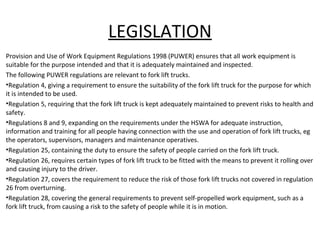

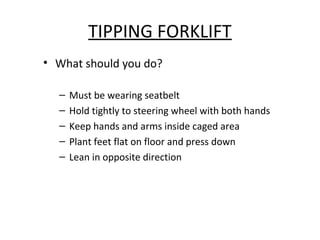

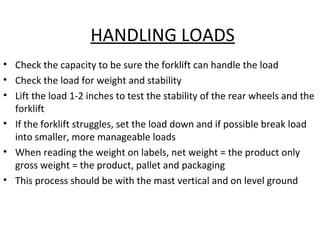

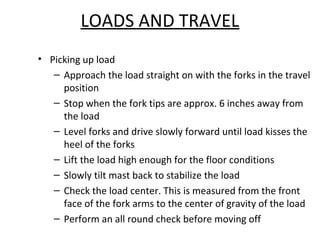

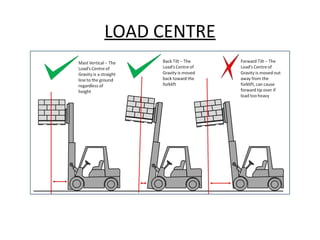

The document provides an overview of forklift operator safety training. It covers legislation requirements, pre-use checks of forklifts, safe operating practices like looking in the direction of travel and applying the parking brake before operating hydraulics. It also discusses safely handling loads and their effect on forklift stability, as well as operating on slopes, parking procedures, and pedestrian safety. The conclusion emphasizes that forklifts require pre-use checks, loads impact stability, and operators must watch out for hazards and pedestrians.