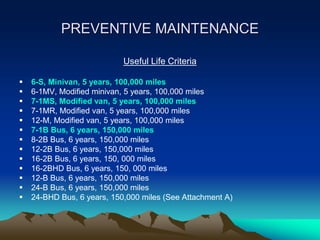

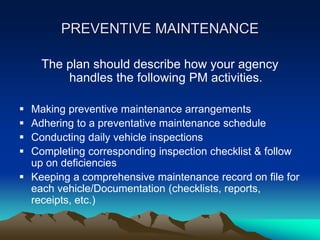

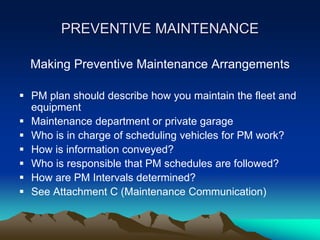

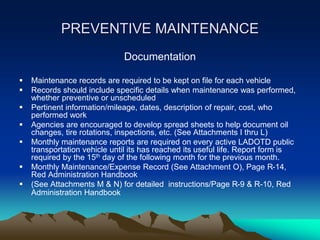

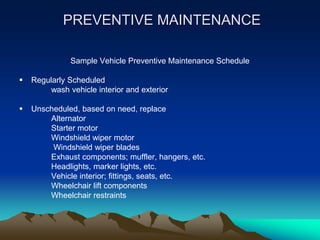

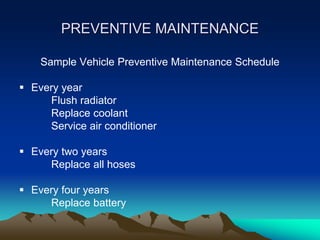

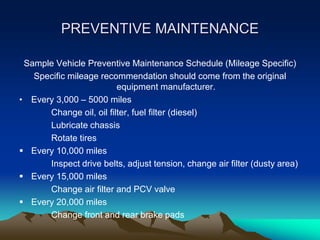

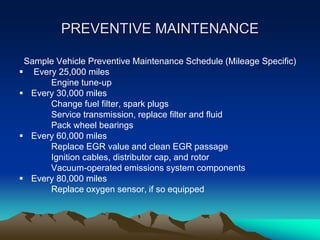

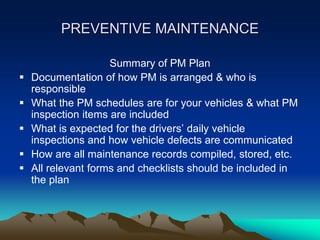

The document provides guidance on developing an effective preventive maintenance (PM) plan. It explains that PM involves scheduled maintenance activities aimed at preventing mechanical failures and ensuring safe vehicle operation. An effective PM plan should include adhering to maintenance schedules, conducting daily inspections, documenting inspections and repairs, and keeping comprehensive maintenance records for each vehicle. Sample PM schedules are provided based on mileage and time intervals. The document stresses the importance of documentation and record keeping to the success of the PM plan.