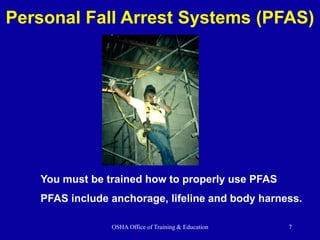

Scaffolds are elevated temporary work platforms used in construction that expose workers to fall, electrocution, and falling object hazards. The document outlines OSHA regulations for safely constructing different types of scaffolds through proper guarding, fall protection, inspection, training, and oversight by a competent person. Key requirements include ensuring stable construction and access, protecting against falls, inspecting scaffolds before each shift, and training workers on scaffold hazards and safety procedures.