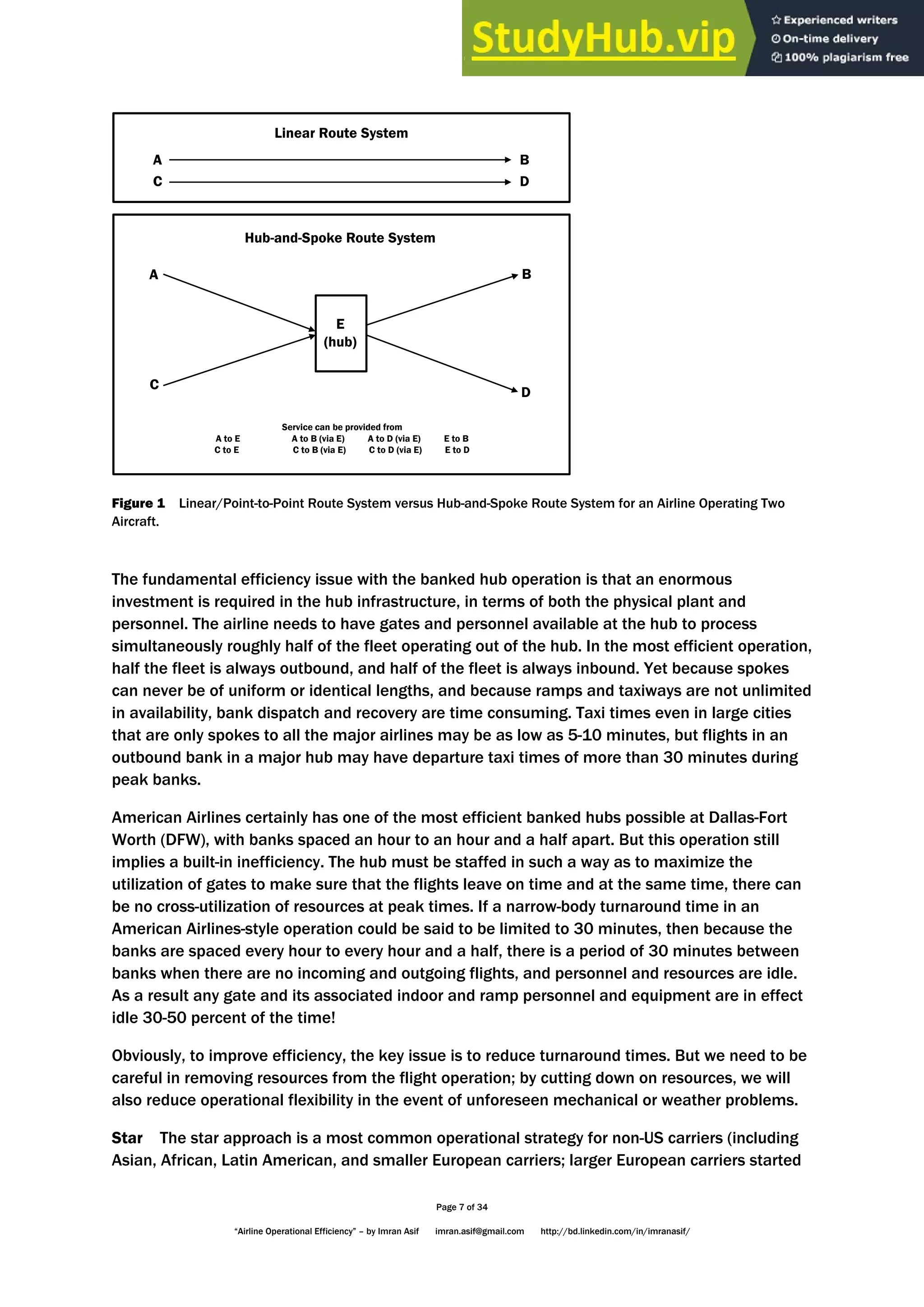

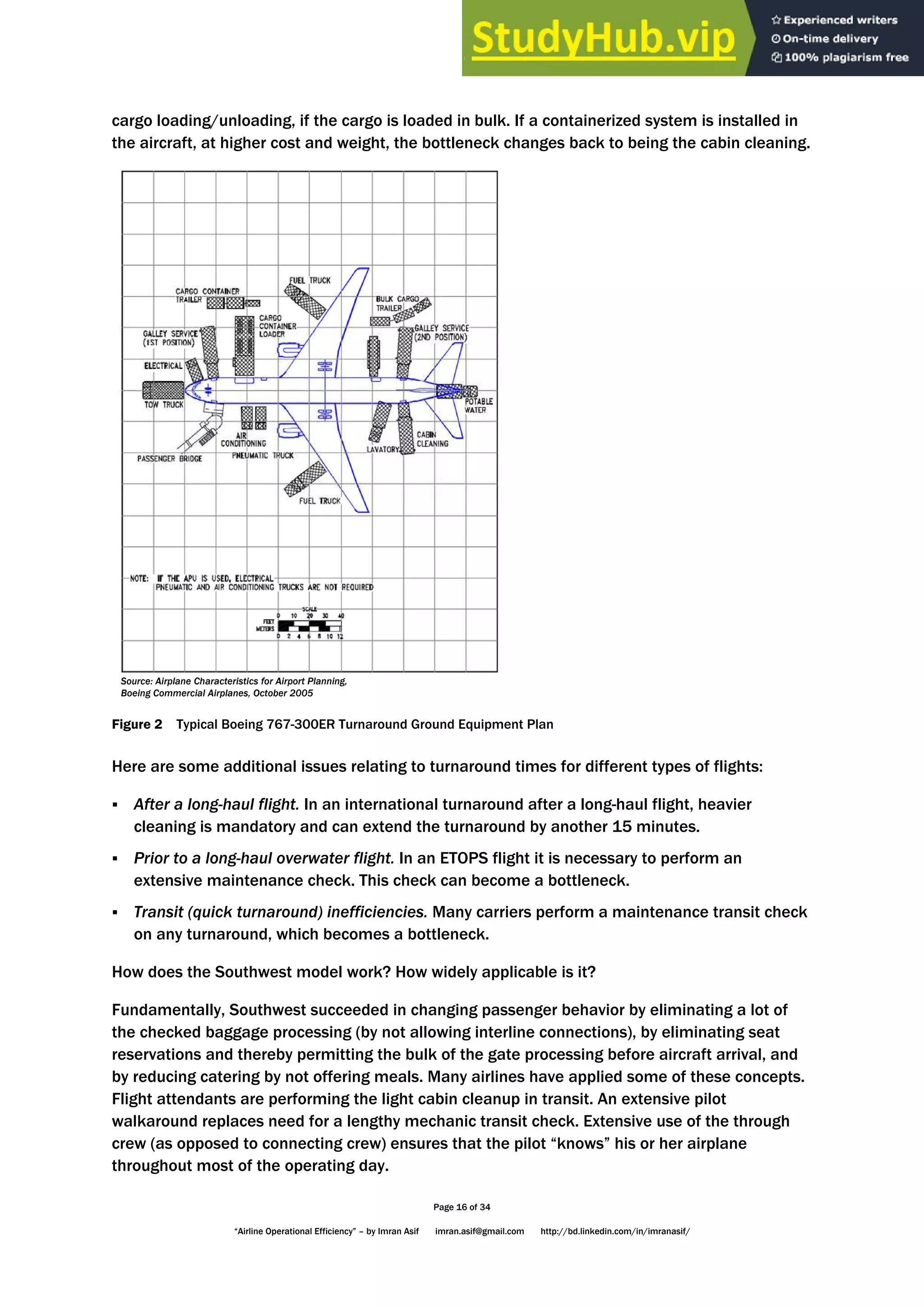

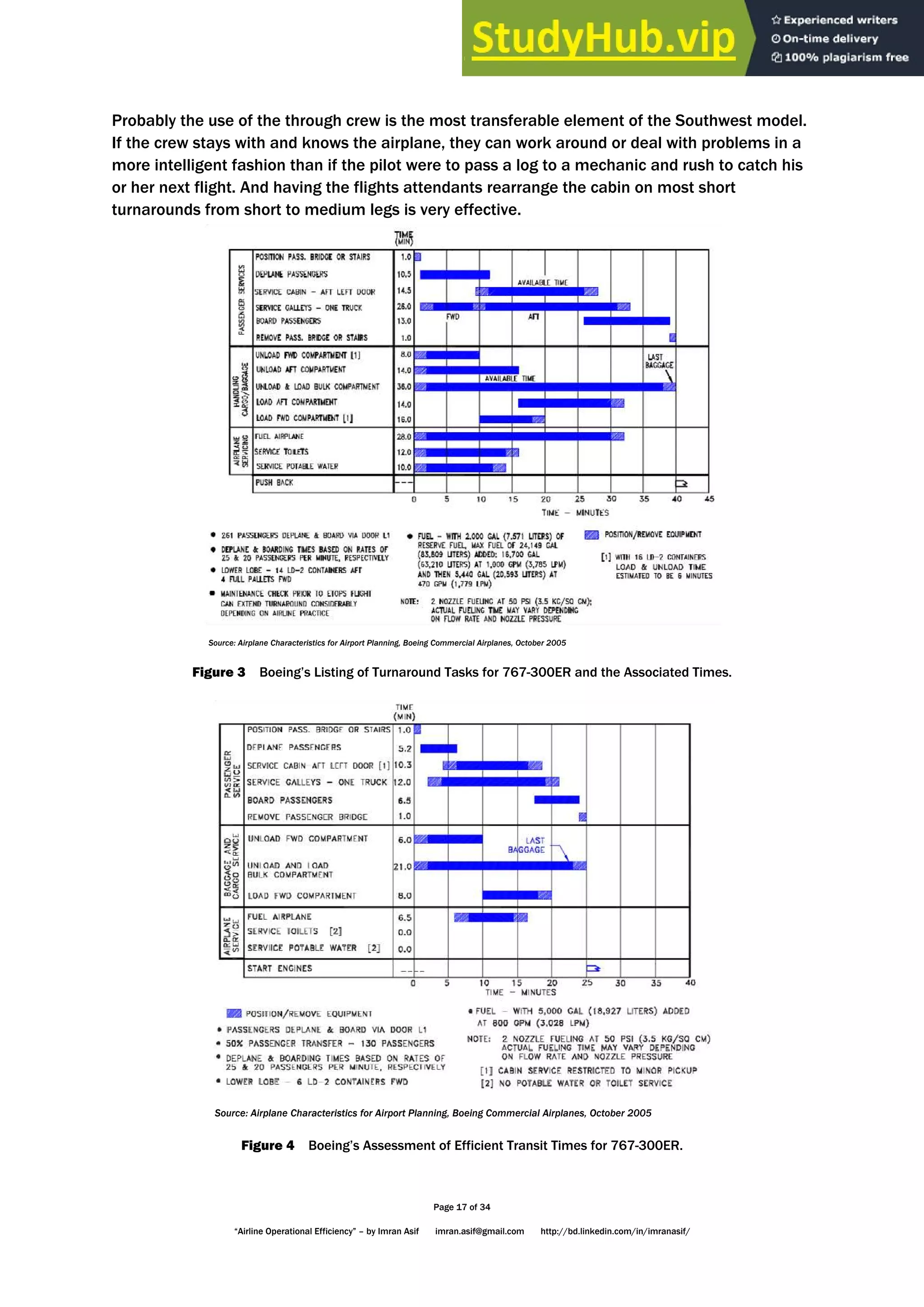

This document is a 34-page paper exploring operational efficiency within airlines. It begins by discussing how an airline's strategy, geographic area, and organizational structure can impact efficiency. It then examines various factors that influence efficiency, including turnaround times, maintenance scheduling, fleet age, and dispatch issues. The document considers different types of route structures and their relative efficiencies. It also notes potential pitfalls in how airlines analyze and interpret efficiency.