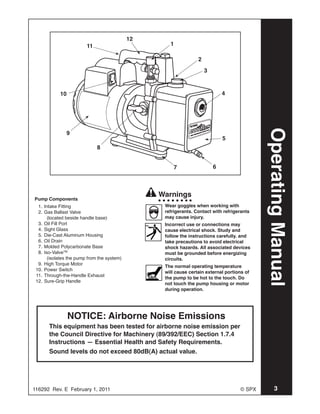

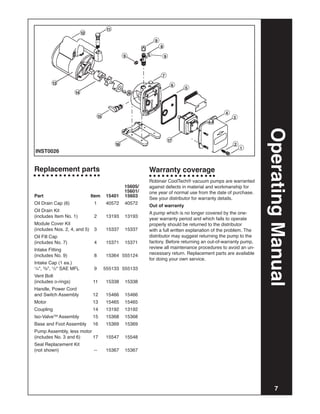

This document is an operating manual for CoolTech high performance vacuum pumps. It provides specifications for several pump models, describes pump components, gives warnings and operating instructions, and provides a troubleshooting guide. The manual emphasizes the pumps' high vacuum capability, gas ballast feature to prevent condensation, and lifetime filtration system. Maintenance instructions include changing the pump oil after each use to maintain performance.