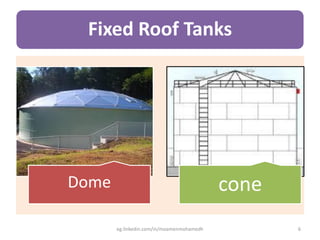

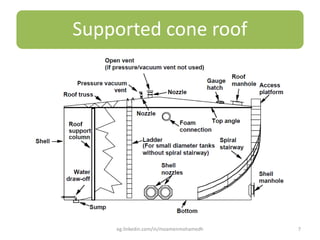

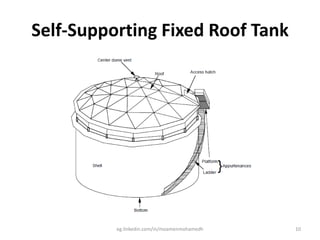

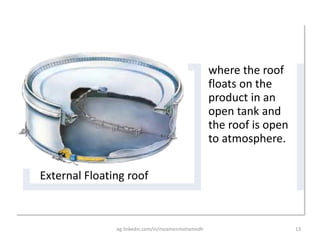

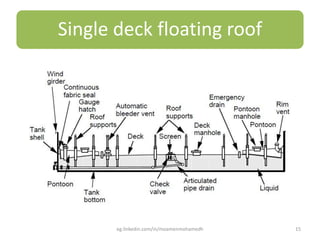

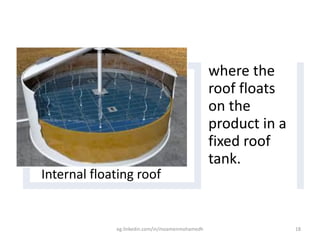

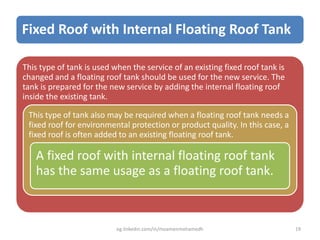

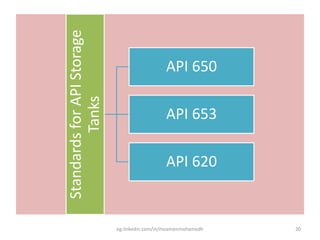

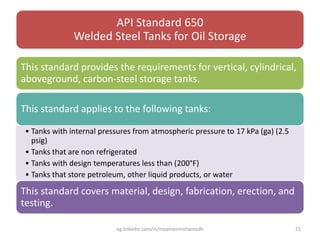

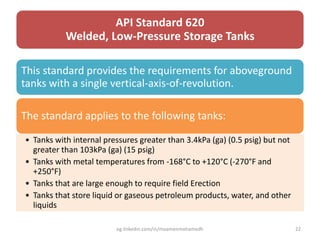

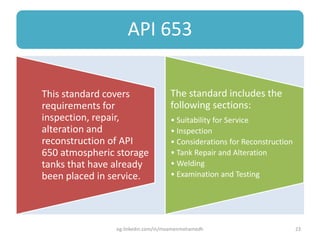

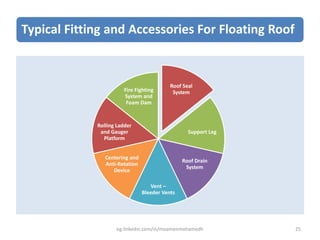

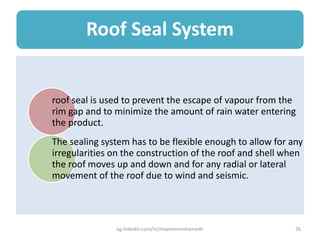

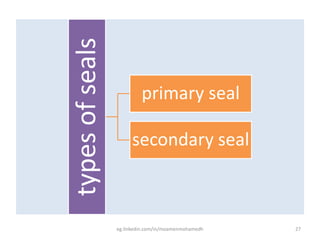

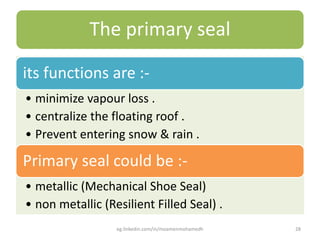

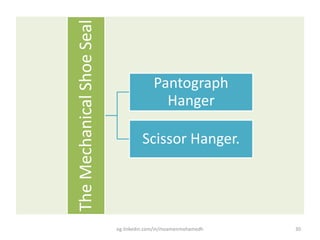

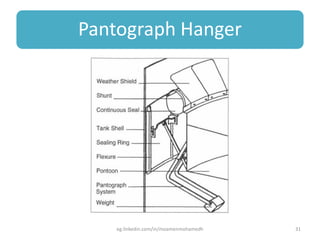

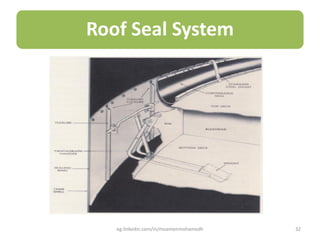

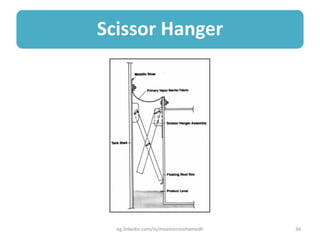

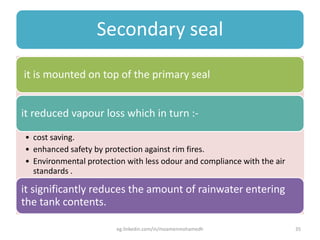

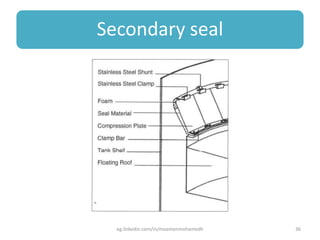

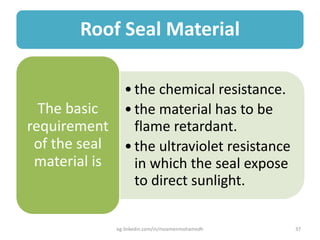

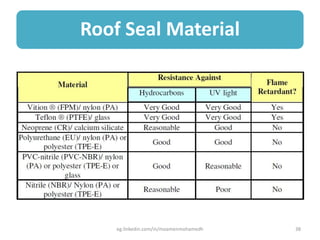

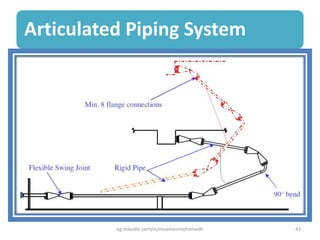

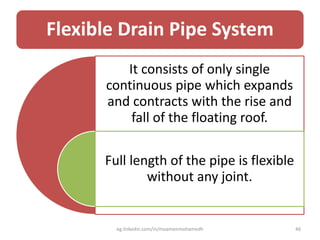

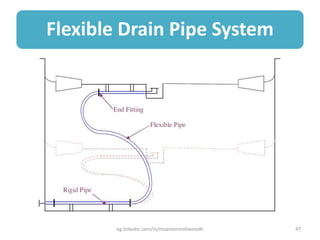

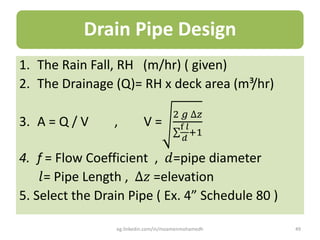

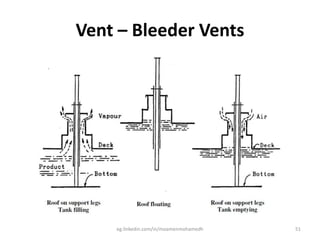

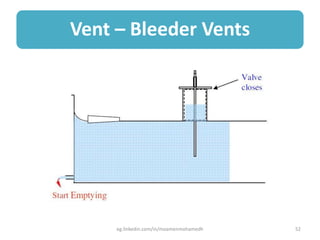

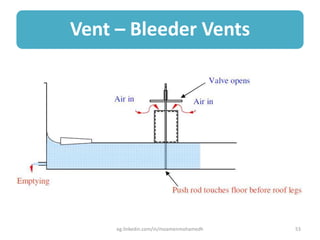

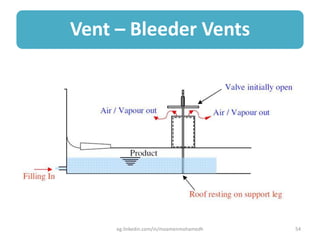

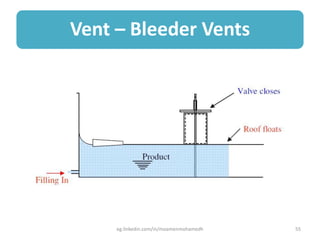

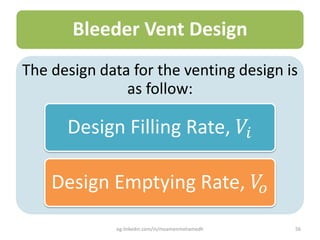

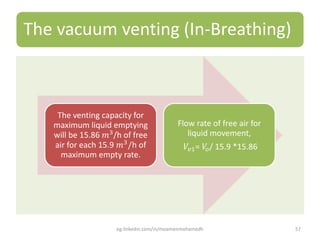

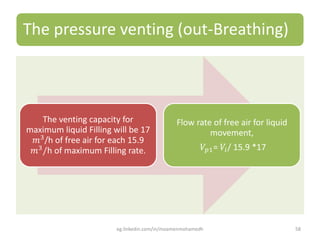

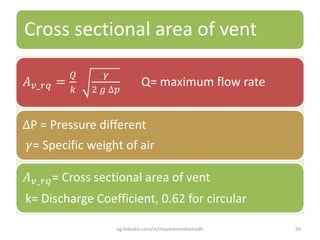

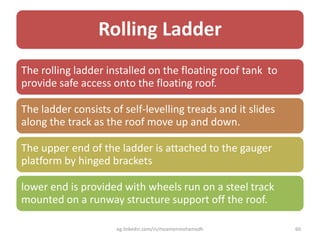

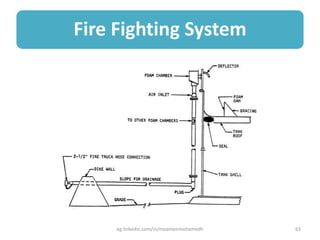

The document discusses different types of storage tanks including open top tanks, fixed roof tanks, and floating roof tanks. It provides details on supported cone roof tanks, self-supporting fixed roof tanks, single deck and double deck floating roof tanks, and internal floating roof tanks. Key parts and accessories for floating roof tanks are described such as the roof seal system, support legs, roof drain systems, and vents. Standards for storage tanks like API 650 and 653 are also mentioned.