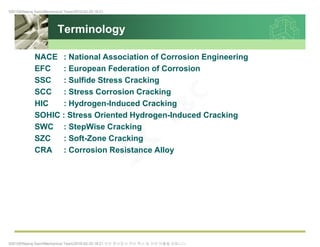

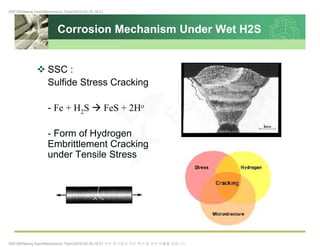

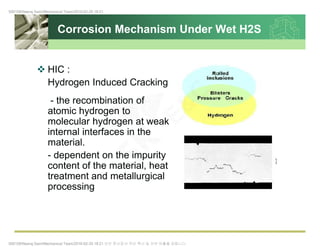

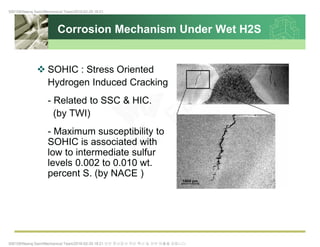

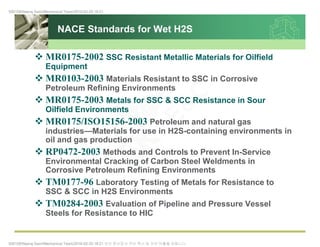

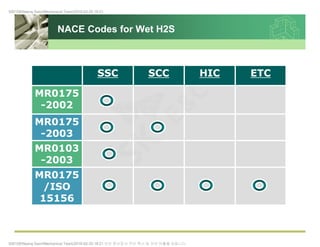

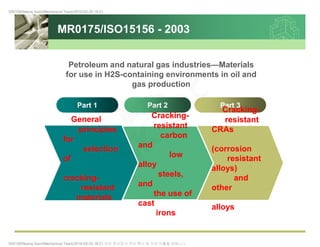

The document discusses corrosion mechanisms such as SSC, SCC, and HIC that can occur in wet H2S environments. It describes NACE standards for materials selection for resistance to these corrosion mechanisms, including MR0175/ISO15156 which provides guidelines for selecting cracking-resistant materials like steels, alloys, and cast irons. The standard has three parts that specify requirements for different material types and qualification methods through laboratory testing and field experience evaluation.