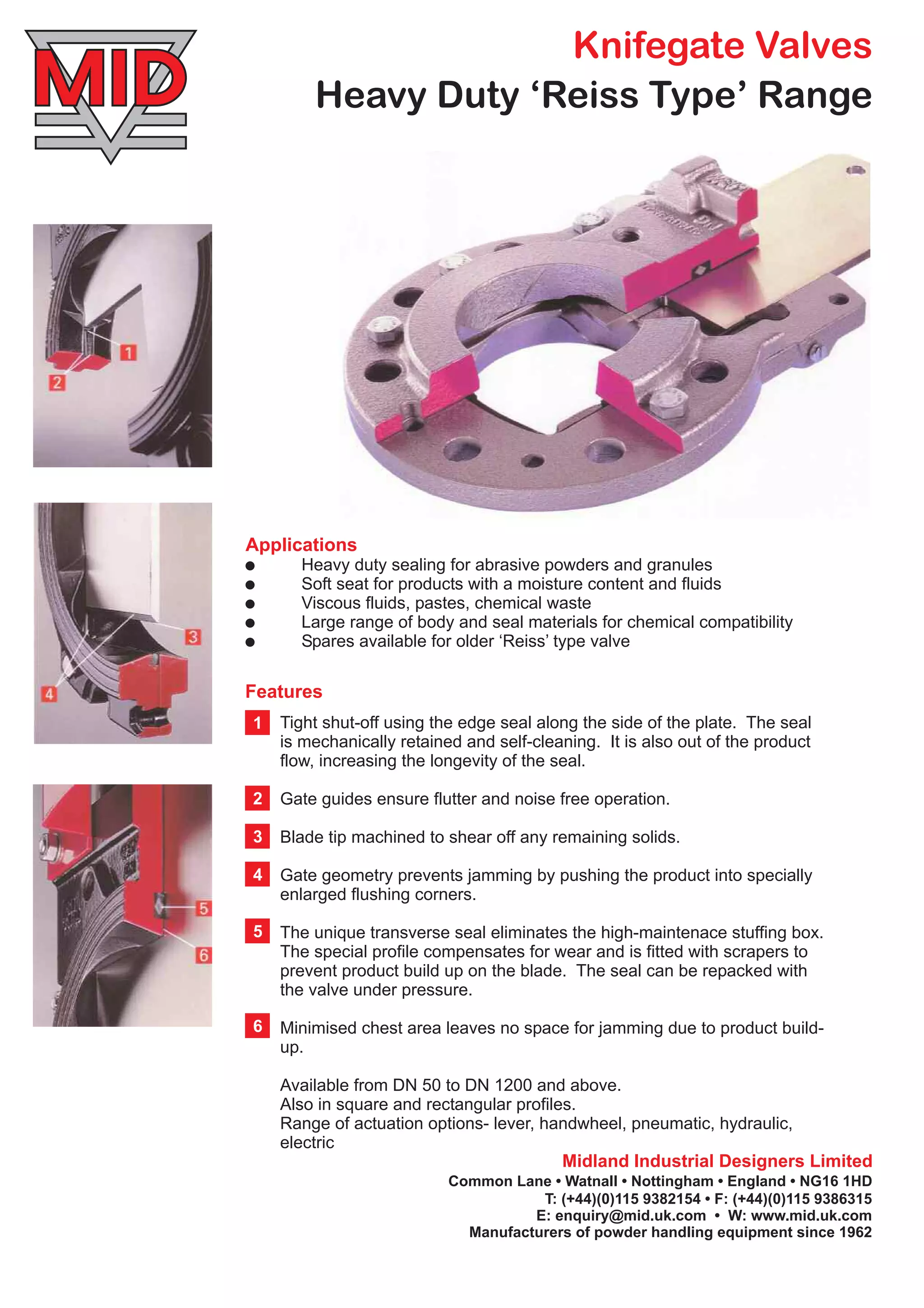

Knifegate valves are designed for use with abrasive powders, granules, viscous fluids, and pastes. They feature a self-cleaning edge seal along the side of the plate to provide tight shut-off. Gate guides ensure flutter-free operation and the blade tip is machined to shear off remaining solids. A range of body and seal materials provide chemical compatibility and sizes are available from 50 to 1200mm.