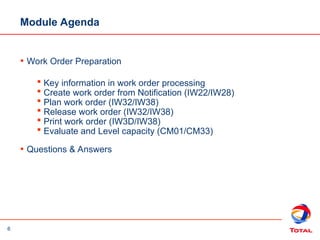

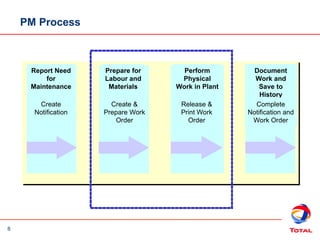

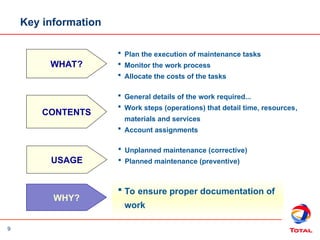

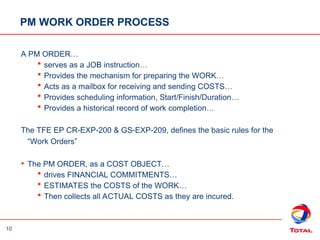

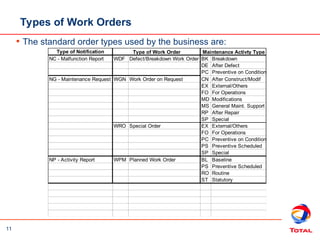

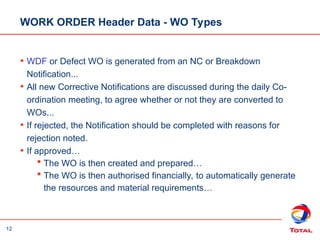

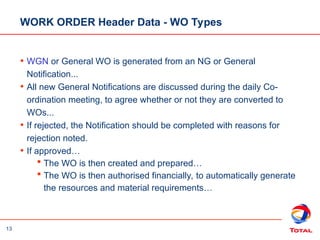

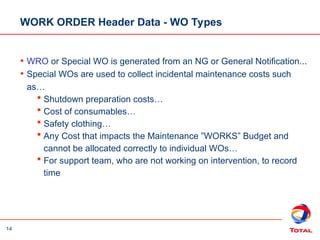

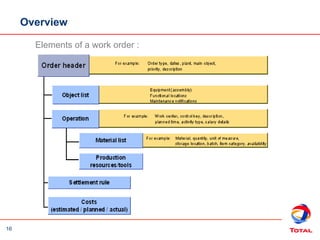

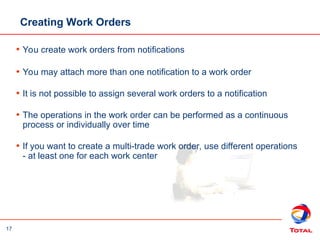

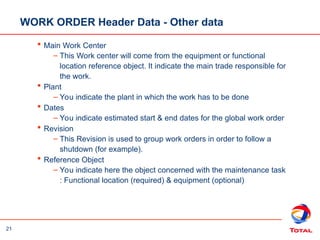

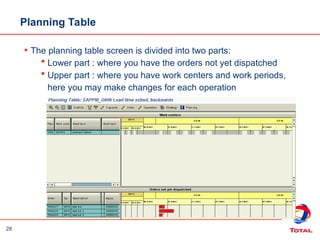

This document outlines a training course for SAP work orders, covering key information on preparation, creation, planning, and execution of maintenance tasks. It details types of work orders, the importance of efficient maintenance processes, and the role of work orders in documenting costs and scheduling. The document also includes an agenda for the training sessions, as well as guidelines for creating and managing work orders within SAP.