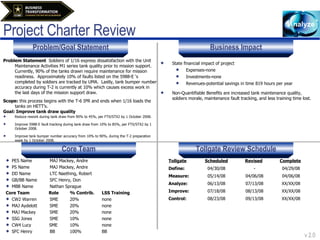

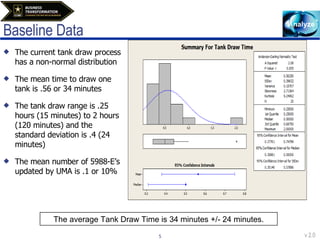

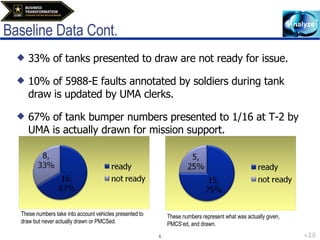

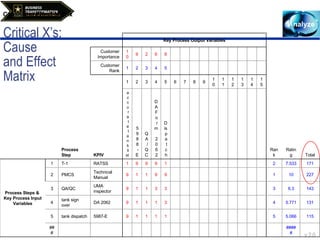

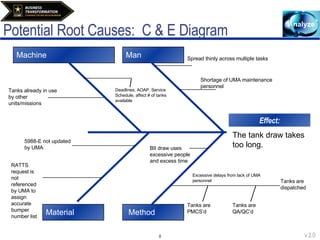

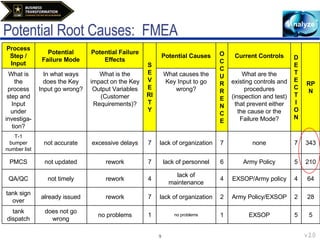

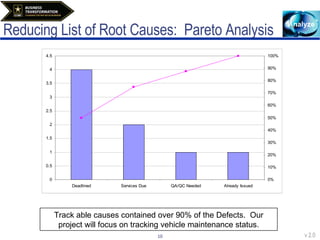

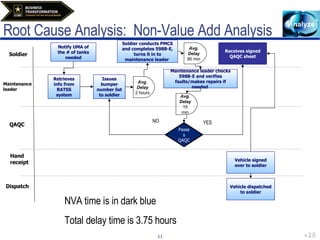

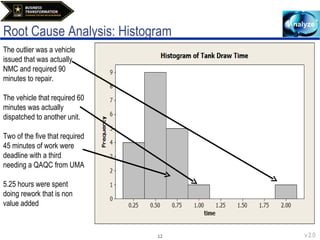

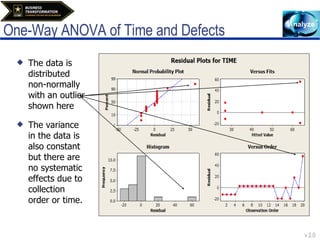

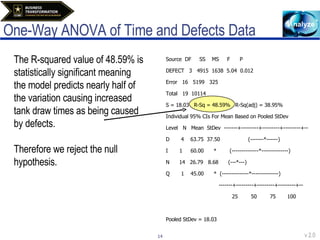

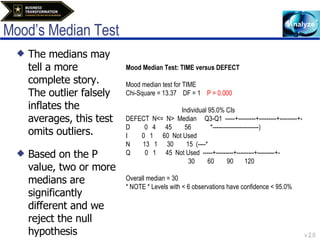

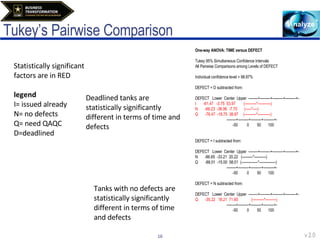

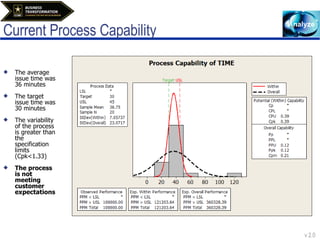

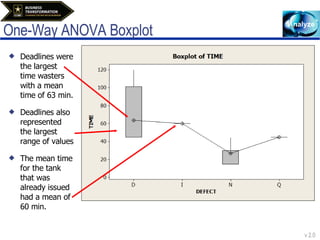

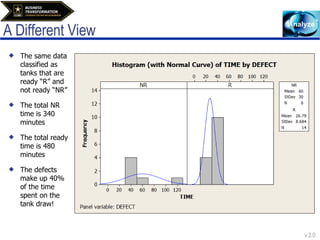

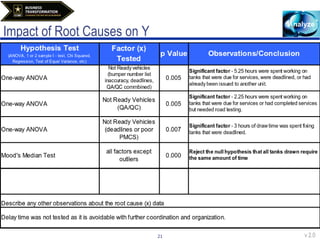

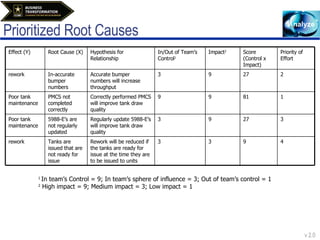

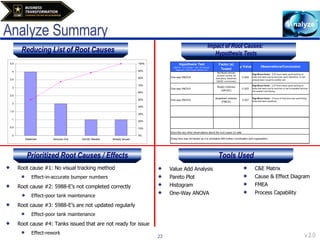

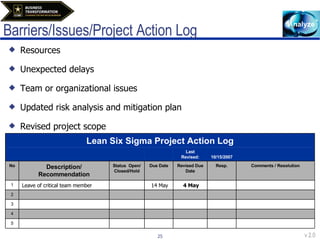

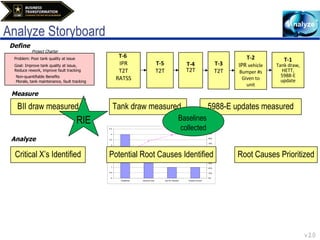

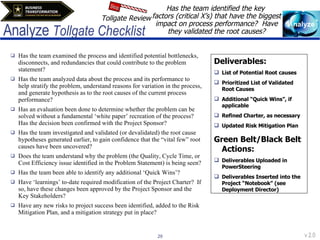

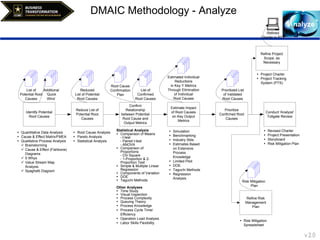

This document summarizes the Analyze phase of a Lean Six Sigma project aimed at improving the quality of tank maintenance for the 1/16 soldiers. Potential root causes for issues like poor PMCS completion, faulty 5988-E forms, and tanks being issued that are not ready were identified and prioritized. Statistical analysis found deadlined tanks and those already issued took significantly longer to process than tanks with no defects. The top root causes were inaccurate bumper number lists, incomplete PMCS, and 5988-E forms not being regularly updated.