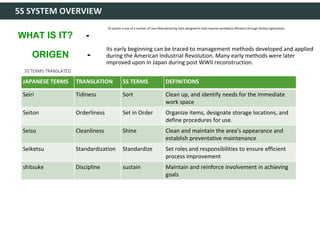

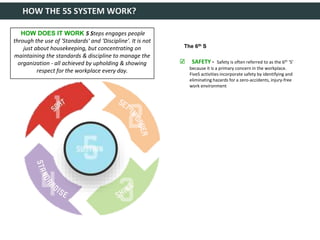

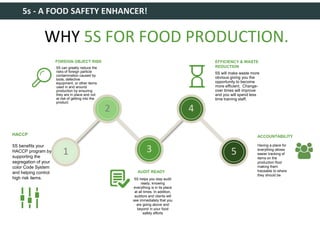

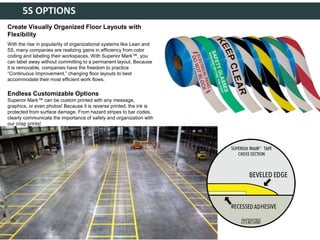

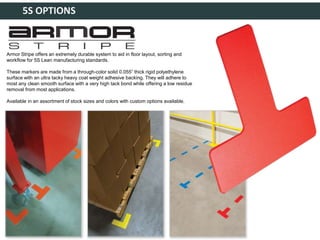

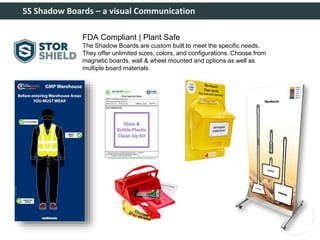

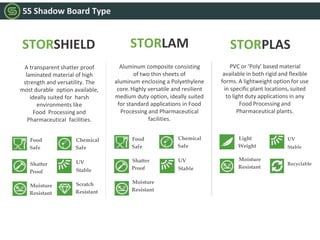

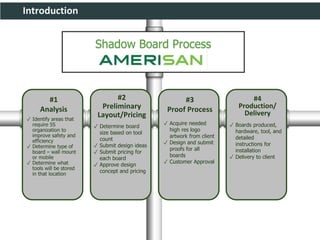

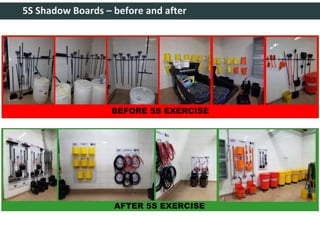

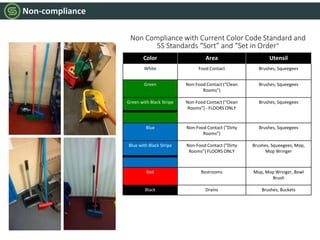

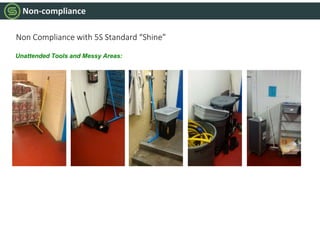

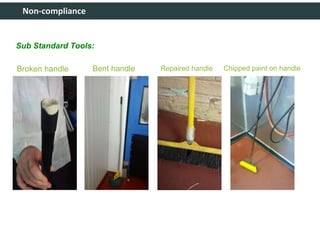

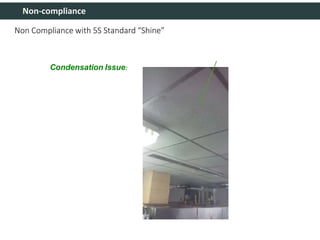

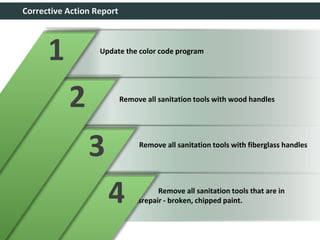

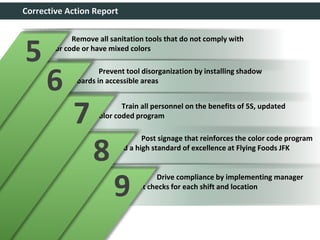

The document outlines the implementation of a 5S sanitation program aimed at improving workplace efficiency and safety through organization. It details the five principles—Sort, Set in Order, Shine, Standardize, and Sustain—and emphasizes the use of color-coded tools for better tracking and contamination prevention in food production. The document also highlights the importance of visual communication and customization in maintaining 5S standards and outlines corrective actions for non-compliance with these practices.