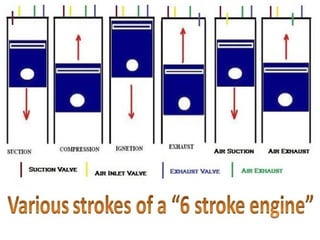

This document summarizes and compares a 4-stroke and 6-stroke internal combustion engine. It explains that a 6-stroke engine adds two additional strokes - an air intake stroke and air exhaust stroke - to the standard 4-stroke cycle. This captures normally wasted heat to power an additional piston stroke, thereby increasing fuel efficiency by up to 50%. The 6-stroke engine also generates less pollution and heat compared to a 4-stroke while maintaining similar power levels. In conclusion, 6-stroke engine technology promises more efficient use of fossil fuels and could help transition to an era with limited oil reserves.