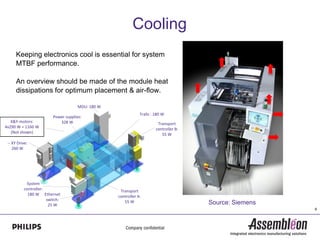

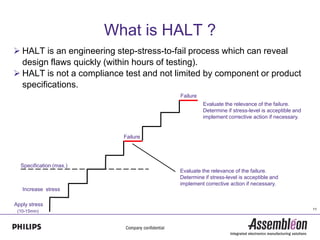

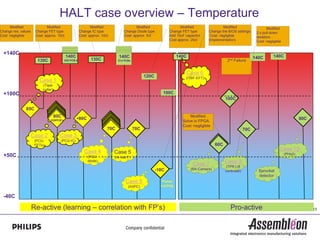

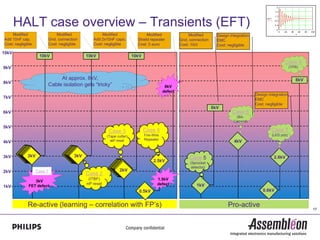

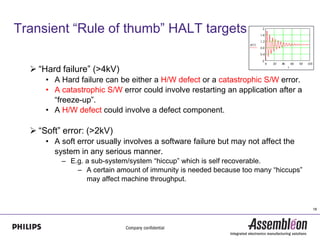

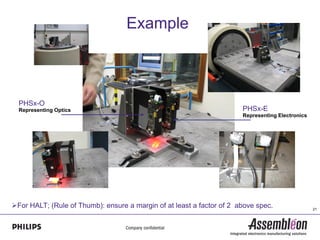

The document discusses trends in product creation processes towards shorter development times, higher integration, and more stringent quality demands. It emphasizes the importance of evaluating modules through environmental stress testing like HALT before system integration to ensure reliability in the intended system environment which can subject modules to heat, shock, vibration and other stresses. The results of HALT testing are presented as a case study that identified design flaws and led to modifications to improve the design margin and reliability of integrated systems.

![Arrhenius law in lifetime acceleration for electronics

Tacc =exp[(Ea/k)*(1/Ta - 1/T)]

Thermal acceleration of failure rate

1.0E-01

Factor 811

Factor 452

1.0E-02

Factor 244

Reaction rate

Factor 127

1.0E-03

Factor 31

Factor 6 Ea = 0.72

1.0E-04

K = Boltzmann’s constant

Factor 2,6

T = Kelvin

1.0E-05

20 40 60 80 100 120 140 160

Temperature oC 8](https://image.slidesharecdn.com/13-20hrbrett-100616020525-phpapp01/85/13-20-Ray-Brett-8-320.jpg)