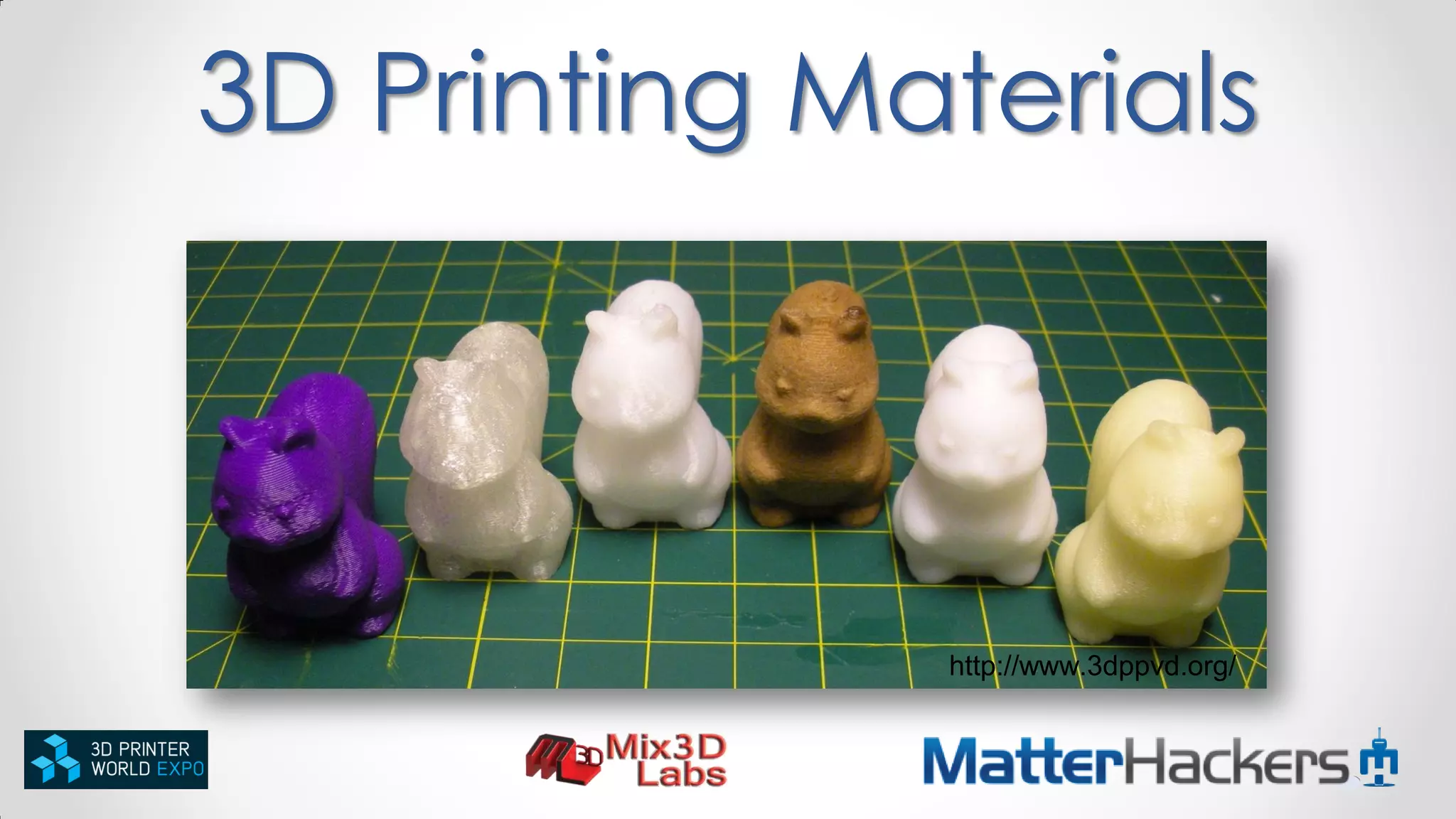

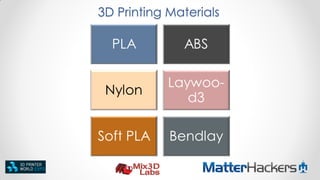

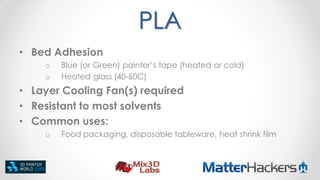

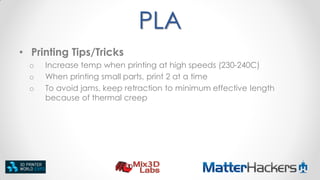

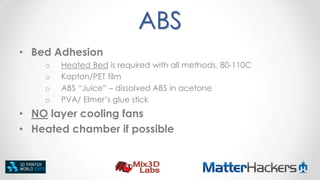

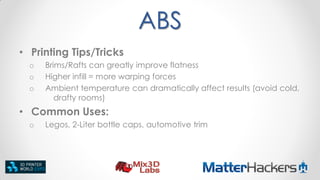

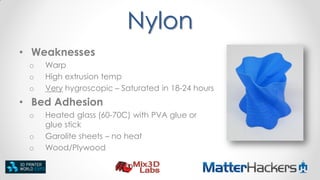

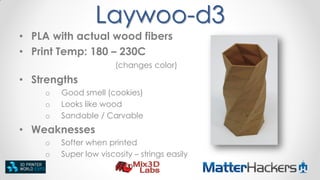

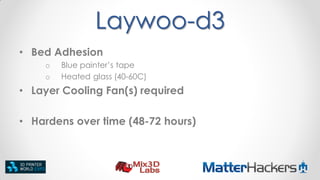

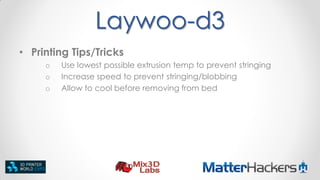

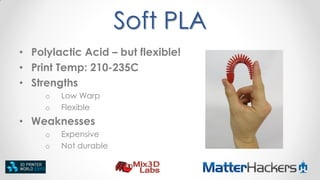

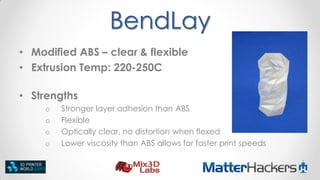

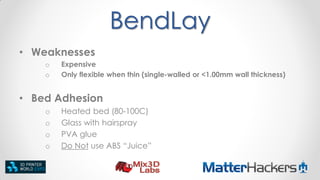

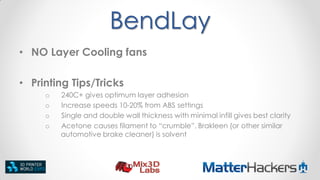

The document provides an overview of various 3D printing materials including PLA, ABS, Nylon, Laywoo-D3, Bendlay, and PETT, detailing their strengths, weaknesses, and optimal printing conditions. It emphasizes the importance of temperature, bed adhesion methods, and specific printing tips to achieve better results. Common uses for each material are also highlighted, showcasing their applications in different industries.