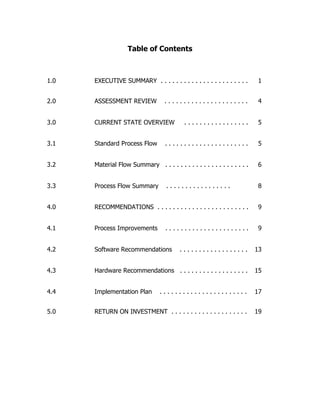

The document provides an assessment and recommendations for implementing a bar code system at ABC Company. It analyzes the company's current processes, identifies areas for improvement, and outlines a phased implementation strategy. Key recommendations include better utilizing their existing manufacturing software, improving business processes, implementing data collection (bar coding), and automating material and information flows to increase efficiency. The assessment found opportunities to reduce manual tasks, track inventory more accurately, and comply with customer requirements.