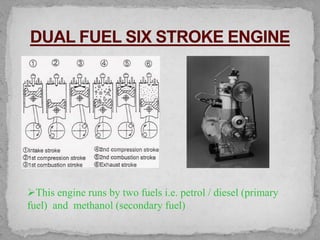

The seminar presentation by Sushang Shah covers six-stroke engines, an advancement over traditional four-stroke engines, highlighting different types, including dual fuel variants. The six-stroke engine notably reduces emissions and fuel consumption while offering higher efficiency but comes with increased size and manufacturing costs. Applications include commercial vehicles, agricultural machinery, and potential uses in aviation and marine sectors.

![Four stoke Six stroke

Engine Engine

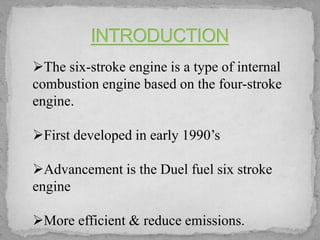

Engine type DI, Single cylinder, Air cooled, OHV

Bore x Stroke [mm] 82 x 78

Displacement [cc] 412

Top Clearance [mm] 0.9

Cavity Volume [cc] 16

Compression ratio 21

Intake Valve Open 100

BTDC 70

BTDC

Intake valve Close 1400

ABDC 1450

ABDC

Exhaust Valve Open 1350

BBDC 1400

BBDC

Exhaust Valve Close 120

ATDC 30

ATDC

Valve Overlap 220

100

Rated power 5.9 kW /3000rpm

Base Engine Test Engine](https://image.slidesharecdn.com/6strokeenginepptmudhf-191007225156/85/6-stroke-engine-12-320.jpg)

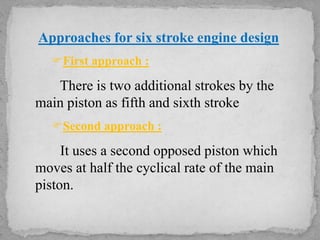

![Comparison between four stroke & six stroke petrol/diesel engines

Engine Parameters

Four Stroke

Engine

Six Stroke

Engine

Engine Speed Ne [rpm] 2007 2016

Supplied combustion heat per cycle

Qt [KJ/cycle] 0.50 0.68

Supplied combustion heat per unit time Ht [KJ/s]

8.36 7.62

Intake air flow per cycle

Ma [mg/cycle] 358.7 371.4

Injection quantity per cycle

Mf [mg/cycle] 11.8 16

Excess air ratio λ 2.40 1.83

Intake air flow per unit time

Ma [g/cycle] 6.00 4.16

Injection quantity per unit time

Mf [g/sec] 0.197 0.179

Brake torque Tb [N-m] 15.52 15.28

Brake power Lb [KW] 3.26 3.24

BSFC. b [ g / KW-h] 217.9 520.3

IMEP Pi [Kgf / cm2] 5.94 4.37

Indicated torque Ti [N-m] 19.10 18.71

Indicated power Li [KW] 4.01 3.75

ISFC bi [g / KW-h ] 177.2 163.3](https://image.slidesharecdn.com/6strokeenginepptmudhf-191007225156/85/6-stroke-engine-13-320.jpg)

![Four Stroke

Engine

Six Stroke

Engine

Dual Fuel Six

Stroke Engine

Nitrous Oxide [ppm]

( % improvement) 768

113

(85.3%)

90.5

(88.2%)

Soot [%]

(%improvement) 6.8

28.8

(- 323.5%)

0

(100%)

Indicated specific heat consumption

bi’ [MJ/KW-h]

(% improvement)

7.51 6.61

(12.0%)

6.37

(15.2%)](https://image.slidesharecdn.com/6strokeenginepptmudhf-191007225156/85/6-stroke-engine-14-320.jpg)