Material selection for different components

•

1 like•731 views

Medium carbon steel is selected for the design because it has a high performance index and low cost. Polytetrafluoroethylene (PTFE) GF1 is selected, despite its high cost, for safety purposes. Wrought Ferritic Stainless Steel is selected because it has a good performance index and good thermal properties. Common hard brick is selected for its low cost, good thermal conduction, and ease of manufacture. Nodular (spheroidal, ductile) Cast Iron is selected for its good performance index and low cost. Low Carbon steel is suitable for designs requiring a material that is low cost, stiff, and strong.

Report

Share

Report

Share

Download to read offline

Recommended

Grain refinement, which is obtained by changing the size of grain structure by different techniques, is a preferred method to improve simultaneously the strength and plasticity of metallic materials.

The presentation involves "Principles of Equal-channel Angular Pressing as a processing tool for grain refinement", its applications and advantages in the field of technology and research.Advanced Material science - Grain Refinement

Advanced Material science - Grain RefinementCIPET | Central Institute of Petrochemicals Engineering & Technology

Recommended

Grain refinement, which is obtained by changing the size of grain structure by different techniques, is a preferred method to improve simultaneously the strength and plasticity of metallic materials.

The presentation involves "Principles of Equal-channel Angular Pressing as a processing tool for grain refinement", its applications and advantages in the field of technology and research.Advanced Material science - Grain Refinement

Advanced Material science - Grain RefinementCIPET | Central Institute of Petrochemicals Engineering & Technology

More Related Content

What's hot

What's hot (20)

Advances in Special Steel: Maraging steel updated 2016

Advances in Special Steel: Maraging steel updated 2016

Expandable Pattern Casting and Plaster Mold Casting

Expandable Pattern Casting and Plaster Mold Casting

All About material selection for product design and development

All About material selection for product design and development

Viewers also liked

Viewers also liked (12)

TALAT Lecture 1502: Criteria in Material Selection

TALAT Lecture 1502: Criteria in Material Selection

Webinar - Adobe Photoshop for Advanced Beginners - 2016-03-10

Webinar - Adobe Photoshop for Advanced Beginners - 2016-03-10

SELECTION OF MATERIAL HANDLING SYSTEM USING MULTI CRITERIA DECISION TECHNIQUE...

SELECTION OF MATERIAL HANDLING SYSTEM USING MULTI CRITERIA DECISION TECHNIQUE...

Similar to Material selection for different components

Similar to Material selection for different components (20)

Design Project - Electric Furnace for Steel Making

Design Project - Electric Furnace for Steel Making

Optimization of spheroidized annealing process parameters on AISI 10B21 steel...

Optimization of spheroidized annealing process parameters on AISI 10B21 steel...

IRJET-Effect of Chemical Composition on Total Carbon Equivalent in Grey Iron ...

IRJET-Effect of Chemical Composition on Total Carbon Equivalent in Grey Iron ...

Analysis and Improvement of Distortion of Lathe Machine Main Spindle

Analysis and Improvement of Distortion of Lathe Machine Main Spindle

Buckling Analysis of Cold Formed Steel Compression Members at Elevated Temper...

Buckling Analysis of Cold Formed Steel Compression Members at Elevated Temper...

Optimization of Hybrid Aluminium Metal Matrix Composite Through Taguchi Method

Optimization of Hybrid Aluminium Metal Matrix Composite Through Taguchi Method

FRACTOGRAPHY OF CRYOGENIC CHILL CASTED ASTM A 494 M GRADE NICKEL ALLOY METAL ...

FRACTOGRAPHY OF CRYOGENIC CHILL CASTED ASTM A 494 M GRADE NICKEL ALLOY METAL ...

Machining Of an Aluminum Metal Matrix Composite Using Tungsten Carbide Inserts

Machining Of an Aluminum Metal Matrix Composite Using Tungsten Carbide Inserts

IRJET- A Study on Effect of SIC on Mechanical Properties of Aluminium 8011 Me...

IRJET- A Study on Effect of SIC on Mechanical Properties of Aluminium 8011 Me...

IRJET- Effect of Tempering Process on EN-24 Steel Alloy

IRJET- Effect of Tempering Process on EN-24 Steel Alloy

IRJET- Effect of Tempering Process on EN-24 Steel Alloy

IRJET- Effect of Tempering Process on EN-24 Steel Alloy

Buckling Analysis of Cold Formed Steel Compression Members at Elevated Temper...

Buckling Analysis of Cold Formed Steel Compression Members at Elevated Temper...

FABRICATION OF LM6/B4C/GR ALUMINIUM METAL MATRIX COMPOSITE

FABRICATION OF LM6/B4C/GR ALUMINIUM METAL MATRIX COMPOSITE

Experimental and Microstructural Analysis of TIG and MIG Welding on Dissimila...

Experimental and Microstructural Analysis of TIG and MIG Welding on Dissimila...

Recently uploaded

Call Girl Meerut Indira Call Now: 8617697112 Meerut Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Meerut Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Meerut understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Call Girl Aurangabad Indira Call Now: 8617697112 Aurangabad Escorts Booking Contact Details WhatsApp Chat: +91-8617697112 Aurangabad Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable. Independent Escorts Aurangabad understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together. We provide –(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Call girls in delhi ✔️✔️🔝 9953056974 🔝✔️✔️Welcome To Vip Escort Services In Delhi [ ]Noida Gurgaon 24/7 Open Sex Escort Services With Happy Ending ServiCe Done By Most Attractive Charming Soft Spoken Bold Beautiful Full Cooperative Independent Escort Girls ServiCe In All-Star Hotel And Home Service In All Over Delhi, Noida, Gurgaon, Faridabad, Ghaziabad, Greater Noida,

• IN CALL AND OUT CALL SERVICE IN DELHI NCR

• 3* 5* 7* HOTELS SERVICE IN DELHI NCR

• 24 HOURS AVAILABLE IN DELHI NCR

• INDIAN, RUSSIAN, PUNJABI, KASHMIRI ESCORTS

• REAL MODELS, COLLEGE GIRLS, HOUSE WIFE, ALSO AVAILABLE

• SHORT TIME AND FULL TIME SERVICE AVAILABLE

• HYGIENIC FULL AC NEAT AND CLEAN ROOMS AVAIL. IN HOTEL 24 HOURS

• DAILY NEW ESCORTS STAFF AVAILABLE

• MINIMUM TO MAXIMUM RANGE AVAILABLE.

Call Girls in Delhi & Independent Escort Service –

CALL GIRLS SERVICE DELHI NCR

Vip call girls in Delhi

Call Girls in Delhi, Call Girl Service 24×7 open

Call Girls in Delhi Best Delhi Escorts in Delhi

Low Rate Call Girls In Saket Delhi

X~CALL GIRLS IN Ramesh Nagar Metro

best Delhi call girls and Delhi escort service.

CALL GIRLS SERVICE IN ALL DELHI …

(Delhi) Call Girls in (Chanakyapuri)

Hot And Sexy Independent Model Escort Service In Delhi Unlimited Enjoy Genuine 100% Profiles And Trusted Door Step Call Girls Feel Free To Call Us Female Service Hot Busty & Sexy Party Girls Available For Complete Enjoyment. We Guarantee Full Satisfaction & In Case Of Any Unhappy Experience, We Would Refund Your Fees, Without Any Questions Asked. Feel Free To Call Us Female Service Provider Hours Opens Thanks.

Delhi Escorts Services 100% secure Services.Incall_OutCall Available and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services all over Delhi NCR.

Delhi All Hotel Services available 3* 4* 5* Call Call

Delhi Escorts Services And Delhi Call Girl Agency 100% secure Services in my agency. Incall and outcall Services provide.

We are available 24*7 for Full Night and short Time Escort Services my agency in all over New Delhi

Delhi All Hotel Services available my agency

SERVICES [✓✓✓]

Housewife

College Girl

VIP Escort

Independent Girl

Aunty

Without a Condom sucking )?

Sexy Aunty.DSL (Dick Sucking Lips)?

DT (Dining at the Toes English Spanking)

Doggie (Sex style from no behind)??

OutCall- All Over Delhi Noida Gurgaon 24/7

FOR APPOINTMENT Call/Whatsop / 9953056974Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Sex Service At Affordable Rate

Booking Contact Details

WhatsApp Chat: +91-6297143586

pune Escort Service includes providing maximum physical satisfaction to their clients as well as engaging conversation that keeps your time enjoyable and entertaining. Plus they look fabulously elegant; making an impressionable.

Independent Escorts pune understands the value of confidentiality and discretion - they will go the extra mile to meet your needs. Simply contact them via text messaging or through their online profiles; they'd be more than delighted to accommodate any request or arrange a romantic date or fun-filled night together.

We provide -

01-may-2024(v.n)

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...Call Girls in Nagpur High Profile

Recently uploaded (20)

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Meerut Call Now 8617697112 Meerut Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Ankleshwar 7001035870 Whatsapp Number, 24/07 Booking

CCS335 _ Neural Networks and Deep Learning Laboratory_Lab Complete Record

CCS335 _ Neural Networks and Deep Learning Laboratory_Lab Complete Record

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

Roadmap to Membership of RICS - Pathways and Routes

Roadmap to Membership of RICS - Pathways and Routes

Call Girls Wakad Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls Wakad Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Ramesh Nagar Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call for Papers - African Journal of Biological Sciences, E-ISSN: 2663-2187, ...

Call for Papers - African Journal of Biological Sciences, E-ISSN: 2663-2187, ...

The Most Attractive Pune Call Girls Budhwar Peth 8250192130 Will You Miss Thi...

The Most Attractive Pune Call Girls Budhwar Peth 8250192130 Will You Miss Thi...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Top Rated Pune Call Girls Budhwar Peth ⟟ 6297143586 ⟟ Call Me For Genuine Se...

Double Revolving field theory-how the rotor develops torque

Double Revolving field theory-how the rotor develops torque

Intze Overhead Water Tank Design by Working Stress - IS Method.pdf

Intze Overhead Water Tank Design by Working Stress - IS Method.pdf

BSides Seattle 2024 - Stopping Ethan Hunt From Taking Your Data.pptx

BSides Seattle 2024 - Stopping Ethan Hunt From Taking Your Data.pptx

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

VIP Call Girls Palanpur 7001035870 Whatsapp Number, 24/07 Booking

Call Girls In Bangalore ☎ 7737669865 🥵 Book Your One night Stand

Call Girls In Bangalore ☎ 7737669865 🥵 Book Your One night Stand

Material selection for different components

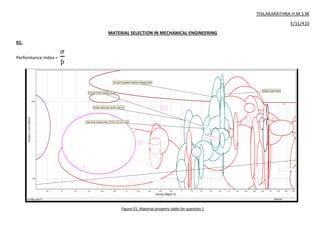

- 1. MATERIAL SELECTION IN MECHANICAL ENGINEERING 01. Performance index = 𝜎 ƥ Figure 01: Material property table for question 1

- 2. Table 01: Material properties for selected materials for question 1 Medium carbon steel is used to design because it had high performance index and low cost Material Strength (MPa) Density (Kg/m3 ) Performance index (m2 /s2 )x106 Cost SLR/Kg Remarks Wrought Precipitation Hardened Stainless Steel 1007.5 7.8 129.17 243.7 good corrosive resistence/expensive Nodular (spheroidal, ductile) Cast Iron 502.5 7.15 70.28 40.6 low cost Cast ferritic stainless steel, ASTM CC-50, low nickel 447.5 7.525 59.47 139.3 low ductility Medium Carbon Steel 1030 7.85 131.21 40.6 high strength/low cost Wrought Ferritic Stainless Steel 435 7.65 56.86 208.9 expensive

- 3. 02. Performance index = 𝜎 3 2 𝐸 Figure 02: Material property table for question 2

- 4. Table 02: Material properties for selected materials for question 2 Material Strength Youngs modulus Performance index Relative cost Polypropylene (PP) - 20% CaCO3 23 2000 0.055 75.4 Polytetrafluoroethylene (PTFE) GF1 (PTFE+25% Glass Fibre) 20 1400 0.064 986.5 Chloro TriFluoro Ethylene (CTFE) 23 1600 0.069 3597 Ethylene TetraFluoro Ethylene (ETFE) 26 1400 0.095 1972.5 Polypropylene (PP) - 20% Talc 28.5 2300 0.066 86.6 Polytetrafluoroethylene (PTFE) GF1 (PTFE+25% Glass Fibre) is selected for the designing though it had somewhat high cost because for safety proposes Material Strength (MPa) Young’s modulus (GPa) Performance index (MPa0.5 )x10-3 cost (SLR/Kg) Remarks Polypropylene (PP) - 20% CaCO3 23 2000 0.055 75.4 Use as coatings Polytetrafluoroethylene (PTFE) GF1 (PTFE+25% Glass Fibre) 20 1400 0.064 986.5 Use for non-stick applications Chloro TriFluoro Ethylene (CTFE) 23 1600 0.069 3597 High Chemical resistivity Ethylene TetraFluoro Ethylene (ETFE) 26 1400 0.095 1972.5 Use as film Polypropylene (PP) - 20% Talc 28.5 2300 0.066 86.6 Us for fiber reinforcement

- 5. 03. Performance indices M1 = 𝐾𝐼𝐶 M2 = 𝐾 𝐼𝐶 𝜎 𝑓 M3 = 𝐾𝐼𝐶 2 𝜎 𝑓 M4 = 𝜎𝑓

- 6. Figure 03: Material property chart for question 3 Table 03: Material properties for selected materials for question 3 Wrought Ferritic Stainless Steel is selected for the design because it had good PI and good thermal properties

- 7. Material Fracture thougness(PI1) Strength(PI4) Performance index 2 Performan Wrought Ferritic Stainless Steel 100.5 435 0.231 23.22 Low Carbon Steel 61.5 322.5 0.191 11.73 Cast Austenitic Stainless Steel 141.5 330.5 0.428 60.58 Wrought Precipitation Hardened Stainless Steel 102.5 1007.5 0.102 10.43 Cast Duplex Stainless Steel 100.5 510 0.197 19.80 Material Fracture toughness(PI1) (MPa.m0.5 ) Strength(PI4) (MPa) Performance index 2 (m0.5 ) Performance index 3 (MPa.m) Cost (SLR/Kg) Remarks Wrought Ferritic Stainless Steel 100.5 435 0.231 23.22 208.5 Good thermal properties Low Carbon Steel 61.5 322.5 0.191 11.73 40.5 Low PI Cast Austenitic Stainless Steel 141.5 330.5 0.428 60.58 324.9 Expensive Wrought Precipitation Hardened Stainless Steel 102.5 1007.5 0.102 10.43 243.5 Expensive/Corrosive resistance Cast Duplex Stainless Steel 100.5 510 0.197 19.80 231.5 Good corrosive resistance

- 9. Figure 04: Material property chart for question 4 Table 04: Material properties for selected materials for question 4 Material Thermal diffusivity Thermal conductivity Performance index Relative cost Medium Density Wood (Transverse) (0.45-0.85) 0.0000001245 0.1395 0.002529 493 Common Hard Brick 0.0000006231 0.9 0.000877 63 Cement 0.0000003228 0.85 0.000668 8 Normal Density Concrete 0.0000006678 1.65 0.000495 4.5 Granite 0.0000012773 2.85 0.000397 203 Common hard brick is selected for the design because it’s low cost and ,thermal conduction and easiness of manufacture Material Thermal diffusivity (m2 s) Thermal conductivity (W/m.k) Performance index (s0.5 /W.k) cost (SLR/KG) Remarks Medium Density Wood (Transverse) (0.45-0.85) 0.0000001245 0.1395 0.002529 493 Flammable/Expensive Common Hard Brick 0.0000006231 0.9 0.000877 63 Low thermal conductivity Cement 0.0000003228 0.85 0.000668 8 High thermal expansion Normal Density Concrete 0.0000006678 1.65 0.000495 4.5 High thermal expansion Granite 0.0000012773 2.85 0.000397 203 Expensive

- 10. 05.

- 11. Performance index = σ2 E Figure 05: Material property chart for question 5 Table 05: Material properties for selected materials for question5

- 12. Material Strength Youngs modulus Performance index Relative cost Wrought Ferritic Stainless Steel 435 200 0.946 208.9 Nodular Graphite Cast Iron 205 117.5 0.358 59 Blackheart Malleable Cast Iron 224.5 170 0.296 43.1 Nodular (spheroidal, ductile) Cast Iron 502.5 172.5 1.464 40.6 Cast Ferritic Stainless Steel 430 200 0.925 139 Nodular (spheroidal, ductile) Cast Iron is selected for the design because it had good PI and low cost. Material Strength (MPa) Young’s modulus (GPa) Performance index (MPa) Cost (SLR/Kg) Remarks Wrought Ferritic Stainless Steel 435 200 0.946 208.9 Chemical and corrosive resistance Nodular Graphite Cast Iron 205 117.5 0.358 59 use as gas manifolds Blackheart Malleable Cast Iron 224.5 170 0.296 43.1 not good corrosive resistance Nodular (spheroidal, ductile) Cast Iron 502.5 172.5 1.464 40.6 Low cost/ high PI Cast Ferritic Stainless Steel 430 200 0.925 139 Excellent corrosive resistance

- 13. 6.1 Performance index = E 1 2 Cv,R Figure 06: Material property chart for question 6.1

- 14. Table 06: Material properties for selected materials for question6.1 Material Youngs Modulus Cost Performance index Remarks Low Alloy White Cast Iron 185 34.8 0.3908 Good abration resis Wrought Aluminium Alloy 75 168 0.0515 Light weight Low Carbon Steel 210 40.5 0.3578 Used in engineering applications Wrought Ferritic Stainless Steel 200 208.5 0.0678 Expensive Cast ferritic stainless steel, ASTM CC-50, low nickel 200 139 0.1017 Low nickle content Low Carbon steel is selected for design because of its High young’s modulus and low cost. Material Young’s Modulus (GPa) Cost (SLR/Kg) Performance index (GPa.Kg/SLR) Remarks Low Alloy White Cast Iron 185 34.8 0.3908 Good abrasion resistance Wrought Aluminum Alloy 75 168 0.0515 Light weight Low Carbon Steel 210 40.5 0.3578 Used in engineering applications Wrought Ferritic Stainless Steel 200 208.5 0.0678 Expensive Cast ferritic stainless steel, ASTM CC-50, low nickel 200 139 0.1017 Low nickel content

- 15. 6.2

- 16. Performance index = 𝜎 𝑓 2 3 𝐶 𝑉,𝑅 Figure 07: Material property chart for question 6.2 Table 07: Material properties for selected materials for question6.2

- 17. Material Strength Cost Performance index Remarks Low Alloy White Cast Iron 345 34.8 1.4135 Good abration re Wrought Aluminium Alloy 270 168 0.2487 Light weight Low Carbon Steel 322.5 40.5 1.1612 Used in engineer applications Wrought Ferritic Stainless Steel 435 208.5 0.2754 Low PI Cast ferritic stainless steel, ASTM CC-50, low nickel 447.5 139 0.4209 Low nickle conte Low Carbon steel is selected for the design because it had high PI and low cost 6.3 According to the results in 6.1 and 6.2 Low Carbon steel is suitable for low cost, stiff and strong beam Abbreviation Material Strength Cost Performance index Remarks Low Alloy White Cast Iron 345 34.8 1.4135 Good abrasion resistance Wrought Aluminum Alloy 270 168 0.2487 Light weight Low Carbon Steel 322.5 40.5 1.1612 Used in engineering applications Wrought Ferritic Stainless Steel 435 208.5 0.2754 Low PI Cast ferritic stainless steel, ASTM CC-50, low nickel 447.5 139 0.4209 Low nickel content

- 18. SLR – Sri Lankan rupees