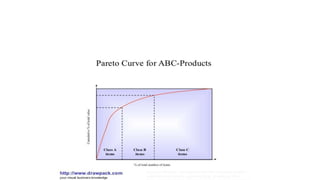

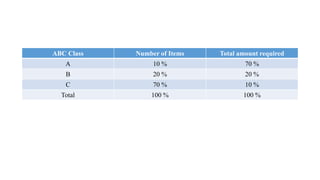

This document provides information about inventory control systems. It describes the meaning of inventory as stock that a company manufactures for sale. It then classifies inventory control systems into two types: continuous review (Q-system) and periodic review (P-system). The continuous review system records inventory balances after each transaction, while the periodic review system only counts inventory at specific time intervals. The document also explains the ABC classification system which ranks inventory items into three categories based on their importance to achieve business goals.