metalurgy science

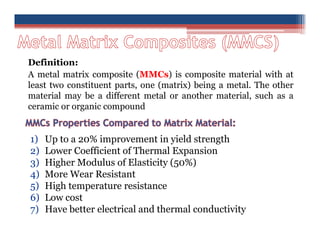

- 1. Definition: A metal matrix composite (MMCs) is composite material with at least two constituent parts, one (matrix) being a metal. The other material may be a different metal or another material, such as a ceramic or organic compound 1) Up to a 20% improvement in yield strength 2) Lower Coefficient of Thermal Expansion 3) Higher Modulus of Elasticity (50%) 4) More Wear Resistant 5) High temperature resistance 6) Low cost 7) Have better electrical and thermal conductivity

- 2. APPLICATIONS Automotive Engine components, braking systems (break discs and drums) Aerospace Undercarriage, guided weapons, satellites Marine Propellers, impellers, pressurized hulls, marine diesel components Sport Rackets, cycles and frames, motor racing, golf club Undercarriage Guided weapons

- 3. ELECTRONIC Substrates, thermal management, racking, power sources and storage MARINE Propellers, impellers, pressurized hulls, marine diesel components RAIL ENGINEERING Engine and braking components

- 4. Industrial Reciprocating and high speed machinery, precision equipment Military Gun barrel overwraps, missiles (aerofoils, fins and bodies), military diesel components Fins Gun barrel overwraps Aerofoils

- 5. The major advantages of Aluminum Matrix Composites (AMCs) 1) Increased specific strength (σ/ρ) 2) Increased specific stiffness (E/ρ) 3) Increased elevated temperature strength 4) Improved wear resistance 5) Lower density 6) Improved damping capabilities 7) Lower thermal expansion coefficients 8) Good corrosion resistance The principal matrix materials for MMCs are aluminum and its alloys. To a lesser extent, magnesium and titanium are also used, and for several specialized applications a copper, zinc or lead matrix may be employed.

- 6. A metal matrix reinforced by a second phase (continuous, and discontinues) Reinforcing phases: 1) Particles of ceramic (these MMCs are commonly called cermets), The most common reinforcing materials in this category are alumina and silicon carbide. 2) Fibers of various materials: other metals, ceramics, carbon, and boron.

- 7. Discontinuous MMCs can be isotropic, and can be worked with standard metalworking techniques, such as extrusion, forging or rolling. MMCs with discontinuous reinforcements are usually less expensive to produce than continuous fiber reinforced MMCs,. They may be machined using conventional techniques, but commonly would need the use of polycrystalline diamond tooling (PCD). Discontinuous reinforcement uses "whiskers", short fibers, or particles.

- 8. Continuous reinforcement uses monofilament wires or fibers such as carbon fiber. Fibers are embedded into the matrix in a certain direction, the result is an anisotropic structure in which the alignment of the material affects its strength. Example: boron filament as reinforcement. Consequently, continuous fiber reinforced MMCs are generally accepted as offering the ultimate mechanical properties.

- 9. MMC with ceramic contained in a metallic matrix The ceramic often dominates the mixture, sometimes up to 96% by volume Bonding can be enhanced by slight improving the solubility between phases at elevated temperatures used in processing Cermets can be subdivided into (1) Cemented carbides – most common (2) Oxide- based cermets – less common Metal Matrix Ceramic Particles (high toughness, strength, machinability) (high strength, stiffness & thermal stability)

- 10. Cemented Carbides One or more carbide compounds bonded in a metallic matrix Common examples of cemented carbides are; Tungsten carbide (WC), Titanium carbide (TiC), and Chromium carbide (Cr3C2) Tantalum carbide (TaC) and others are less common

- 11. 100μm Microstructure of an Al-SiC Metal Matrix Composite

- 12. Applications of Cemented Carbides Tungsten carbide cermets: cutting tools are most common; other: wire drawing dies, rock drilling bits , dies for powder metallurgy, indenters for hardness testers Titanium carbide cermets: high temperature applications such as gas- turbine nozzle vanes, thermocouple protection tubes, torch tips, cutting tools for steels Chromium carbides cermets: valve liners, spray nozzles, bearing seal rings

- 14. 2. Solid-State Processes a) Diffusion Bonding b) Deformation processing c) Powder processing d) Sinter-forging 3. In Situ Processes 4. Spray-Forming Process 1.Liquid-State Processes a) Casting or liquid infiltration b) Squeeze casting or pressure infiltration

- 15. 1. Liquid-State Processes a) Casting or liquid infiltration Liquid-phase infiltration of MMCs has difficulties with wetting the ceramic reinforcement by the molten metal. Fiber coatings applied prior to infiltration, which improve wetting and allow control of interfacial reactions.

- 16. One liquid infiltration process involving particulate reinforcement, called the Duralcan process, has been quite successful. Ceramic particles and ingot-grade aluminum are mixed and melted. The melt is stirred slightly above the liquidus temperature (600−700°C). The solidified ingot may also undergo secondary processing by extrusion or rolling. The Duralcan process of making particulate composites by a liquid metal casting route involves the use of 8−12 μm particles.

- 17. b) Squeeze casting or pressure infiltration Involves forcing a liquid metal into a fibrous or particulate preform. Squeeze casting or pressure casting are the most common manufacturing variants for MMCs..

- 18. Pressure is applied until solidification is completed. This method obviates the requirement of good wettability of the reinforcement by the molten metal. Advantages: 1) Minimal reaction between the reinforcement and molten metal because of the short processing time involved. 2) Such composites are also typically free from common casting defects such as porosity and shrinkage cavities.

- 19. 2. Solid-State Processes a) Diffusion Bonding (a) Apply metal foil and cut to shape, (b) lay up desired plies, (c) Vacuum encapsulate and heat to fabrication temperature, (d) Apply pressure and hold for consolidation cycle, and (e) Cool, remove, and clean part. (a) (b) (c) (e) (d)

- 20. This forced contact would lead to the atoms of individual metals to diffuse into the neighboring metal. Hence, the sheets will stick together quite tightly. Advantages: The ability to process a wide variety of metal matrices and control of fiber orientation and volume fraction. Disadvantages: Long processing time, high processing temperatures and pressures (which makes the process expensive), and a limitation on the complexity of shapes that can be produced.

- 21. (b) Deformation processing Can be used to deform the composite material. In metal−metal composites mechanical processing (extrusion, drawing, or rolling) of a ductile two-phase material causes the two phases to deform, causing one of the phases to elongate and become fibrous in nature within the other phase. Roll bonding is a common technique used to produce a laminated composite consisting of different metals in layered form. Such composites are called sheet laminated metal-matrix composites. Roll bonding and hot pressing have also been used to make laminates of Al sheets and discontinuously reinforced MMCs

- 22. Powder processing, hot pressing, and extrusion process for fabricating particulate or short fiber reinforced MMCs. (c) Powder processing

- 23. Powdered metal and dispersed metal or ceramic powder or discontinuous fibers are mixed. It involves cold pressing or hot pressing to fabricate primarily particle or whisker-reinforced MMCs. The matrix and the reinforcement powders are mixed to produce a homogeneous distribution The blending stage is followed by cold pressing . The cold pressed material is packaged in a closed container and degassed to remove any absorbed moisture from the particle surfaces. The material is hot pressed to produce composite and extruded. The rigid particles or fibers cause the matrix to be deformed significantly.

- 24. (d) Sinter-forging Sinter-forging technique for producing near-net shape, low cost MMCs A novel and low cost deformation processing technique.

- 25. A powder mixture of reinforcement and matrix is cold compacted, sintered, and forged. The main advantage of this technique is that forging is conducted to produce a near-net shape material, and machining operations and material waste are minimized. The low cost, sinter-forged composites have tensile and fatigue properties that are comparable to those of materials produced by extrusion.

- 26. 3. In Situ Processes It is a process in which the reinforcing phase is formed in the matrix as a result of precipitation from the melt during the cooling and solidification processes. Types of in-situ MMCs: – in situ MMC Particulate . 1 Particulate composite reinforced by in situ synthesized dispersed phase in form matrix Aluminum g. : e. of particles. ( ) 2 TiB reinforced by titanium boride ( matrix reinforced magnesium particles, Si particles). 2 by Mg

- 27. fiber - Short – reinforced in situ MMC fiber - Short . 2 composite reinforced by in situ synthesized dispersed phase in form of short fibers or whiskers (single crystals grown in form of short fibers). Examples: ) 2 TiB titanium boride ( reinforced by Titanium matrix - whiskers, ) 3 TiAl titanium aluminide ( reinforced by Aluminum matrix - whiskers. fiber - Long – reinforced in situ MMC fiber - Long . 3 composite reinforced by in situ synthesized dispersed phase in form of continuous fibers. Example: Nickel-aluminum (NiAl) matrix reinforced by long continuous fibers of Mo (NiAl-9Mo alloy).

- 28. Advantages of in situ Metal Matrix Composites: In situ synthesized particles and fibers are smaller than those in materials with separate fabrication of dispersed phase (ex-situ MMCs). Fine particles provide better strengthening effect; In situ fabrication provides more homogeneous distribution of the dispersed phase particles; Bonding (adhesion) between the particles of in situ formed dispersed phase and the matrix is better than in ex-situ MMCs; Equipment and technologies for in situ fabrication of MMCs are less expensive. Disadvantages of in situ Metal Matrix Composites: Choice of the dispersed phases is limited by thermodynamic ability of their precipitation in particular matrix; The size of dispersed phase particles is determined by solidification conditions;

- 29. 4. Spray-Forming of Particulate MMCs The spray-forming process A co-spray process, uses a spray gun to atomize a molten aluminum alloy matrix resulting in a fine solid powder, into which heated silicon carbide particles are injected

- 30. The spray process is generally automated and quite fast. The formation of reaction products is generally avoided because the time of flight of the composite particles is extremely short. Silicon carbide particles of an aspect ratio (length/diameter) between 3−4 and volume fractions up to 20% have been incorporated into aluminum alloys.