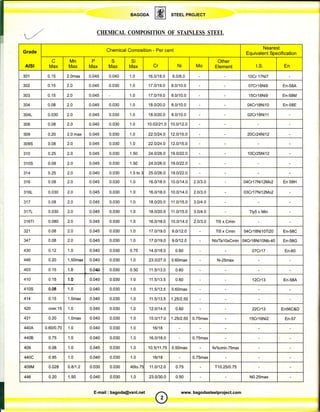

The document lists various grades of stainless steel, their chemical compositions in terms of percentages of carbon, manganese, phosphorus, sulfur, silicon and other elements. For each grade, it provides the range of percentages for key elements like chromium, nickel, molybdenum that make the steel stainless, as well as any additional specifications or equivalent grades. Over 30 grades of stainless steel are listed along with their chemical make-up and specifications.