Production and operation management

- 1. Mr. Harsha C Mathad

- 2. Introduction, meaning & definition, Classification, Objectives and scope of production and operation management, Automation – Introduction, meaning, definition, need, types, advantages & disadvantages.

- 3. Plant Location - Introduction, meaning, definition, factors affecting location, theory and practices, cost factor in location. Plant layout – Meaning, principles, space requirement, different types of facilities, organization of physical facilities, building, sanitation, lighting, air conditioning and safety.

- 4. Introduction, meaning, definition, Purchasing selection of suppliers, Inventory management, materials handling, principles & practices, economic consideration, criteria for selection of materials handling equipment, standardization, codifications, simplification inventory control, techniques of inventory control, value analysis, value engineering, human engineering, inter relationship of plant layout and material handlings.

- 5. Objectives and concepts, capacity planning, corresponding production planning, controlling, scheduling routing, quality control, statistical quality control, quality management, control charts and operating, characteristics curves, acceptance sampling procedures, quality circle, meaning of ISO and TQM.

- 6. Introduction, meaning, objectives, types of maintenance, breakdown, space planning & control, preventive practice, relative advantage maintenance scheduling, equipment reliability and modern scientific maintenance methods, waste management, scope & surplus disposal, salvage & recovery.

- 7. Production is the process by which raw materials and other inputs are converted into finished products.

- 10. Operations management is a systematic approach to addressing issues and resolving issues in the transformation process that converts inputs into useful revenue generating outputs.

- 11. Production and operations management concern with the conversion of inputs into outputs, using physical resources, so as to provide the desired utilities to the customer while meeting the other organizational objectives of effectiveness, efficiency and adoptability.

- 12. • Maximum possible productivity with best quality, quantity and cost. • Maximum customer satisfaction through quality, reliability, cost and delivery time. • Minimum scrap/rework resulting in better product quality. • Minimum possible inventory levels (i.e., optimum inventory levels).

- 13. • Maximum utilization of all kinds of resources needed. • Minimum cash outflow and maximum employee satisfaction. • Maximum possible production (i.e., outputs) with higher operating efficiency. • Minimum production cycle(Lead time) time with protection of employees and environment. • Maximum possible profit or return on investment.

- 14. Production systems can be classified as Job Shop, Batch, Mass and Continuous Production systems. • Job shop production • Batch production • Mass production

- 16. Job shop production are characterized by manufacturing of one or few quantity of products designed and produced as per the specification of customers within prefixed time and cost. The distinguishing feature of this is low volume and high variety of products.

- 17. Advantages Following are the advantages of job shop production: 1. Because of general purpose machines and facilities variety of products can be produced. 2. Operators will become more skilled and competent, as each job gives them learning opportunities. 3. Full potential of operators can be utilized. 4. Opportunity exists for creative methods and innovative ideas. Limitations Following are the limitations of job shop production: 1. Higher cost due to frequent set up changes. 2. Higher level of inventory at all levels and hence higher inventory cost. 3. Production planning is complicated. 4. Larger space requirements.

- 18. Batch production is defined by American Production and Inventory Control Society (APICS) “as a form of manufacturing in which the job passes through the functional departments in lots or batches and each lot may have a different routing.” It is characterized by the manufacture of limited number of products produced at regular intervals and stocked awaiting sales.

- 19. Advantages Following are the advantages of batch production: 1. Better utilization of plant and machinery. 2. Promotes functional specialization. 3. Cost per unit is lower as compared to job order production. 4. Lower investment in plant and machinery. 5. Flexibility to accommodate and process number of products. 6. Job satisfaction exists for operators. Limitations Following are the limitations of batch production: 1. Material handling is complex because of irregular and longer flows. 2. Production planning and control is complex. 3. Work in process inventory is higher compared to continuous production. 4. Higher set up costs due to frequent changes in set up.

- 20. Manufacture of discrete parts or assemblies using a continuous process are called mass production. This production system is justified by very large volume of production. The machines are arranged in a line or product layout. Product and process standardization exists and all outputs follow the same path.

- 21. Advantages Following are the advantages of mass production: 1. Higher rate of production with reduced cycle time. 2. Higher capacity utilization due to line balancing. 3. Less skilled operators are required. 4. Low process inventory. 5. Manufacturing cost per unit is low. Limitations Following are the limitations of mass production: 1. Breakdown of one machine will stop an entire production line. 2. High investment in production facilities.

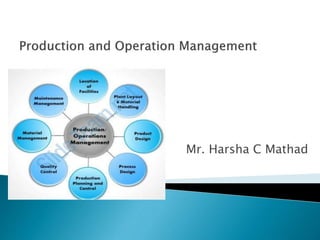

- 22. Location. Plant layouts and material handling. Product design. Process design. Production and planning control. Routing Scheduling Dispatching Quality control. Materials management. Maintenance management.

- 23. Automation means adopting technology with the collaboration of mechanical, electronic, and computer based systems to operate and control production.

- 24. 1. Fixed automation. 2. Programmable automation. 3. Flexible automation.

- 25. It is a system in which the sequence of processing (or assembly) operations is fixed by the equipment configuration. The operations in the sequence are usually simple.

- 26. In this the production equipment is designed with the capability to change the sequence of operations to accommodate different product configurations. The operation sequence is controlled by a program, which is a set of instructions coded so that the system can read and interpret them.

- 27. It is an extension of programmable automation. A flexible automated system is one that is capable of producing a variety of products (or parts) with virtually no time lost for changeovers from one product to the next.

- 28. • To Increasing productivity. • To Reducing cost of labour. • To over come labour shortages. • To increase Safety. • To Improve product quality. • To Reduced manufacturing lead time. • To Reduction of in-process inventory.

- 29. • It increases productivity and quality of the production. • It helps in reducing cost of labour and bring efficiency in production process. • It create safety in the production activity. • The growth of the automation industry will itself provide employment opportunities. This has been especially true in the computer industry, as the companies in this industry have grown (IBM, Digital Equipment Corp., Honeywell, etc.), new jobs have been created. • It increases the standard of living.

- 30. • There will be a reduction in the labour force, with resulting unemployment. • Automation will reduce purchasing power. As machines replace workers and these workers join the unemployment ranks, they will not receive the wages necessary to buy the products brought by automation.