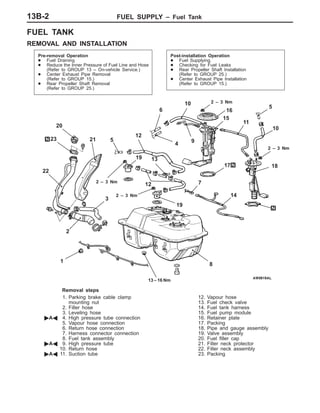

The document provides instructions for fuel tank removal and installation, fuel pump module inspection, and fuel pump module disassembly and reassembly. It includes:

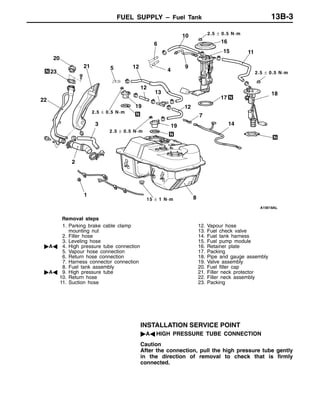

1) Steps for removing and installing the fuel tank, which involves disconnecting fuel lines and hoses, removing mounting nuts, and reconnecting lines post-installation.

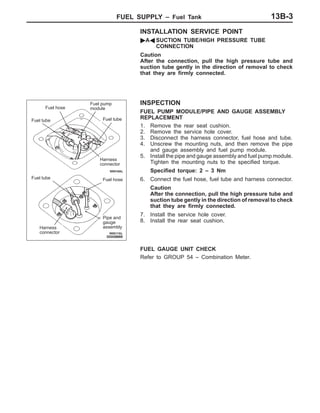

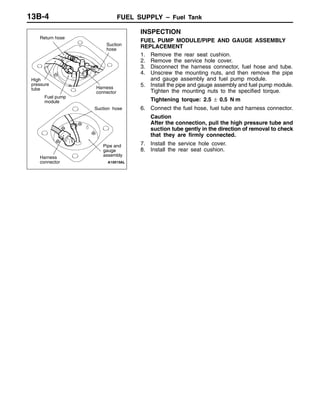

2) Inspection instructions for replacing the fuel pump module and pipe/gauge assembly, including disconnecting components, loosening nuts, reinstalling securely, and reconnecting.

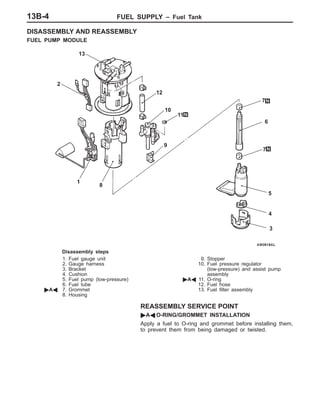

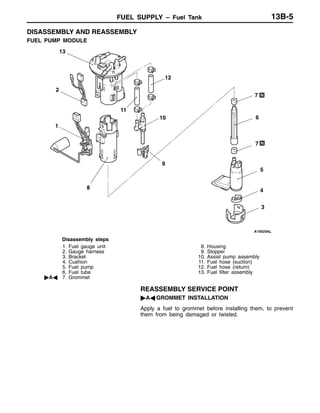

3) Disassembly steps for the fuel pump module and a service point about applying fuel to grommets during reassembly.