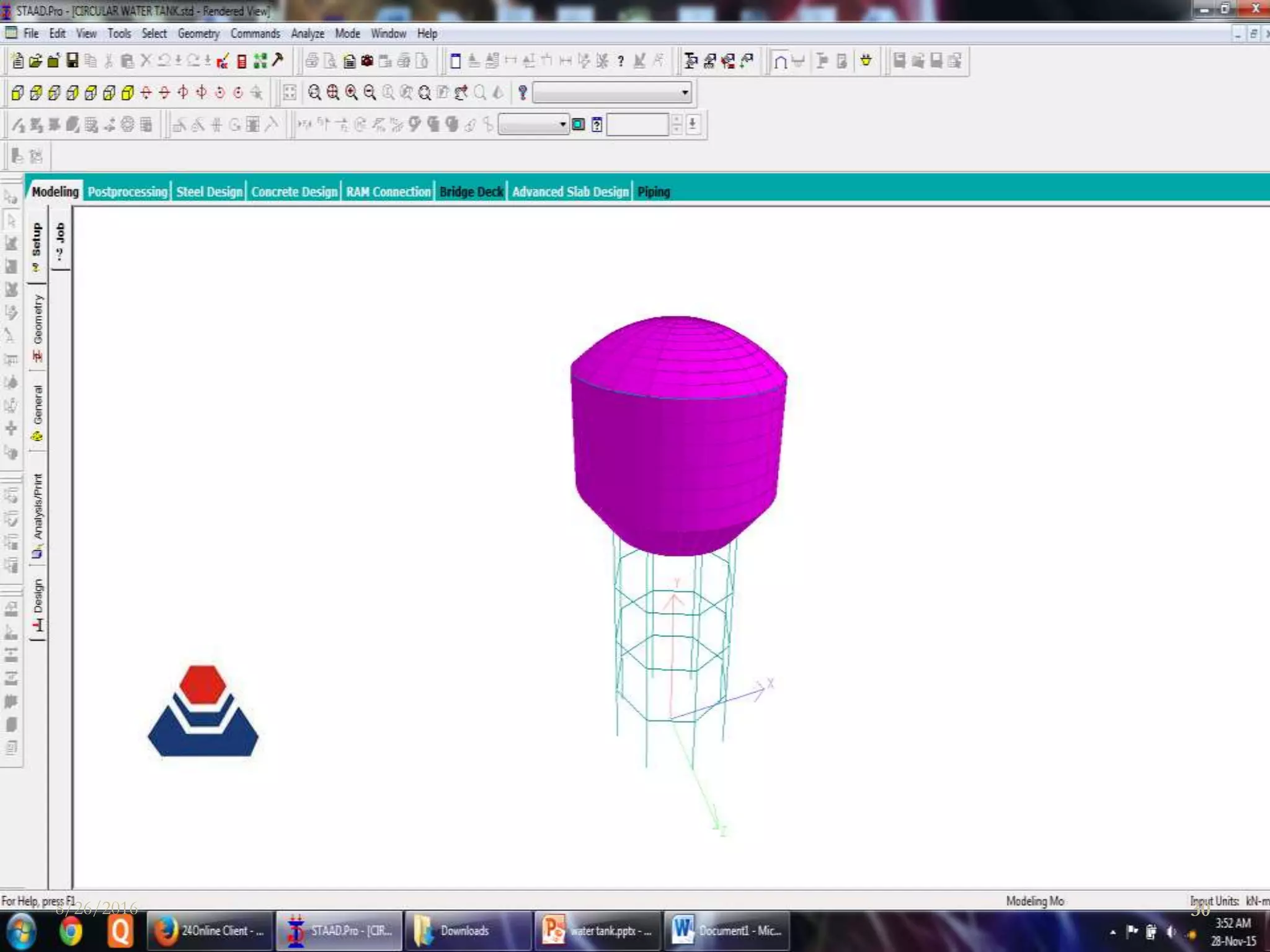

The document is a presentation on the design of an overhead water tank located at a railway colony in Allahabad, India. It includes the following key points:

- The target population is 1500 people and the maximum daily water demand calculated is 540 cubic meters.

- The proposed water tank design has a diameter of 12 meters, height of 5 meters, and volume capacity of 540 cubic meters.

- The tank will have a dome roof supported by 8 columns and be constructed of reinforced concrete designed to withstand specified loadings.

- Detailed calculations are shown for determining the dome geometry, stresses, and steel reinforcement requirements based on code specifications.

- Construction details like raft foundation, concrete grade of M

![Location: Kalyani

Target Population: 1500

Maximum daily consumption (demand)

=180% of average daily demand = 1.8q

[Ref: Water Supply Engineering by S.K.Garg, Page-19]

8/26/2016 10](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-10-2048.jpg)

![Let us assume, diameter of tank (D) = 12m (< 30m)

[as per Clause 7.2.1.1 of IS:2210-1988, page 8]

Hence, radius of tank (R) = 12/2 = 6m.

Now, volume of tank = 540 m3.

Let h be the height of the cylindrical tank.

Capacity of tank = R2 h

8/26/2016 12](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-12-2048.jpg)

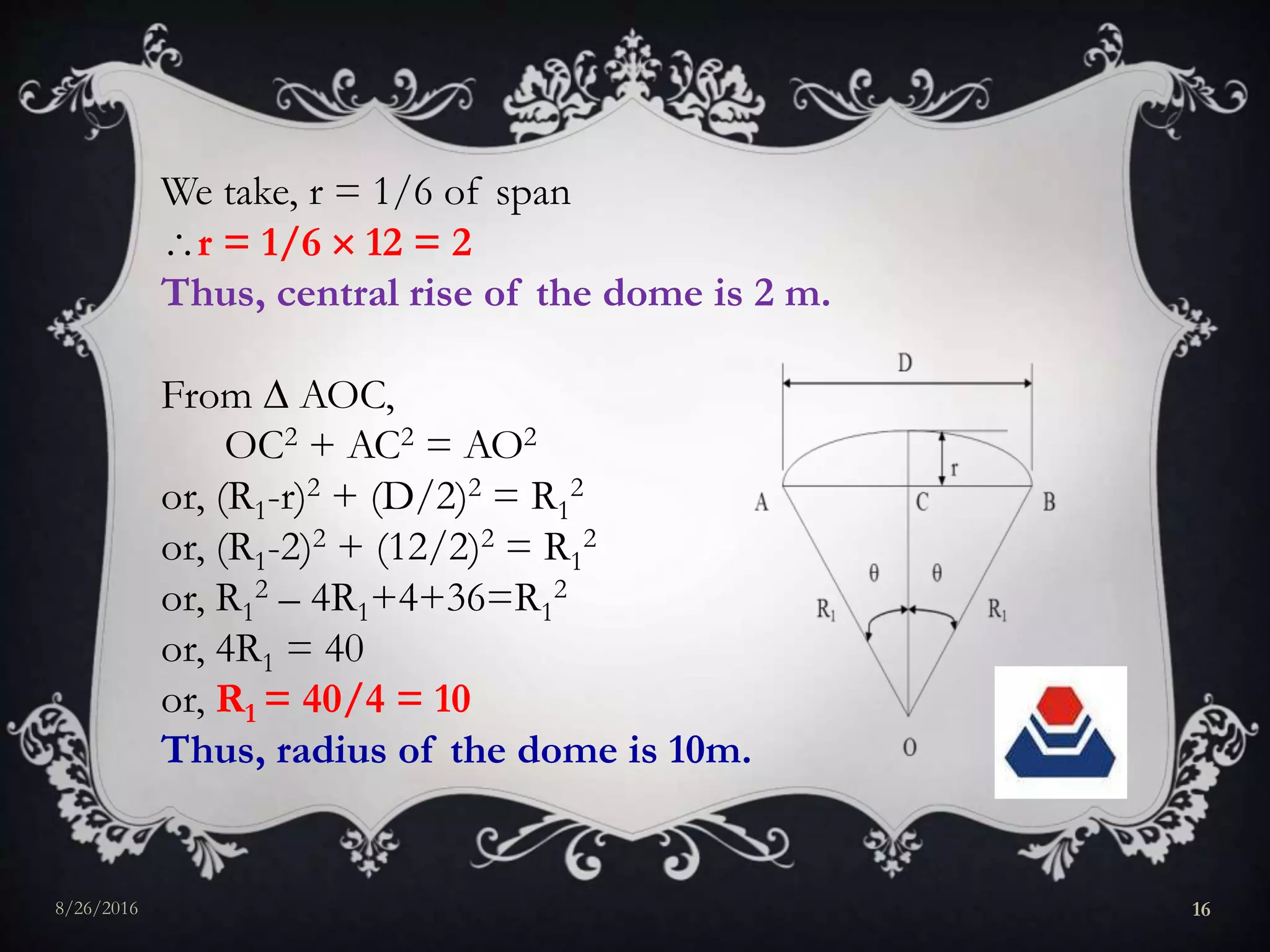

![D

r

A C B

R1 R1

O

Notations:

D = Diameter of the tank = 12m

r = Central rise of the dome

R1= Radius of the dome

= Semi-central angle of the dome

From the geometry of the figure,

AOC & BOC are right-angled triangles.

Central rise, r = 1/8 to 1/6 of span

[Ref: Advanced Reinforced Concrete by H.J.Shah, page-406]

8/26/2016 15](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-15-2048.jpg)

![Again, cos = = = = 0.8

or, = cos-1(0.8)

or, = 36.87

Thus, semi-central angle of the dome is 36.87

30<< 40. Hence, OK.

[as per IS:2210-1988, page-8]

8/26/2016 17](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-17-2048.jpg)

![Again, = 36.87< 51.8

Hence, tensile stress is not developed.

[Ref: Advanced Reinforced Concrete by H.J Shah,

page 64]

Now, r/D = 2/12 = 1/6 (< 1/5)

[as per IS: 2210-1988, page-10]

So, it is a deep doubly curved shell and membrane

analysis is required.

8/26/2016 18](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-18-2048.jpg)

![Load calculation:

We assume, thickness of top dome = 100 mm ( 40 mm)

[as per Clause 7.1.1 of IS:2210-1988, page-8]

Minimum imposed load for accessible roof = 1.5KN/m2

[as per IS-875 Part-2]

Self-weight of the dome = 0.1 25 = 2.5 KN/m2

Finishing = 0.05 24 = 1.2 KN/m2

___________________________________________________

Total load = (1.5+2.5+1.2) = 5.2 KN/m2

8/26/2016 19](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-19-2048.jpg)

![Calculation of Meridional stress and Hoop stress:

Meridional force:

Due to UDL =

[Ref: Advanced Reinforced Concrete by H.J Shah, page-64]

Meridional force = 5.2 10

= 28.89 KN.

Meridional stress for per meter span =

= 0.2889 N/mm2

0.29 N/mm2 (compressive)

8/26/2016 20](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-20-2048.jpg)

![As the minimum grade of concrete is M30, thus for M30

[as per IS-456:2000, Table-21, page-81]

σcc = 8N/mm2

Thus, 0.29 < 8 N/mm2. Hence, OK.

8/26/2016 21](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-21-2048.jpg)

![Hoop force:

Due to UDL =

[Ref: Advanced Reinforced Concrete by H.J Shah,

page-64]

Hoop force = 5.2 10

= 12.71KN.

Hoop stress for per meter span =

= 0.1271 N/mm2

0.13 N/mm2 (compressive)

Thus, 0.13 < 8 N/mm2. Hence OK.

Hence, the stresses are within the safe limit.

8/26/2016 22](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-22-2048.jpg)

![Since the stresses are very small, we provide nominal

tensile reinforcement of 0.3%

[as per IS: 3370 (Part-2:2009) page-3, Table-3 the

nominal percentage of nominal tensile reinforcement

shall not be less than 0.15% in any case]

= 0.3

or, Ast = 1000 100

or, Ast = 300 mm2

Thus, area of steel reinforcement is 300 mm2.

8/26/2016 23](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-23-2048.jpg)

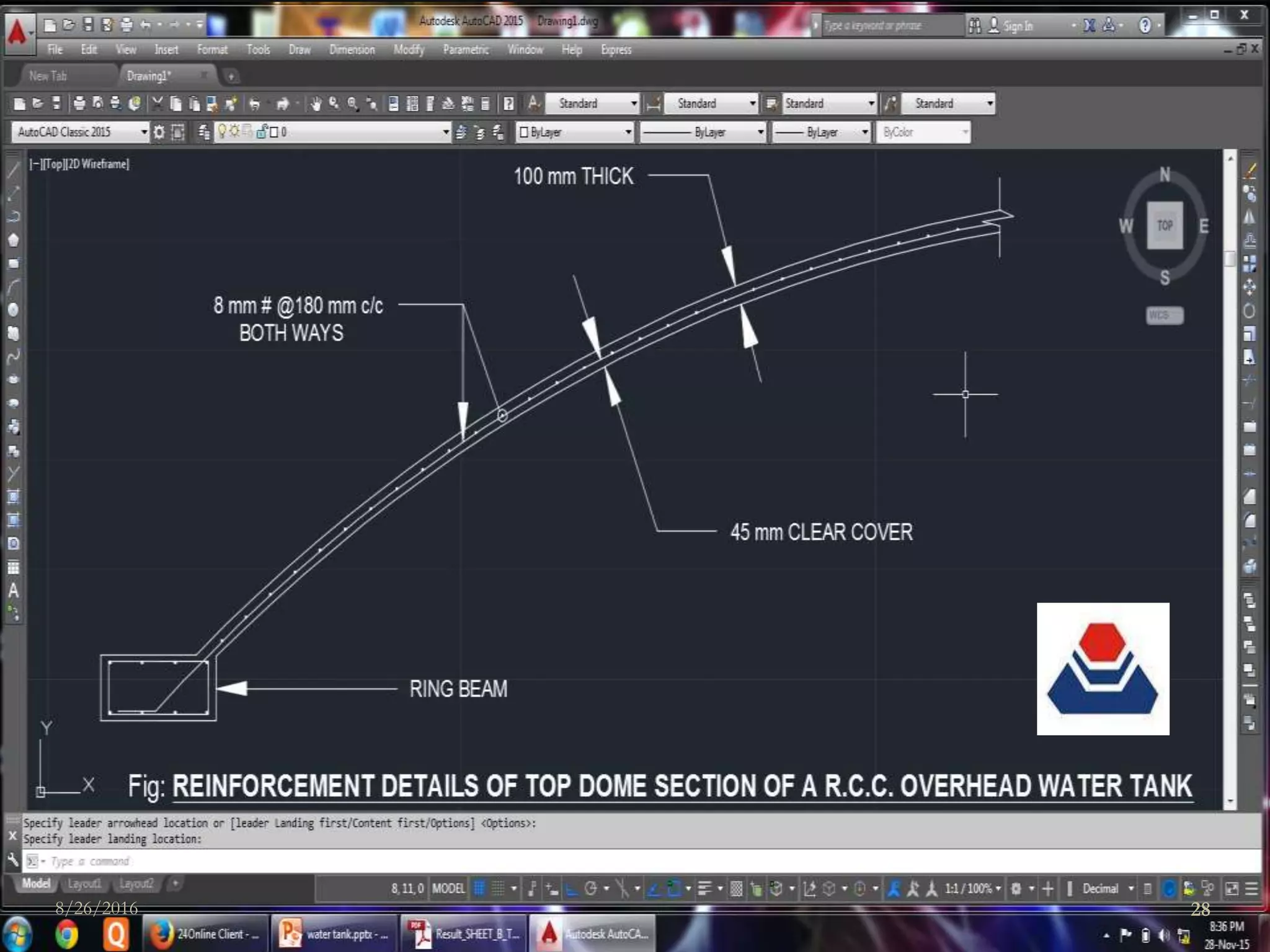

![We provide 6 - 8mm # bars,

[as per clause 12.3.1 of IS: 2210-1988]

Spacing of 8mm # bars = = 167.53 mm

180 mm c/c

Thus, we provide 6 – 8mm @180mm c/c both ways.

Actual Percentage of steel required (Pt)

= = = 0.30%

8/26/2016 24](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-24-2048.jpg)

![Clear cover [as per clause 7.1.1.1 of IS: 2210-1988]:-

(i) 15mm.

(ii) Nominal size

whichever is greater.

Now, for severe exposure, nominal cover = 45 mm

[as per Table 16 of IS: 456-2000]

As, 45 > 15mm, so we provide clear cover = 45mm.

8/26/2016 25](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-25-2048.jpg)

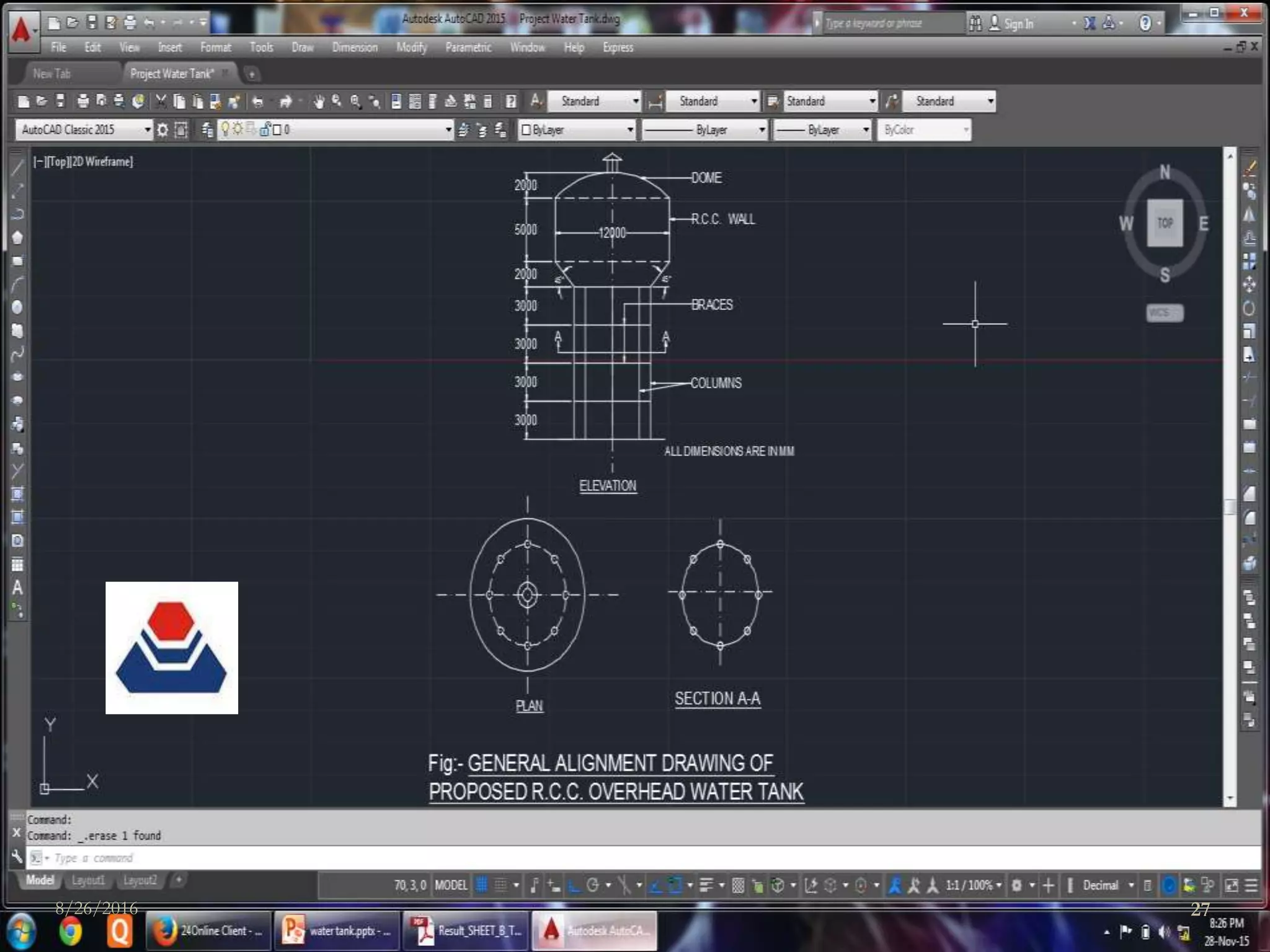

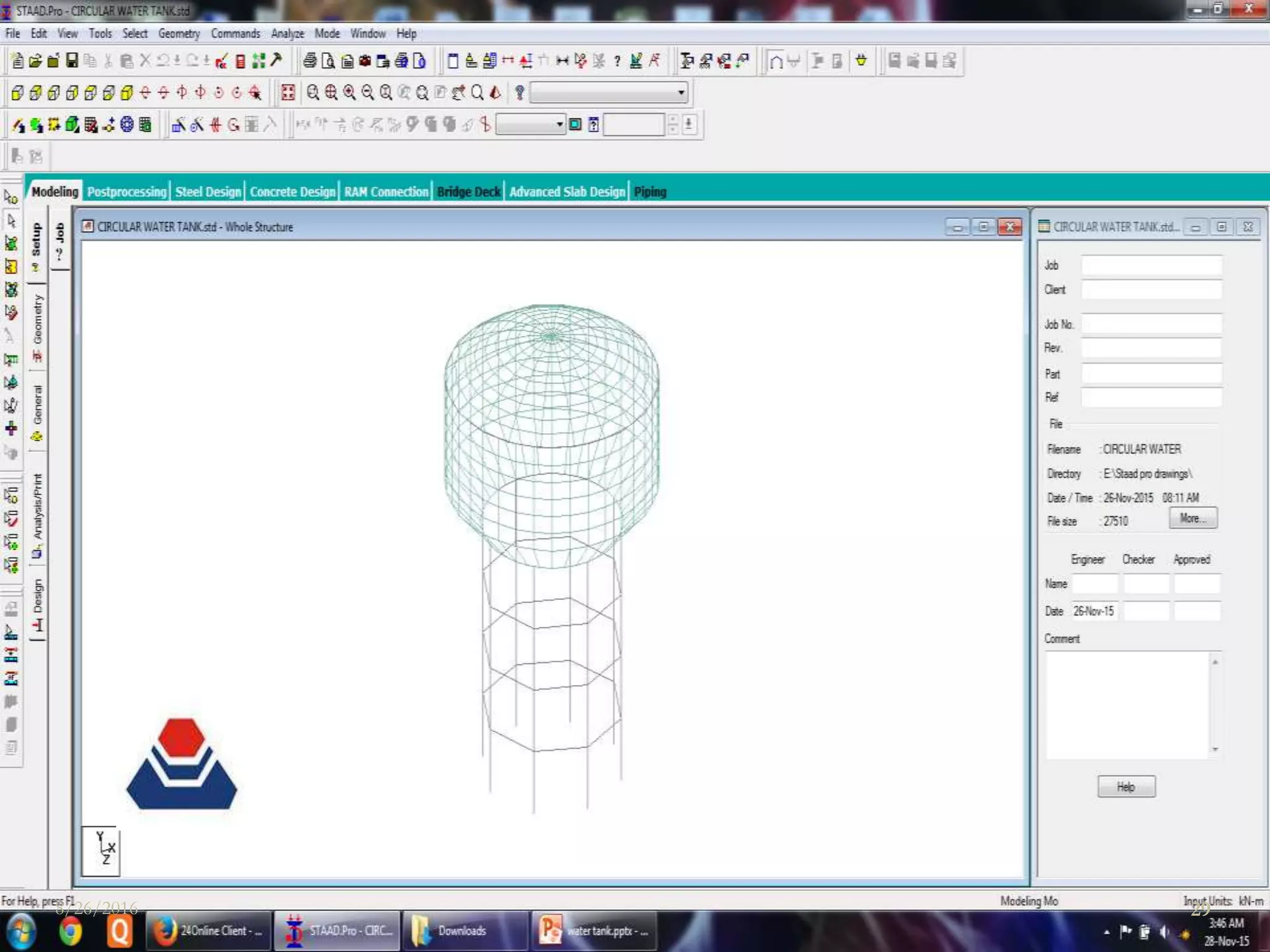

![(i) Water Supply Engineering by S.K.Garg

(ii) IS 2210-1988

(iii) Advanced Reinforced Concrete by H.J.Shah

(iv) IS 875 (Part 1 & 2)

(iv) IS-456:2000

(v) IS: 3370:2009 [Part-2]

(vi) Wikipedia

(vii) Softwares – AutoCAD & STAAD.Pro

8/26/2016 31](https://image.slidesharecdn.com/abhijitkumar-160826192300/75/Abhijit-kumar-31-2048.jpg)