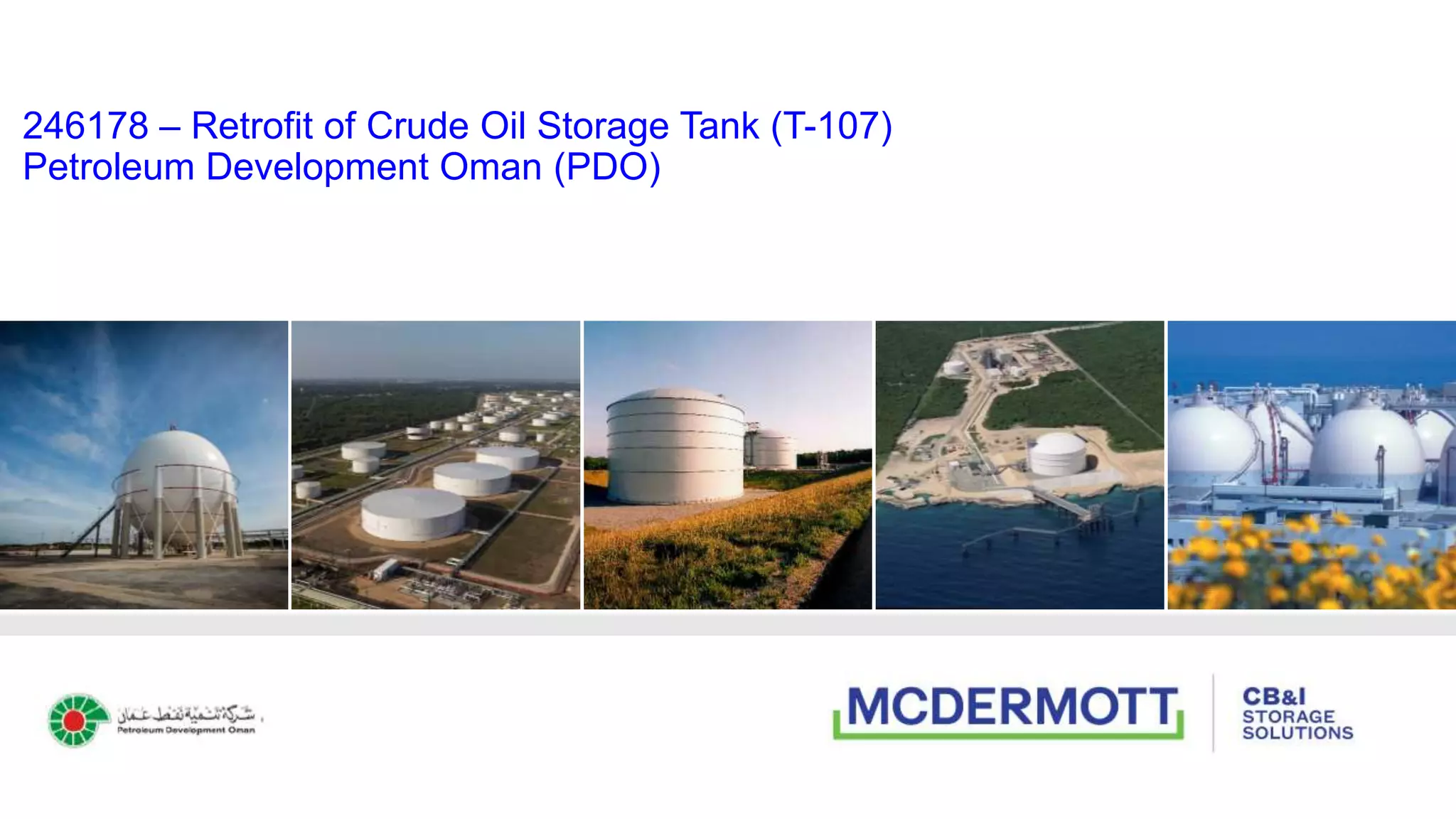

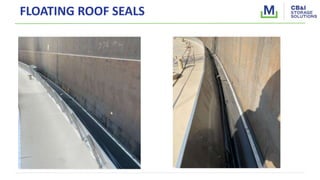

This document discusses the retrofit of the crude oil storage tank T-107 at Petroleum Development Oman. It addresses questions about the roof support system, emergency drain system, floating roof seals, vents, and other components. The roof support uses a locking sleeve assembly to support the roof in both operating and maintenance positions without damaging the lining. The emergency drains are positioned above the maximum water level and drain directly to the stored product. The number and size of drains are sufficient to drain rainfall at the specified design rate. The floating roof seals are maintenance-free under normal operating conditions.