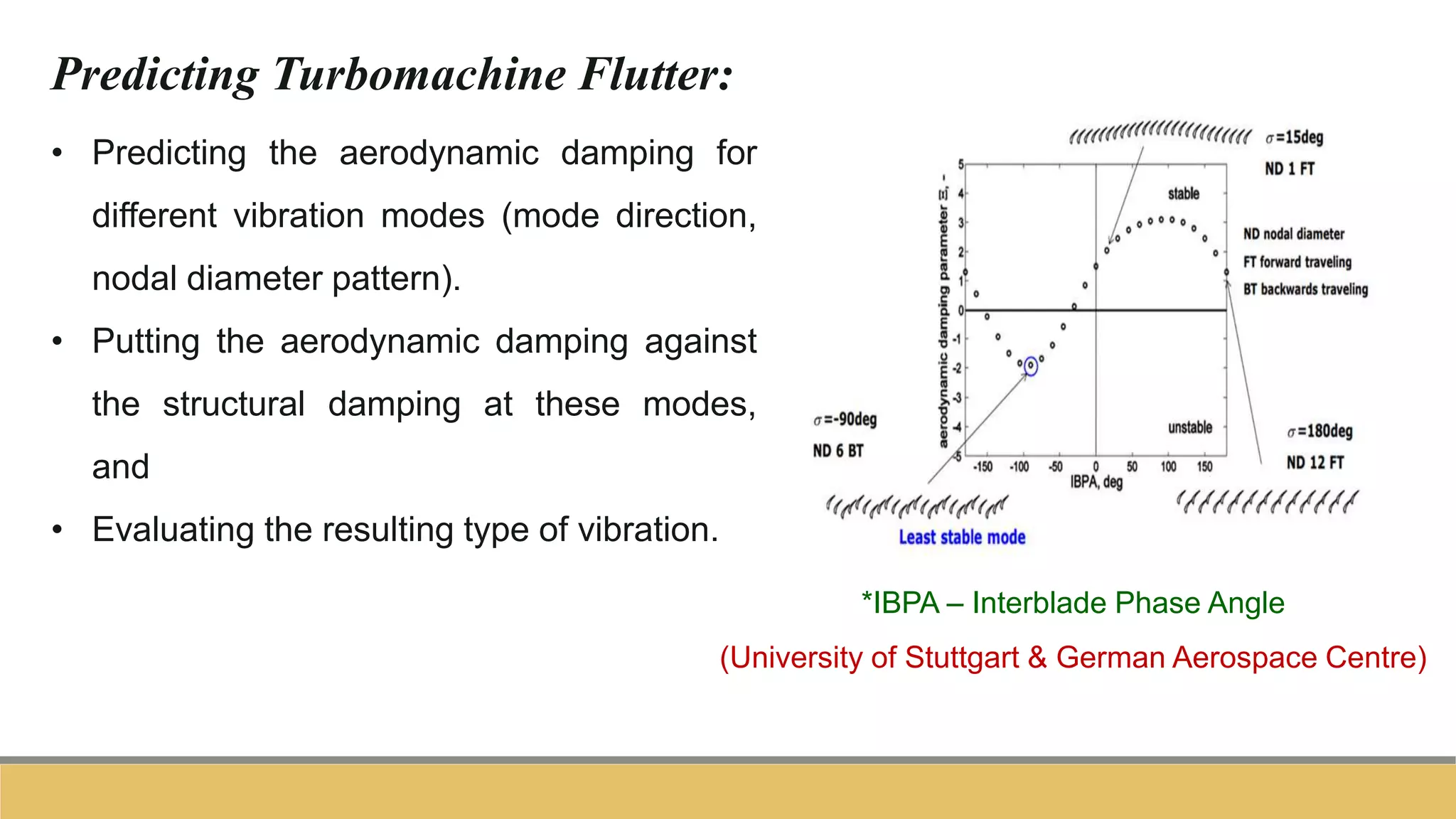

This document discusses aeroelastic flutter analysis. It begins by defining aeroelasticity and describing different aeroelastic phenomena including divergence, flutter, limit cycle oscillations, and vortex shedding. It then discusses Collar's triangle of forces and Garrick's aerothermoelastic tetrahedron models. The document defines flutter as a dangerous vibration phenomenon in structures subjected to aerodynamic forces. It provides examples of different types of flutter and describes predicting flutter in turbomachines. Finally, it summarizes a case study on material mode flutter analysis of laminated curved panels.

![Case Studies in Aeroelastic Flutter:

Case – 1:

Ganapathi and Varadan [1] performed material mode FEA analysis on laminated curved panels of

different materials to study the effect of supersonic flutter by accounting for aspect and thickness

ratios and the number of layers.

Graphs were plotted for critical dynamic pressure against an aspect ratio of 10 for orthotropic,

anisotropic & isotropic materials taking number of layers from 2 to 5 and ply angle from 0° -90°.

Results:

• The anisotropic 3 - layered panel and isotropic panel gave the best responses to the flutter due

to high directional stiffness.

• Coupling, bending, twisting etc influence the critical flutter speed and hence, flutter boundary.

• Flutter boundary is also affected by aspect ratio, irrespective of ply orientation.](https://image.slidesharecdn.com/aeroeelastics-181224105559/75/Aeroeelastic-Flutter-14-2048.jpg)