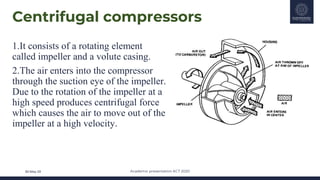

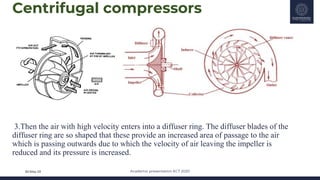

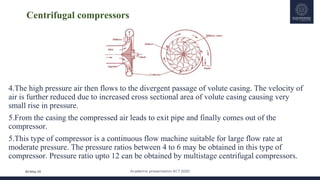

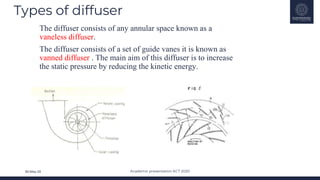

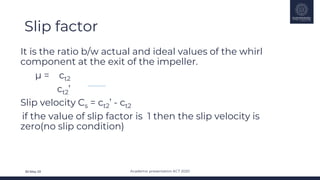

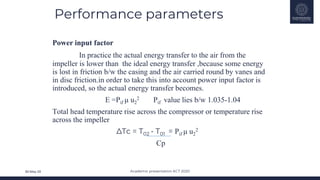

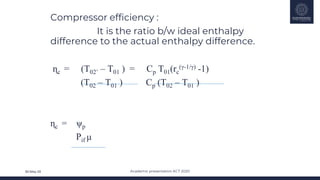

This document discusses compressors used in aircraft propulsion systems. It covers the key concepts of axial compressors including flow losses, off-design operation such as surge and stall, and performance characteristics. It also discusses centrifugal compressors, describing their basic components and operation. Different types of impeller blades and diffusers are described. The concepts of ideal energy transfer, velocity triangles, and performance parameters such as pressure coefficient and efficiency are explained.