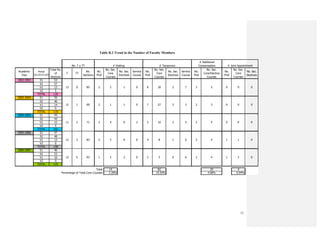

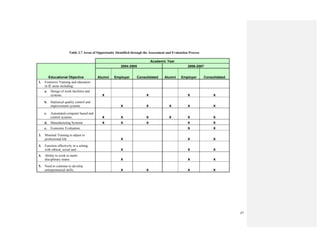

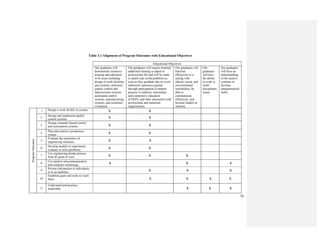

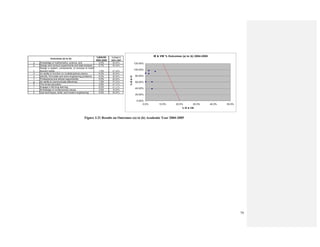

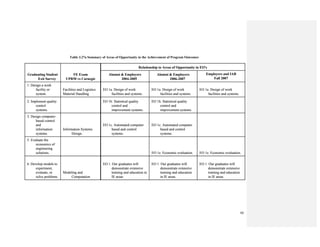

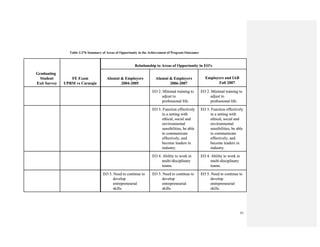

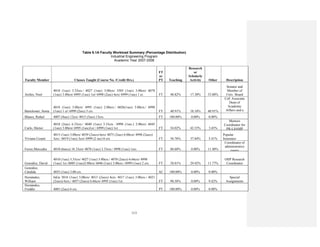

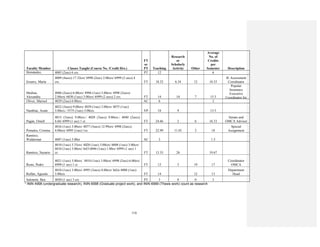

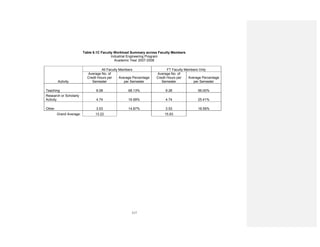

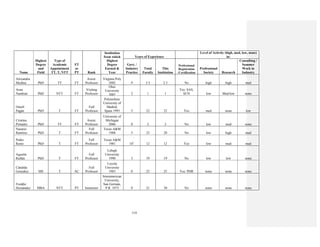

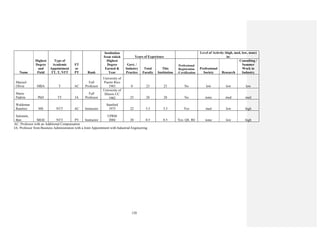

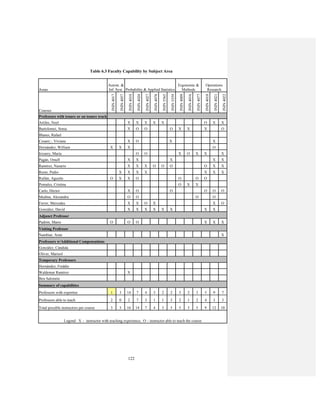

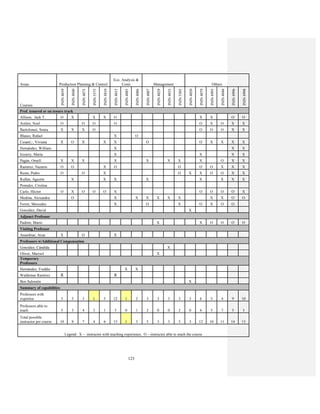

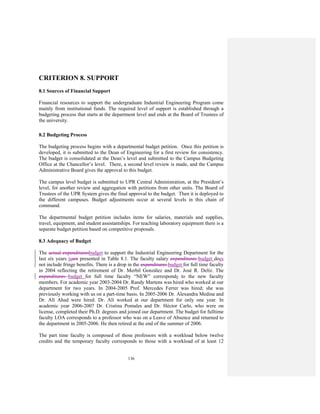

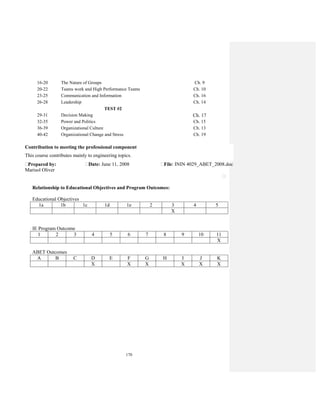

The Industrial Engineering program at the University of Puerto Rico Mayaguez conducted a self-study as part of its ABET accreditation process. The report details changes made since the previous review, including redesigning assessment metrics in response to concerns about measuring achievement of program objectives. It also shows that the percentage of required courses taught by temporary faculty has decreased from 40% to under 10% as more tenure-track faculty have been hired. The program aims to further improve faculty resources and continuous assessment.