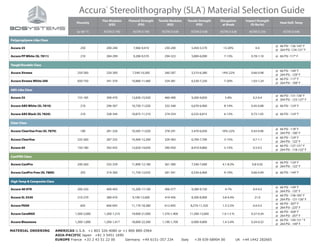

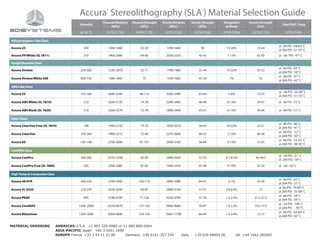

The document compares the properties and applications of various Accura stereolithography materials. It lists the materials in different classes based on their properties including polypropylene-like, tough/durable, ABS-like, clear, casting, high temperature, and composites. For each material, it provides information on their mechanical properties, color, and suitability for different applications. It also provides contact information for ordering the materials.