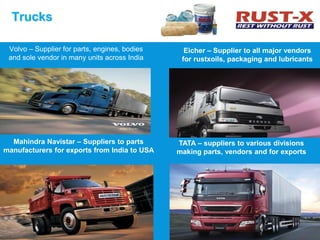

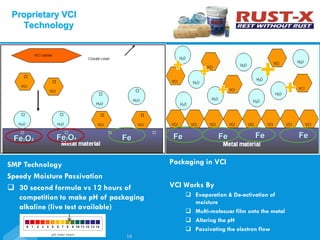

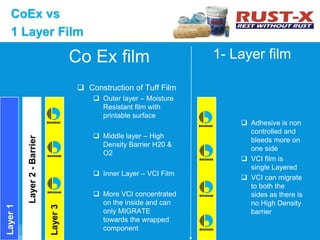

RDM RustX USA manufactures and exports VCI packaging products from facilities in the USA, India, Italy, France, and Thailand. It has over 800 employees globally and serves over 10,000 customers in 25 countries. The document provides details on RDM RustX's product offerings, major clients in various industries, proprietary VCI technologies, global manufacturing sites, leadership team, and values.