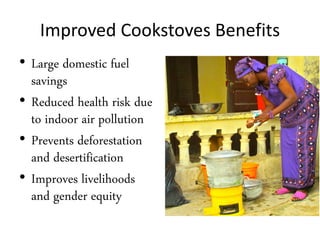

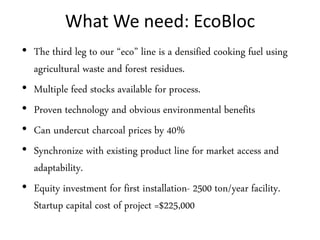

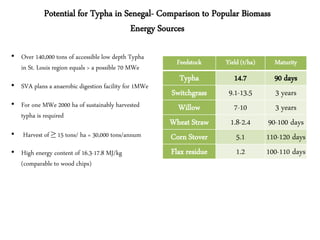

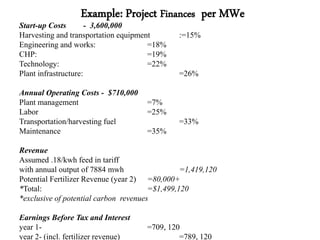

(1) The document discusses improved cookstoves and densified cooking fuel products that provide environmental and social benefits in Senegal. (2) It seeks an equity investment of $225,000 for a 2500 ton per year facility producing the densified cooking fuel. (3) The document also presents a concept for a 1 megawatt electricity project using Typha biomass that could generate over $700,000 in annual revenue while providing nutrient removal and carbon credit benefits.