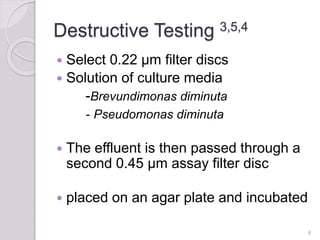

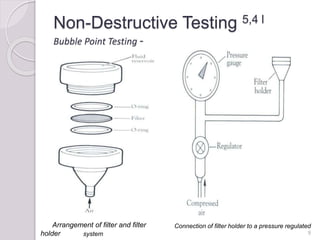

The document discusses the validation of membrane filters within pharmaceutical practices, emphasizing its importance for good manufacturing practices and product consistency. It outlines the responsibilities of drug manufacturers and quality assurance teams in ensuring filters meet specific validation criteria, including both destructive and non-destructive testing methods. The conclusion highlights that filter validation is essential not just for regulatory compliance but also for effective business operations.

![1

Validation of Membrane Filter

Mr. Sagar Kishor Savale

[Department of Pharmaceutics]

avengersagar16@gmail.com

2015-2016

Department of Pharmacy (Pharmaceutics) | Sagar savale](https://image.slidesharecdn.com/validationofmembranefilter-160530064438/75/Validation-of-membrane-filter-1-2048.jpg)