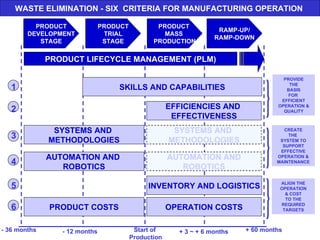

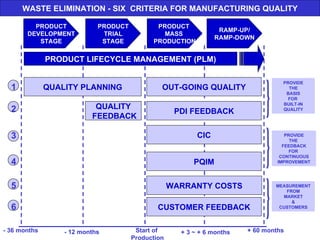

The document outlines a waste elimination program for a manufacturing operation with six key criteria across three stages: product development, product trial, and mass production. The criteria are skills and capabilities, efficiencies and effectiveness, systems and methodologies, inventory and logistics, operation and product costs, and automation and robotics. The goals of the criteria are to provide the basis for efficient and quality operations, create supportive systems, and align operations and costs with targets throughout the product lifecycle.