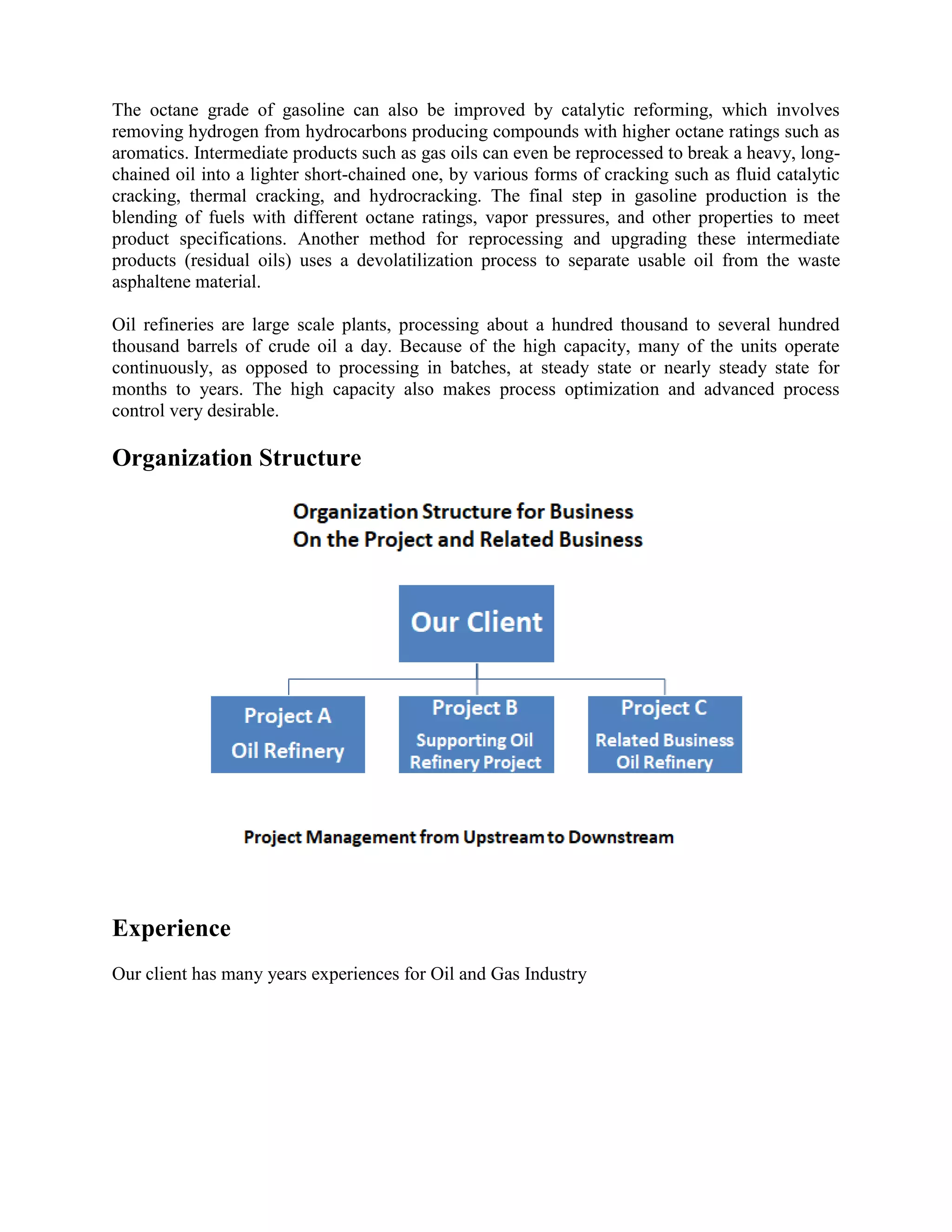

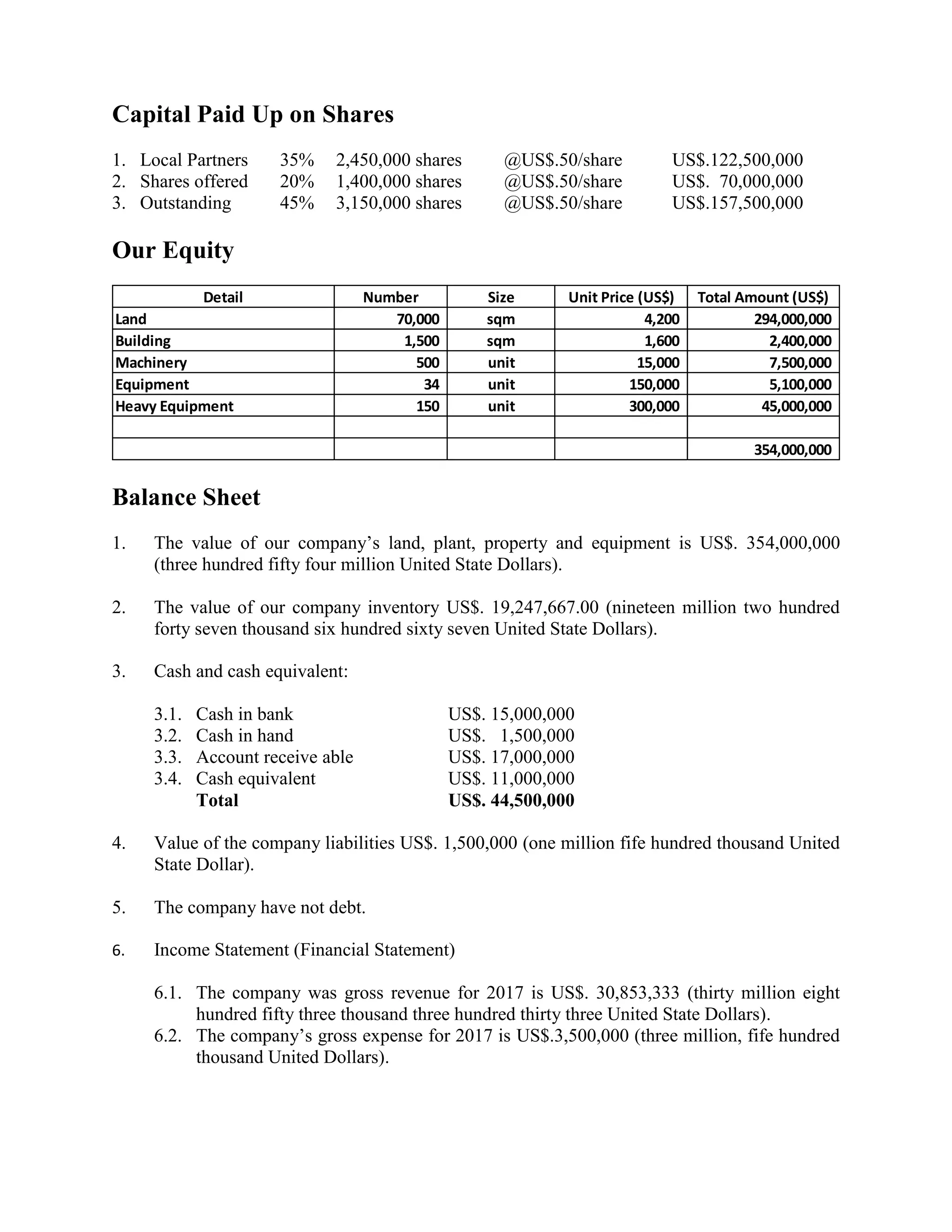

PT W2P Manajemen Bisnis is an Indonesian engineering and project management company focused on providing solutions for oil refinery projects, aiming to become a market leader in the oil and gas industry. The document details the company's objectives, capital structure, planned refinery operations, and financial projections, highlighting a need for $70 million in capital to expand their refinery and related infrastructure. The company also outlines various petroleum products produced and business strategies for optimizing operations and increasing efficiency.