This document discusses ammonia production including the Haber process, key steps in production, plant design software, and modeling and simulation. The main points are:

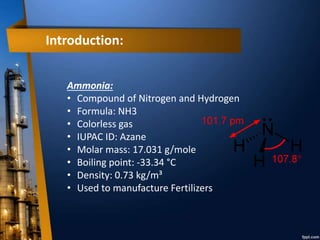

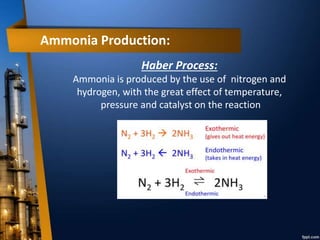

- Ammonia is produced from nitrogen and hydrogen using the Haber process under high temperature, pressure, and with a catalyst.

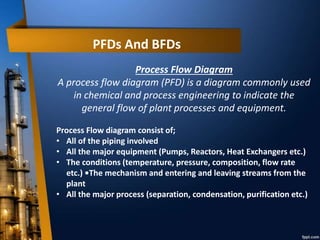

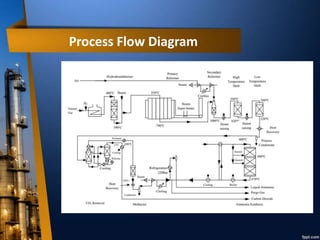

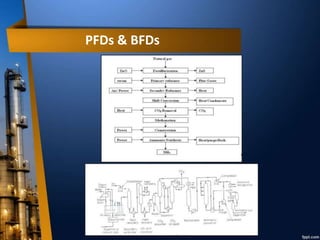

- The main steps in production are preparing PFDs and BFDs, plant designing, and modeling and simulation.

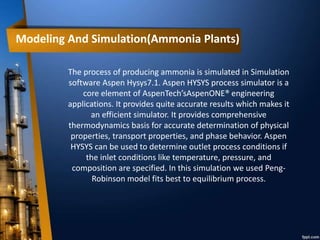

- Common software used for plant design include Smart 3D, PDMS, PDS, and AutoCAD plant-3D. Aspen HYSYS is used to accurately model and simulate ammonia production processes.