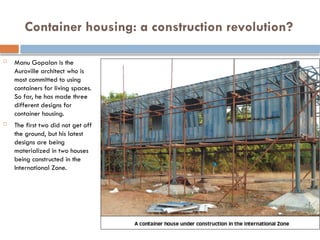

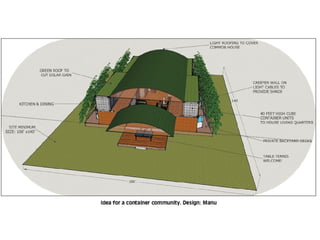

The document explores various alternative building materials such as rammed earth, papercrete, adobe, and container housing, highlighting their benefits like energy efficiency, durability, and cost-effectiveness. It emphasizes the thermal and environmental advantages of these materials while providing insights into innovative building techniques. Additionally, it discusses the potential for container houses in Auroville, which could address housing mobility and cost issues, making them an attractive option for the community.