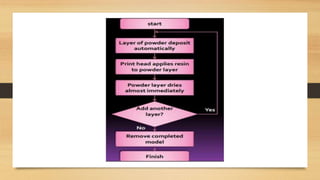

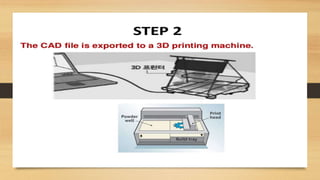

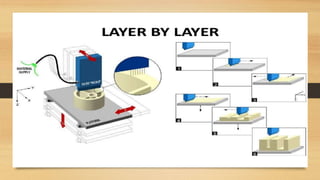

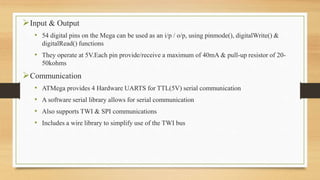

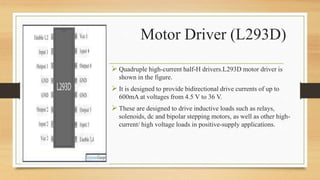

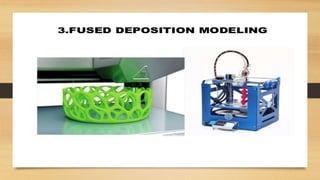

This document discusses the components and process of 3D printing. It includes a block diagram of the components which are an Arduino Mega 2560 microcontroller, L293D motor driver, stepper motor, and extruder. It describes the printing materials of ABS and PLA. It explains the methods of 3D printing including fused deposition modeling and stereolithography. The advantages are listed as rapid prototyping, clean process, and ability to produce complex shapes, while disadvantages include slow speed and limited strength of components.