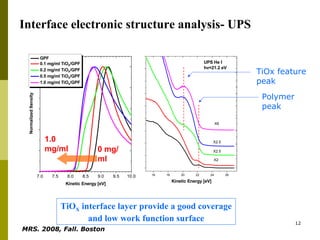

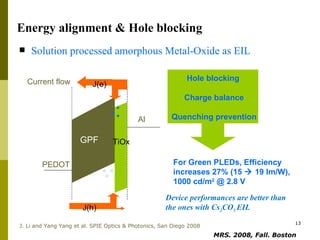

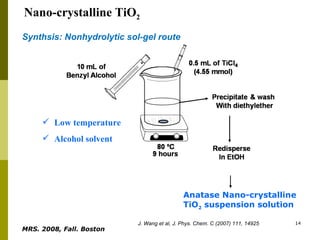

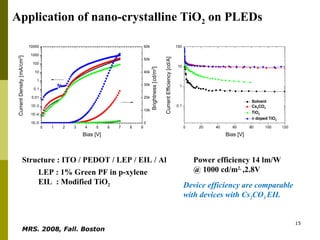

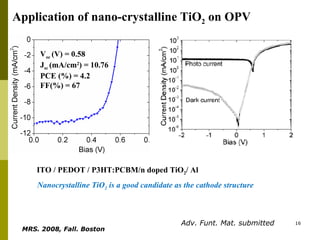

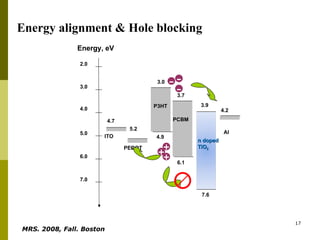

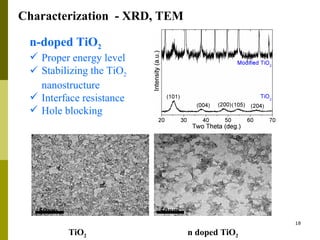

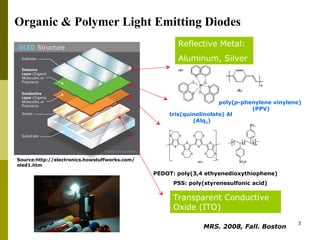

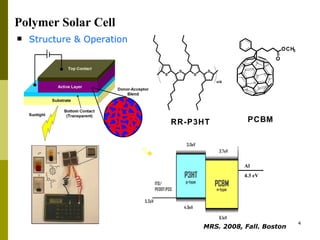

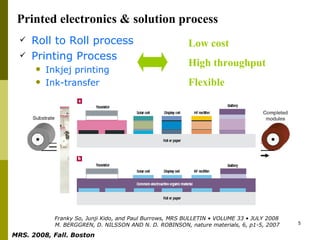

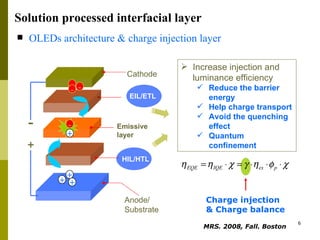

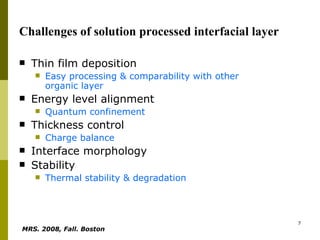

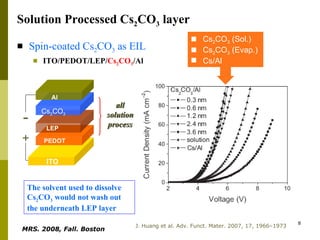

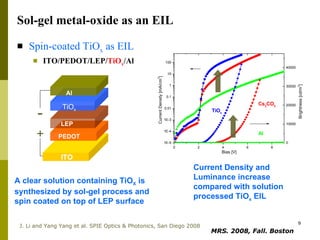

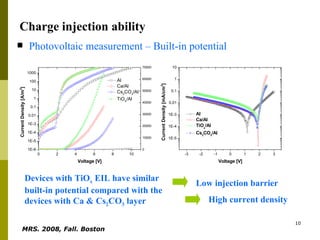

The document discusses the application of titanium oxide as an electron injection layer in organic optoelectronic devices through solution-based processes like sol-gel. It describes how amorphous and nano-crystalline titanium oxide synthesized by sol-gel and deposited via spin-coating can improve device performance when used as the electron injection layer in polymer LEDs and organic solar cells. Experimental results show that devices using the titanium oxide layer have higher efficiencies compared to those using other solution-processed layers like cesium carbonate. The document concludes that solution-processed titanium oxide is a promising material that can be employed as an electron injection layer for applications in printed electronics.

![Concentration dependence 2.97 6.04 17.3 6.4 1.0 mg/ml * Measured at the brightness of 1000 cd/m 2 13.52 18.98 3.67 Power Efficiency* [lm/W] 14.21 7.76 3.3 0.5 mg/ml 16.92 6.27 2.8 0.2 mg/ml 5.84 16.67 5.0 0.1 mg/ml Current* efficiency [cd/A] J* [mA/cm 2 ] Volt* [V] TiO X Conc.](https://image.slidesharecdn.com/MRS2008FallWalkerV2-123198165078-phpapp03/85/Mrs-2008-Fall-Walker-11-320.jpg)