Laser shock peening presentation

- 1. LASER SHOCK PEENING KOTA MANISH KUMAR (1602-17-745-002)

- 2. CONTENTS Introduction Literature Review Experimental Setup Working Process What are residual stresses Incremental hole drilling method Factors influencing residual stresses Advantages Conclusion References

- 3. INTRODUCTION Peening is the process of working a metals‘ s surface to improve its material properties It is a cold working process. Mechanical working processes 1. Hammers 2. Shots 3. Laser

- 4. WHAT IS LASER PEENING? Laser peening is a surface enhancement method for extending the life of metal components Laser peening improves fatigue life residual stresses generated by LSP typically extend 5to 10 times deeper than those produced by shot peening. longer service lifetimes

- 5. RESIDUAL STRESS ANALYSIS ON TITANIUM ALLOY TC4 BY LASER SHOCK PEENING This test was performed by jun hong li ,he is from china. He is done LSP test on TC4 material the residual stresses using x-ray stress analyser Results indicates that there was large residual stresses are induced on the surface of material.

- 6. PARAMETRIC STUDY ON SINGLE SHOT AND OVERLAPPING LASER SHOCK PEENING ON VARIOUS METALS VIA MODELLING AND EXPERIMENTS This paper is written by yunfeng cao and yung c.shin. this experiment performed on 4140 steel and TI- 6AL-4V materials These are underwater confinement process And he used 3-d finite element for analyse residual stresses in the materials

- 7. AN ANALYTICAL MODEL TO PREDICT RESIDUAL STRESS FIELD INDUCED BY LASER SHOCK PEENING This paper was published by yongxiang hu and zheqiang yao and jun hu He proposed a complete analytical model of LSP He used FEM to calculate residual stresses in the material

- 8. EXPERIMENTAL AND NUMERICAL INVESTIGATION OF RESIDUAL STRESSES IN LASER PEENED AA2198 This paper was published by s.keller,s.chupakhin, p.staron,e.maawad,n.kashaev Lsp is done on AA2198 material Experimental and numerical investigation are done using different investigating models Using hole drilling method and x-ray diffraction test

- 9. FINITE ELEMENT ANALYSIS OF VARIATION IN RESIDUAL STRESS DISTRIBUTION IN LASER SHOCK PEENING OF STEELS This paper was published rohit voothaluru and c.Richard liu gary j.cheng This experiment was done on 1053STEEL & 52100 AISI STEELS By using ansys software he compared residual stresses of 1053 STEEL and 52100 AISI STEELS

- 11. EXPERIMENTAL DETAILS Laser characteristics 1. Neodymium glass (Nd) laser (1054 nm wavelength) 2. 0.6 - 5 J energy per pulse 3. 1 - 3mm spot diameter 4. 2.78- 25GW/cm2 power density Opaque used 1. Paint 2. Tape Coolant used 1. water

- 12. • Specimen used 1. AA2198-T3, AA2198-T5 2. Specimen thickness : 3.2 mm • Base layer used: 1. Steel plate 2. Air

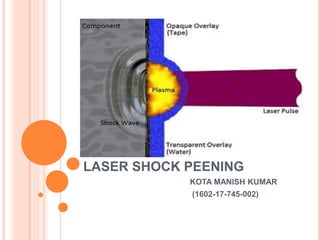

- 13. •PROCEDURE A high-energy, short-duration laser pulse produces a rapidly expanding plasma burst on the part surface The rapid rise of pressure generates a powerful compressive shockwave that propagates into the material.

- 14. TYPICAL LSP PROCESSING PARAMETERS FROM THE LITERATURE USED FOR DIFFERENT MATERIALS WITH CONCLUDING REMARKS.

- 15. WHAT ARE RESIDUAL STRESSES? Residual stresses are stresses that remain in a solid material after the original cause of the stresses has been removed Residual stress may be desirable or undesirable Undesirable residual stresses cause premature failures

- 16. WHY ARE RESIDUAL STRESSES BENEFICIAL? When a component is enhanced with compressive residual stresses, it can withstand greater tensile forces before cracking and failure occur. buffer against tensile strain, deeper compressive stresses inhibit crack initiation

- 17. METHODS TO FIND RESIDUAL STRESSES Nano-indentation, X-ray diffraction, metallographic microscope, SEM, TEM Incremental hole drilling method Fem

- 18. INCREMENTAL HOLE DRILLING METHOD Residual stresses were determined by the measurement system Prism from Stress-tech by 1. electronic speckle pattern interferometry (ESPI) or Strain gauges. 1. Drilling a hole incrementally. 2. Measurement of the surface deformation after each increment using ESPI or Strain gauges 3. Calculation of the residual stresses from surface deformations(Integral method)

- 19. ESPI SETUP

- 21. FACTORS INFLUENCING RESIDUAL STRESSES DURING EXPERIMENT Temper condition Focal size Laser power density Base layer

- 22. TEMPER CONDITION

- 23. FOCAL SIZE • Low focus size 1. high overlapping stresses 2. spherical wavefront • High focus size 1. high depth of penetration 2. linear wave front Laser power density 1. Higher power density leads to high pressure pulse irrespective of pulse energy

- 25. Influence of base layer Base layer is placed at the back of the work piece as a support. This will reflect back the wave into material to increase residual stresses.

- 26. Influence of specimen thickness 1. Increase in the thickness the shock wave intensity decreases at the end of plate 2. Reflected shock wave intensity also decreases

- 27. X-RAY DIFFRACTIONS TEST The photon energy: 87.1 kev Wave length:0.1419 Aº Pixel size :200μm Beam is 1.5 mt from work-piece

- 28. HDM VS XRD METHOD

- 29. ADVANTAGES o increases the strength o high fatigue resistance o High wear properties o Low cold work

- 30. DIS-ADVANTAGES High capital cost Repeated coating Difficult to control process variables

- 31. APPLICATIONS Engine components Turbine, fan, and compressor blades Bulkheads, wing attachments, flight control mechanisms, wheels Brakes, landing gear Welded titanium and aluminum components for improved reliability Welded aging aircraft parts for improved reliability

- 32. CONCLUSION As the LSP power density increased, the residual compressive stresses on the surface were also increased. fatigue resistance of material would be greatly improved Laser shock processing can make high residual compressive stress on the surface and deep inside of the material. Compressive stresses decreased gradually with the depth increased,