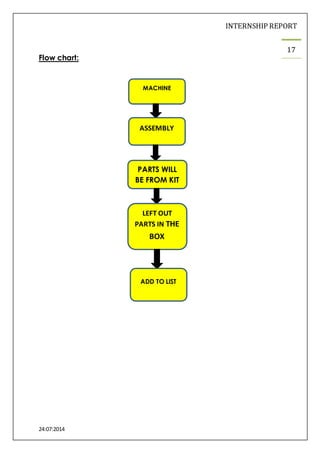

This internship report details the experiences of Mr. Aditya Velayutham during his internship at Caterpillar India Pvt Ltd, focusing on various design and manufacturing processes. It covers topics such as design for assembly (DFA), cycle time studies, and data collection methods, highlighting the importance of operational efficiency and waste reduction in manufacturing. The report also includes acknowledgments of the teamwork and support received during the internship, along with insights into Caterpillar's operations and future plans in India.