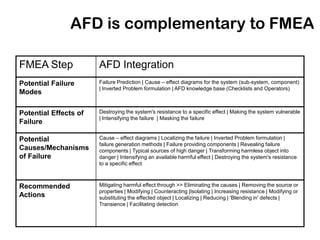

The document discusses anticipatory failure determination (AFD) as an innovative approach to preventing design failures by inverting traditional problem-solving methods and analyzing potential failures. It contrasts AFD with failure modes and effects analysis (FMEA), emphasizing AFD's focus on simulating failures and generating inventive solutions to enhance system resilience. It also outlines the advantages of using AFD, such as its iterative process and alignment with various design methodologies.

![Alternatives

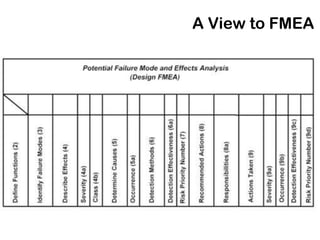

• Failure Modes & Effects Analysis [FMEA]

• Potential Problem Analysis [PPA]

• Hazards Operability Analysis [HAZOP]](https://image.slidesharecdn.com/afd-121221001506-phpapp02/85/Anticipatory-Failure-Determination-2-320.jpg)