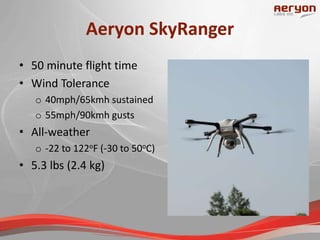

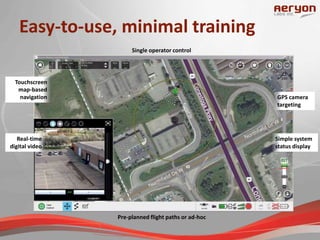

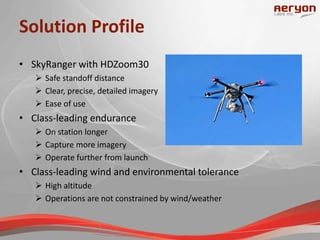

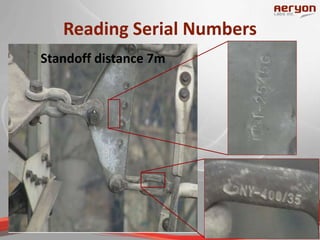

Dave Kroetsch presented on using small unmanned aerial systems (sUAS) for infrastructure inspection. He discussed the challenges of power line inspection using manned aircraft or climbing towers, and how sUAS can overcome these challenges by maintaining a safe standoff distance while still providing high-resolution imagery. Examples were given of using Aeryon Labs' SkyRanger sUAS equipped with an HDZoom30 camera to inspect power lines from hundreds of feet away. The sUAS solution allows for safer, more efficient inspections compared to traditional methods.