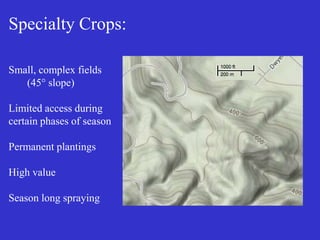

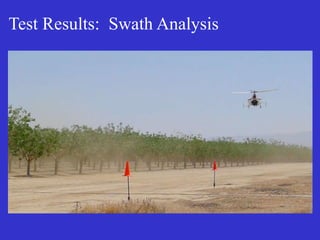

This document summarizes a project testing the use of unmanned aircraft for spraying specialty crops. Key findings include:

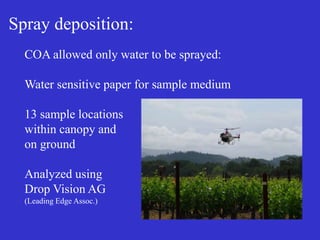

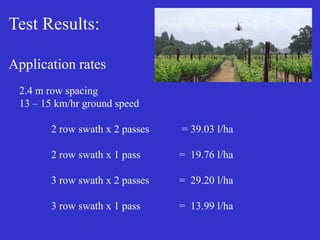

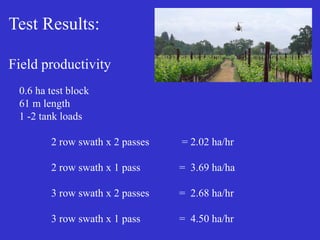

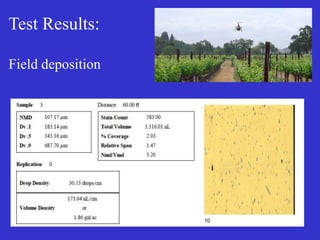

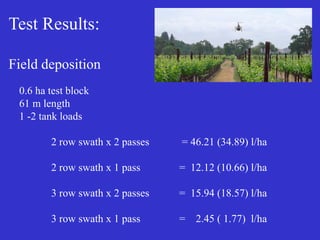

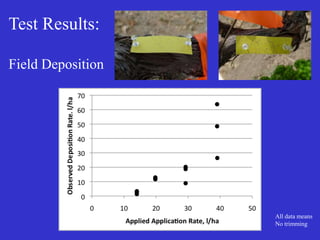

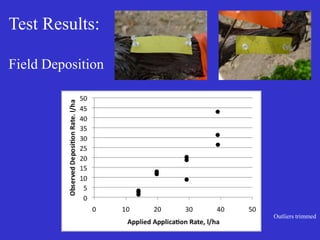

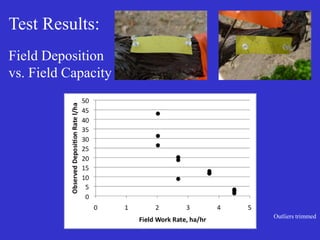

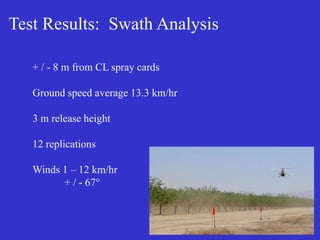

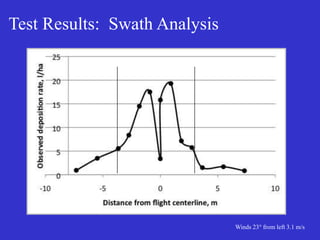

- Testing showed unmanned aircraft can spray vineyards and orchards effectively, achieving deposition rates of 12-46 l/ha. However, increasing application rates significantly reduced field productivity.

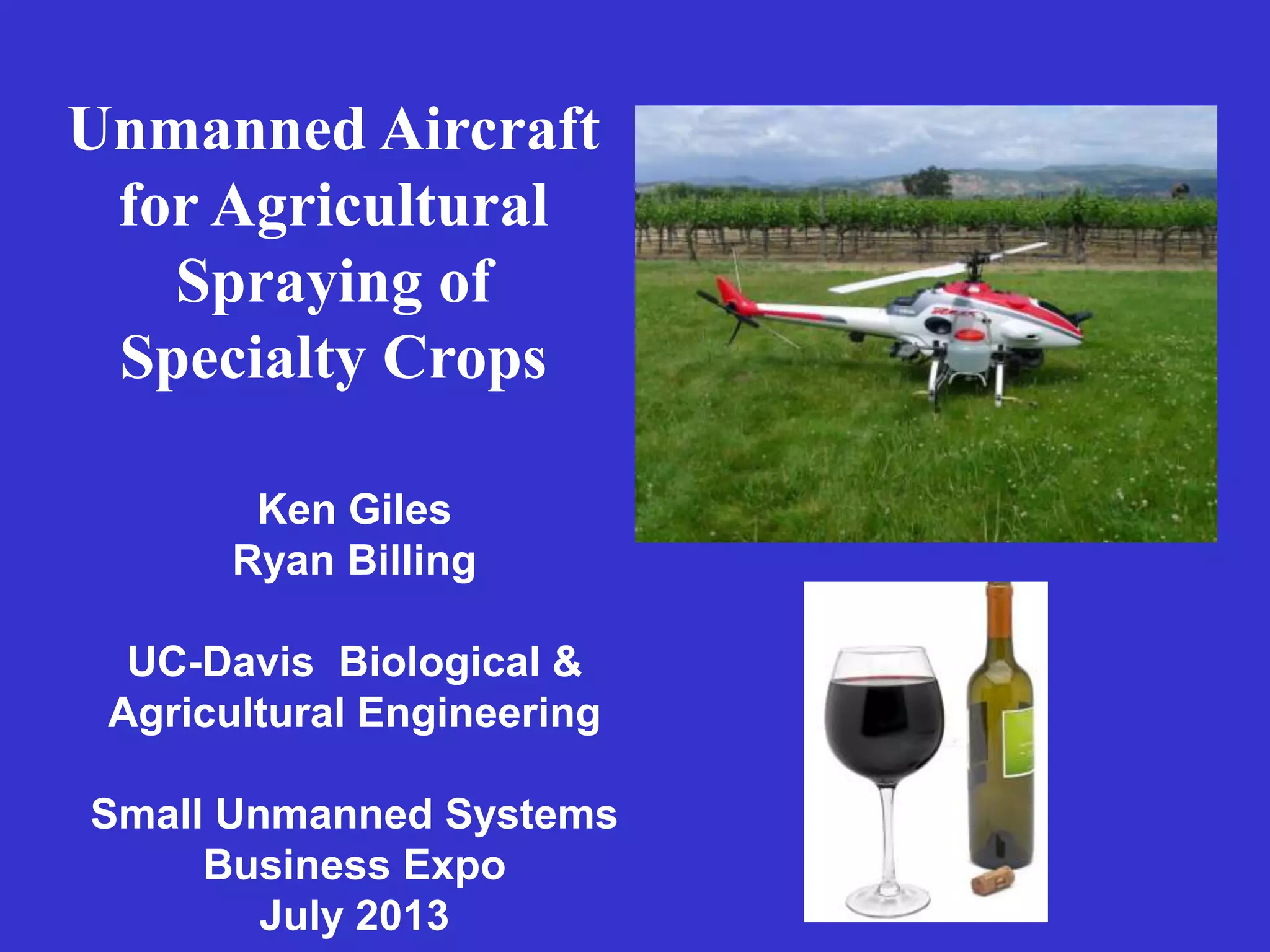

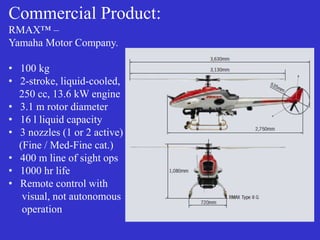

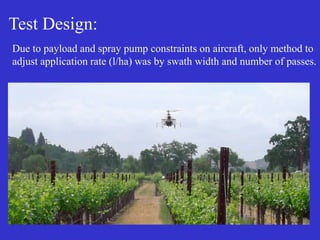

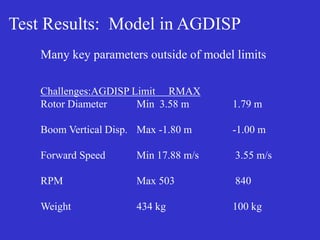

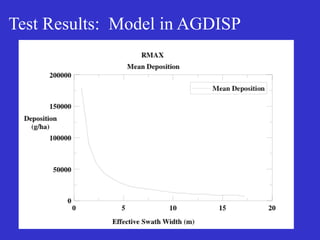

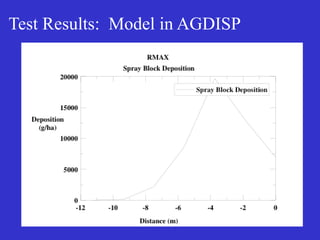

- A Yamaha RMAX aircraft was used, which is suitable for low-volume, small-droplet spraying but its parameters exceeded AGDISP modeling guidelines.

- Future work will involve spraying active ingredients to assess efficacy, measuring off-target drift, developing business cases, and pursuing regulatory approval to address permitting and labeling.