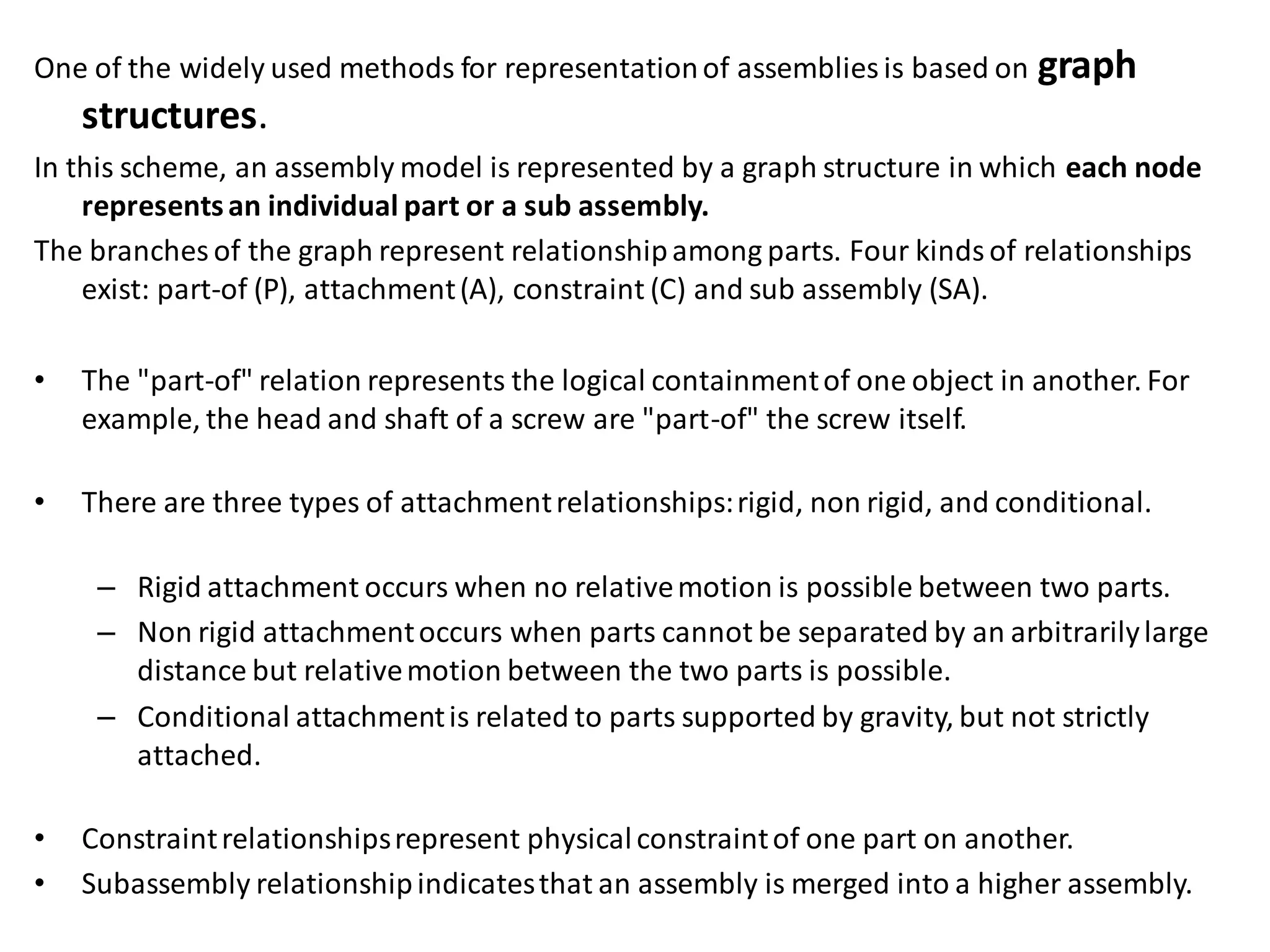

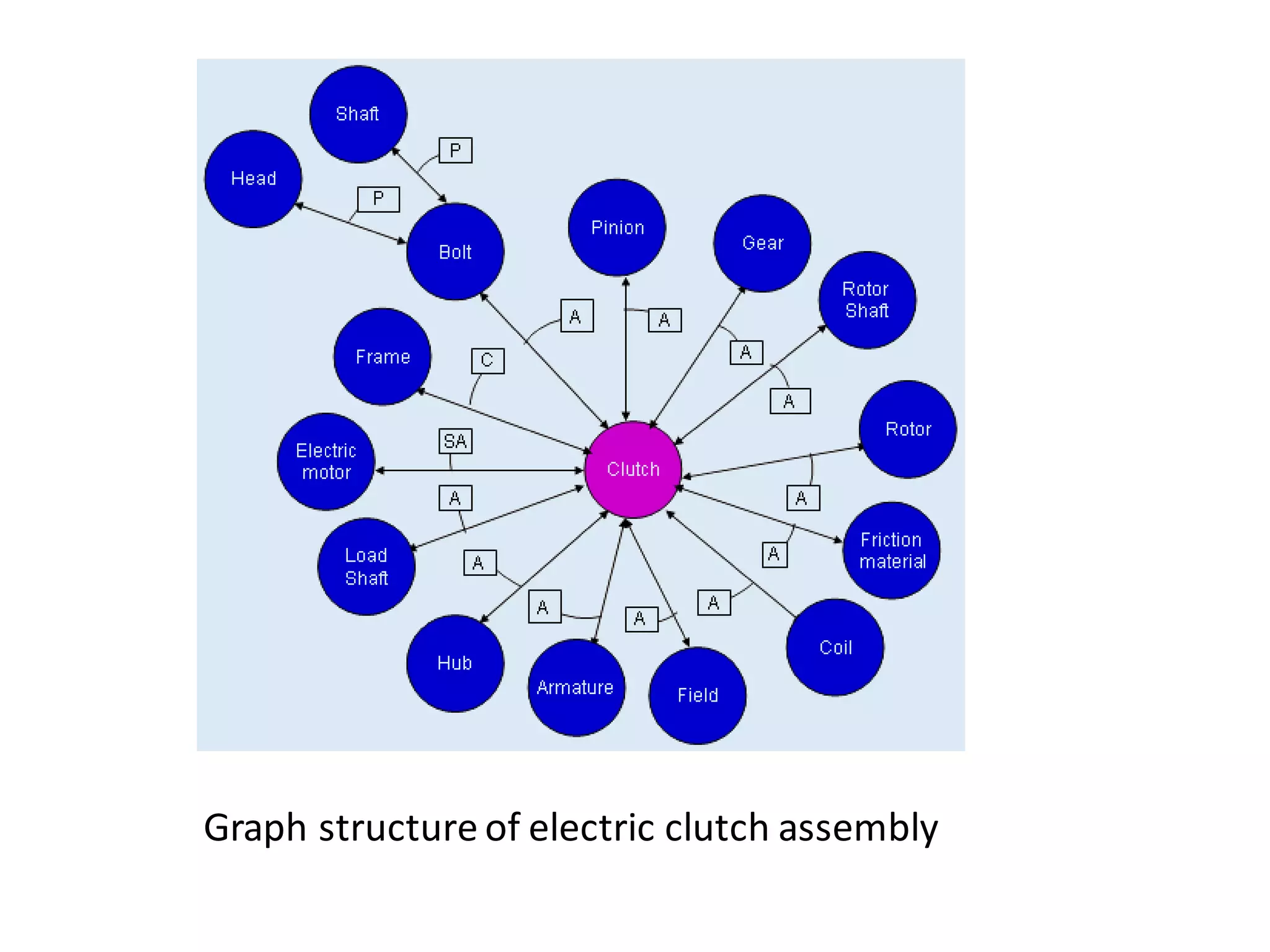

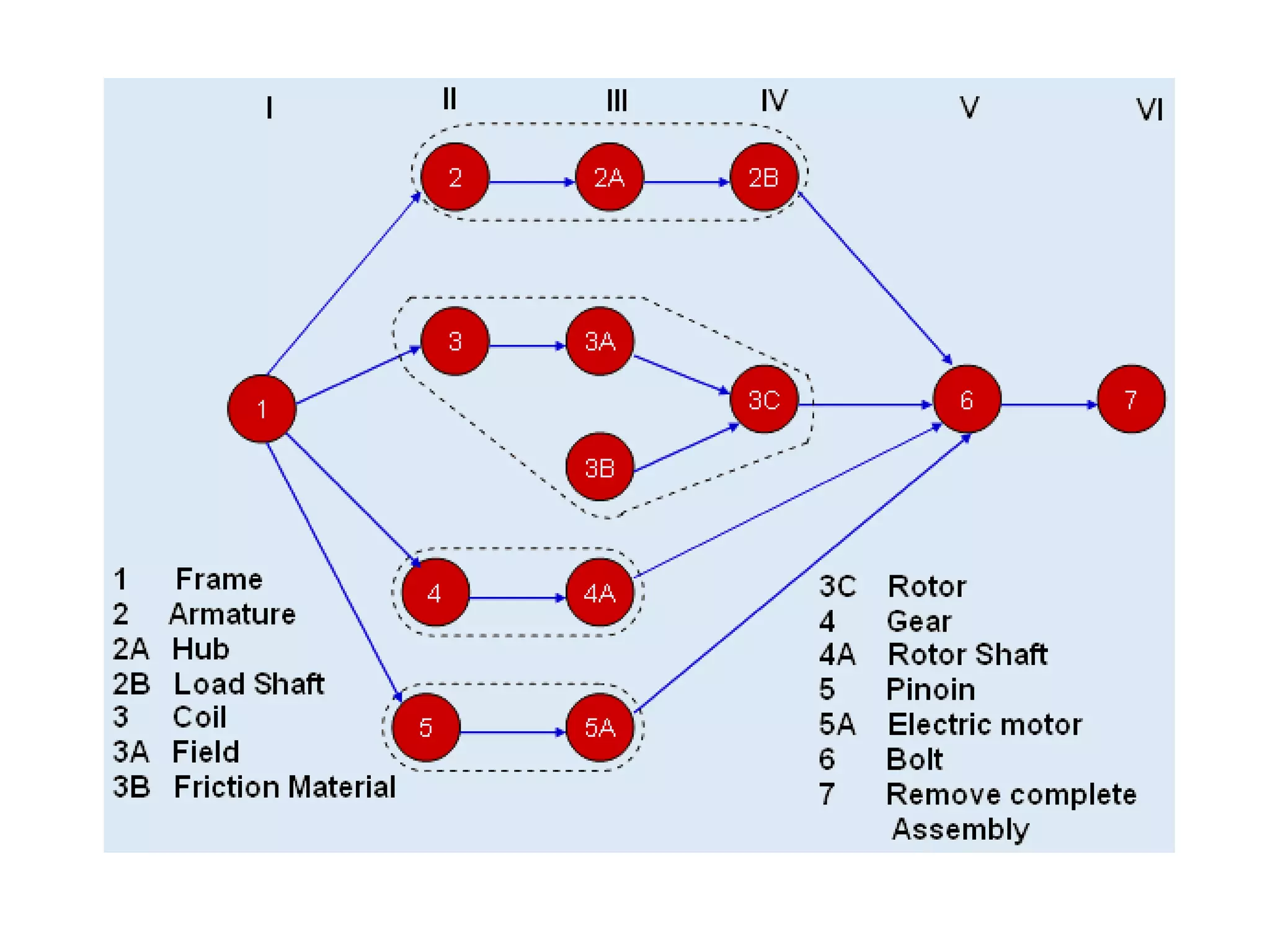

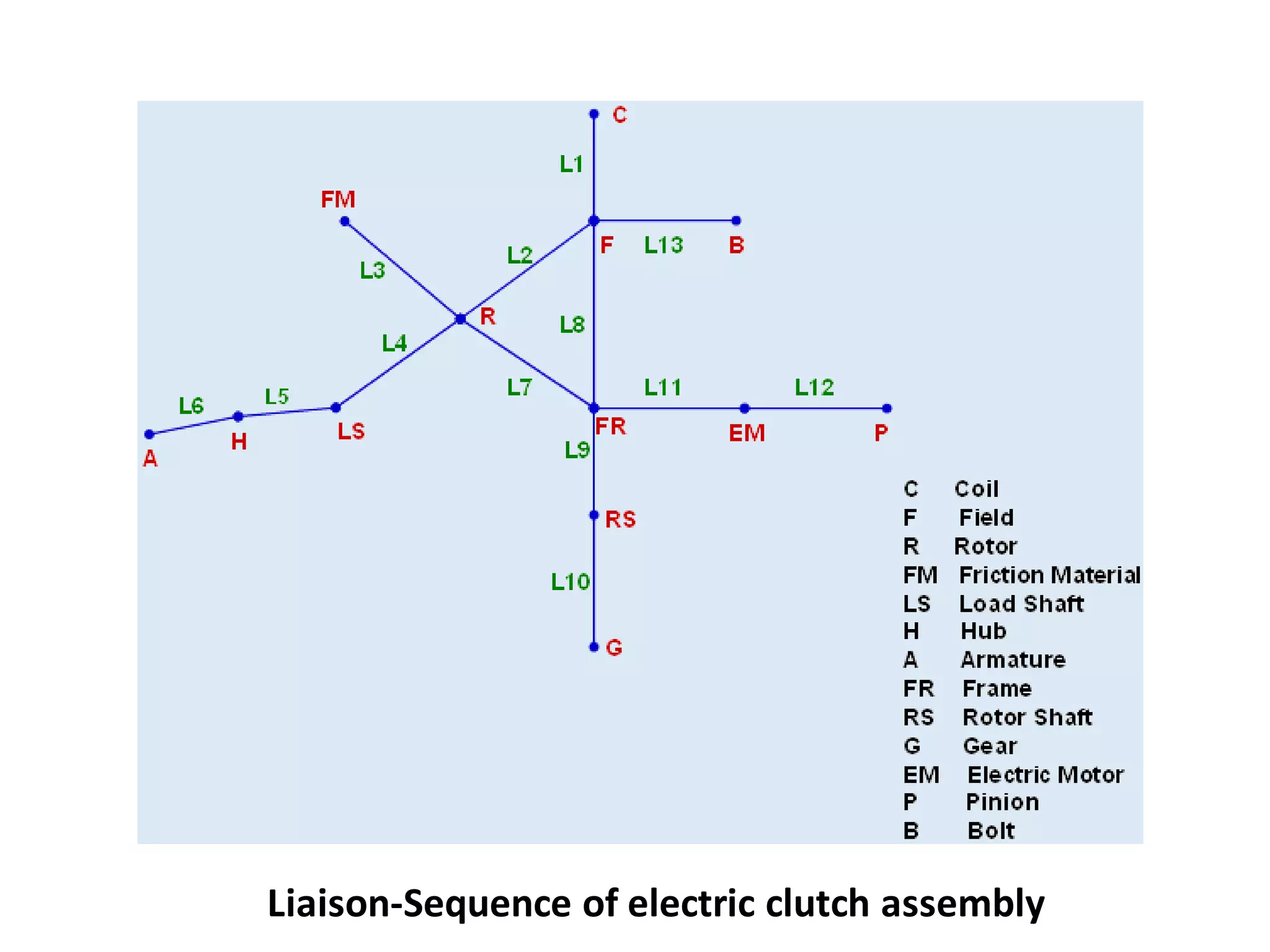

This document discusses assembly modeling concepts including:

- The differences between part and assembly modeling and common assembly modeling approaches like bottom-up and top-down.

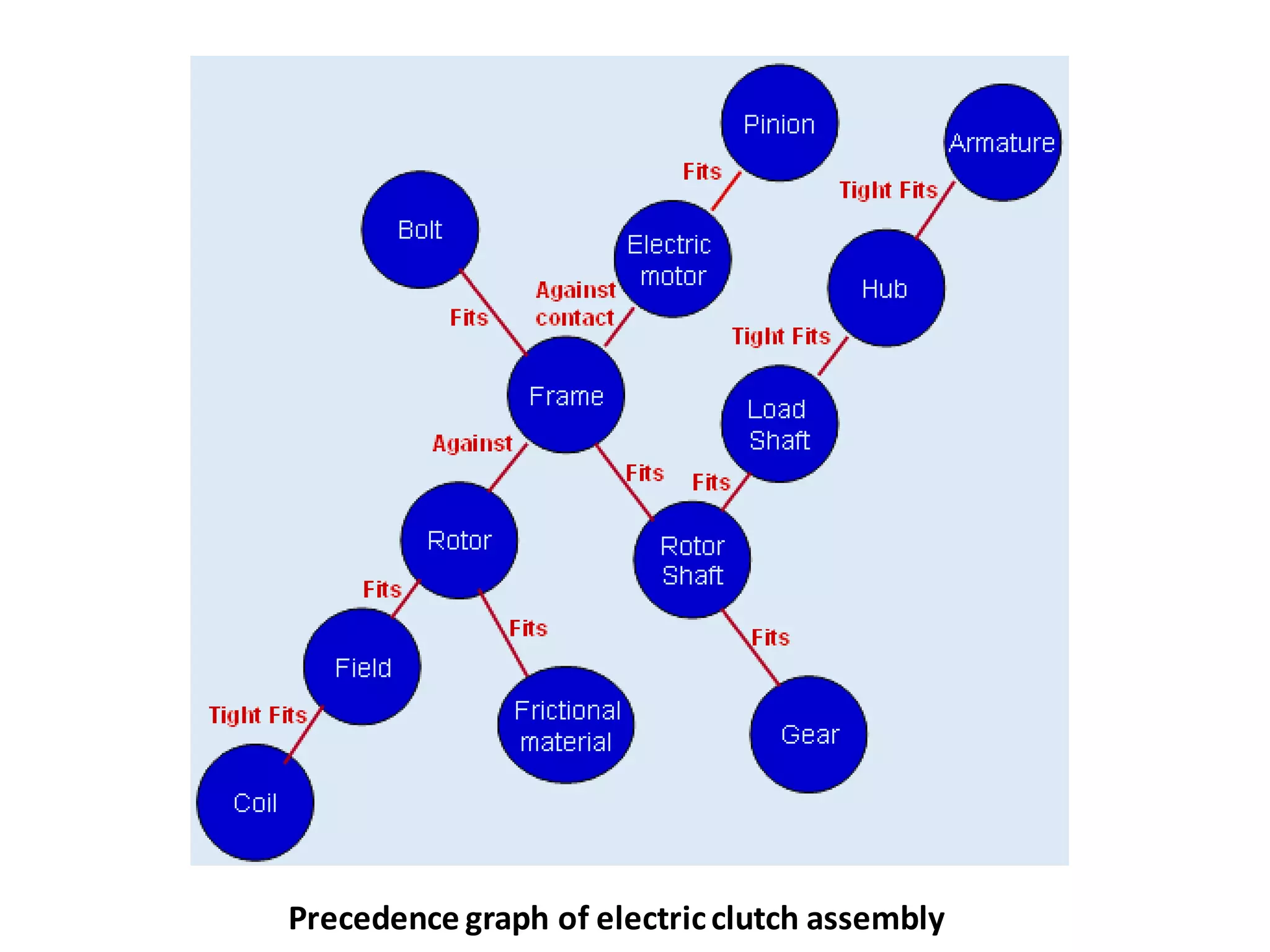

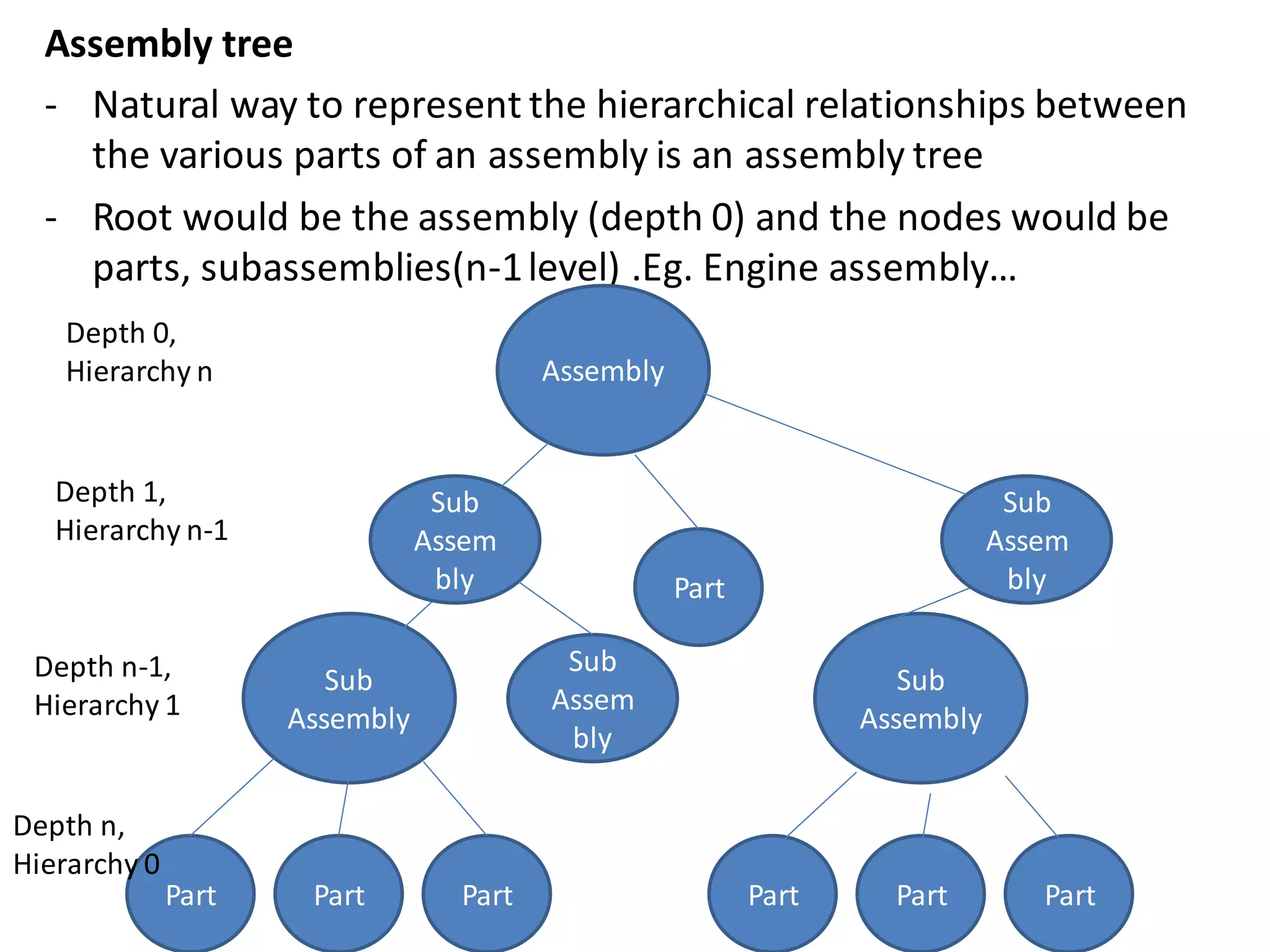

- Key aspects of assembly modeling like hierarchy, mating conditions, assembly trees, and managing large assemblies.

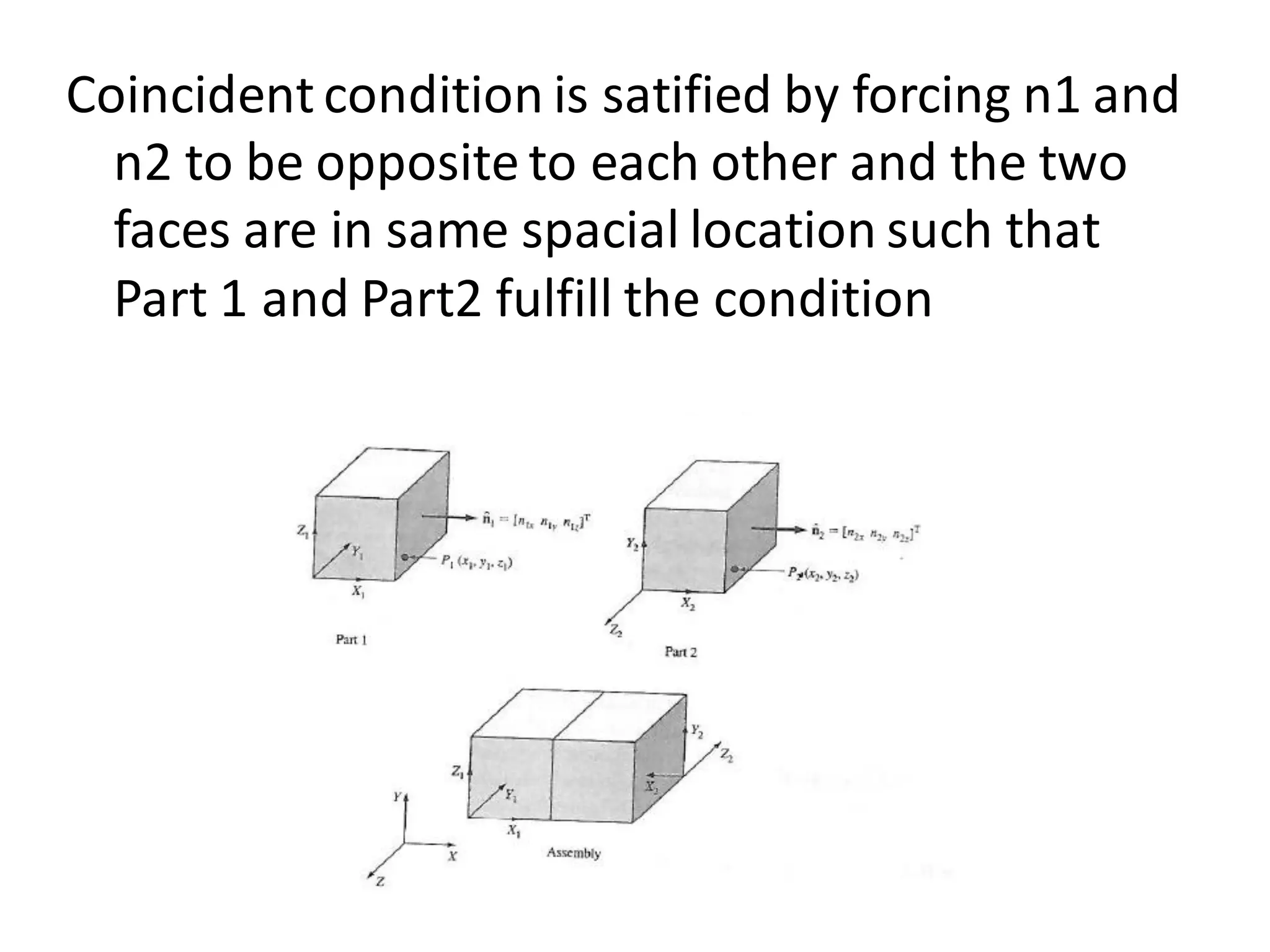

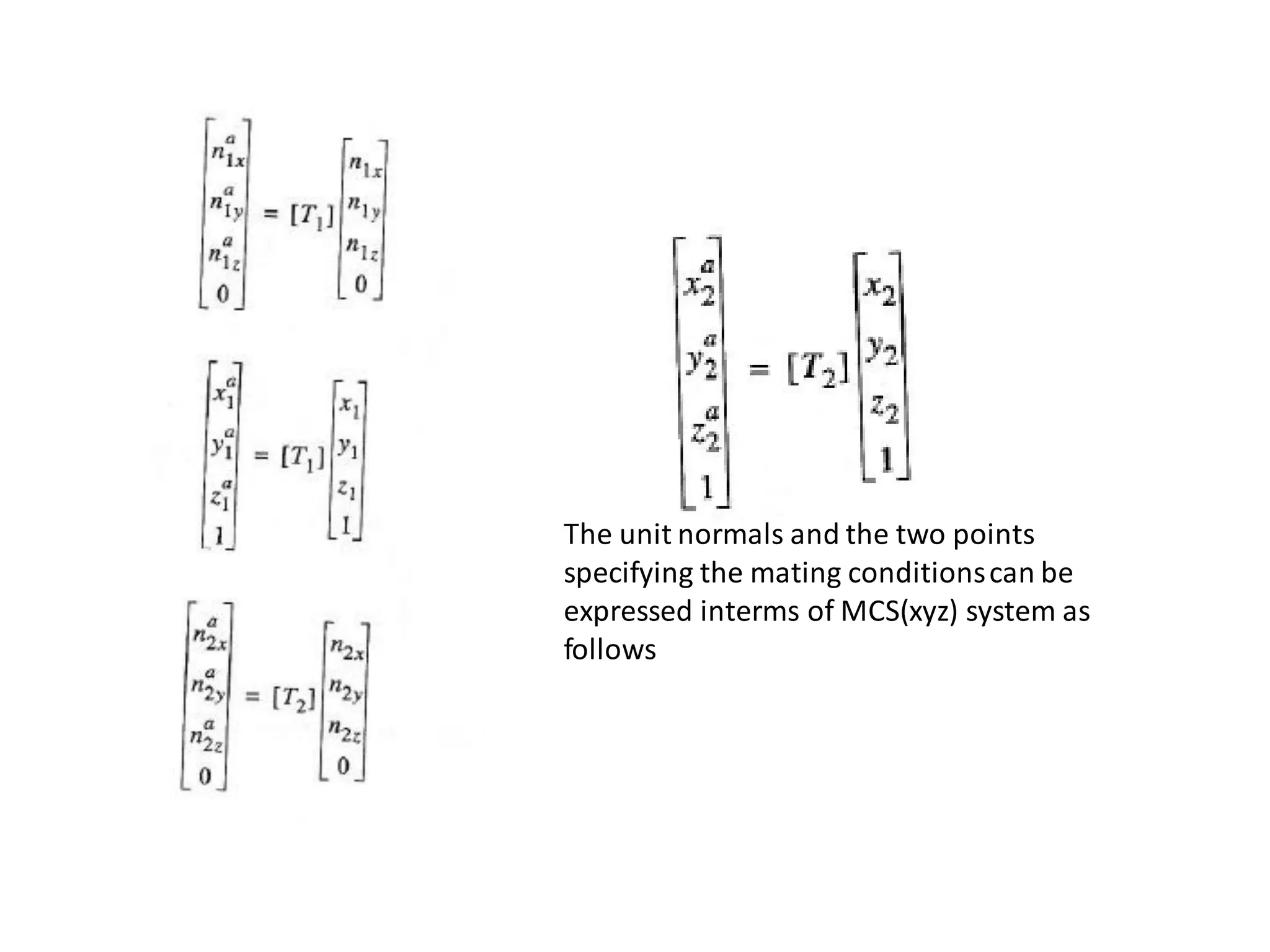

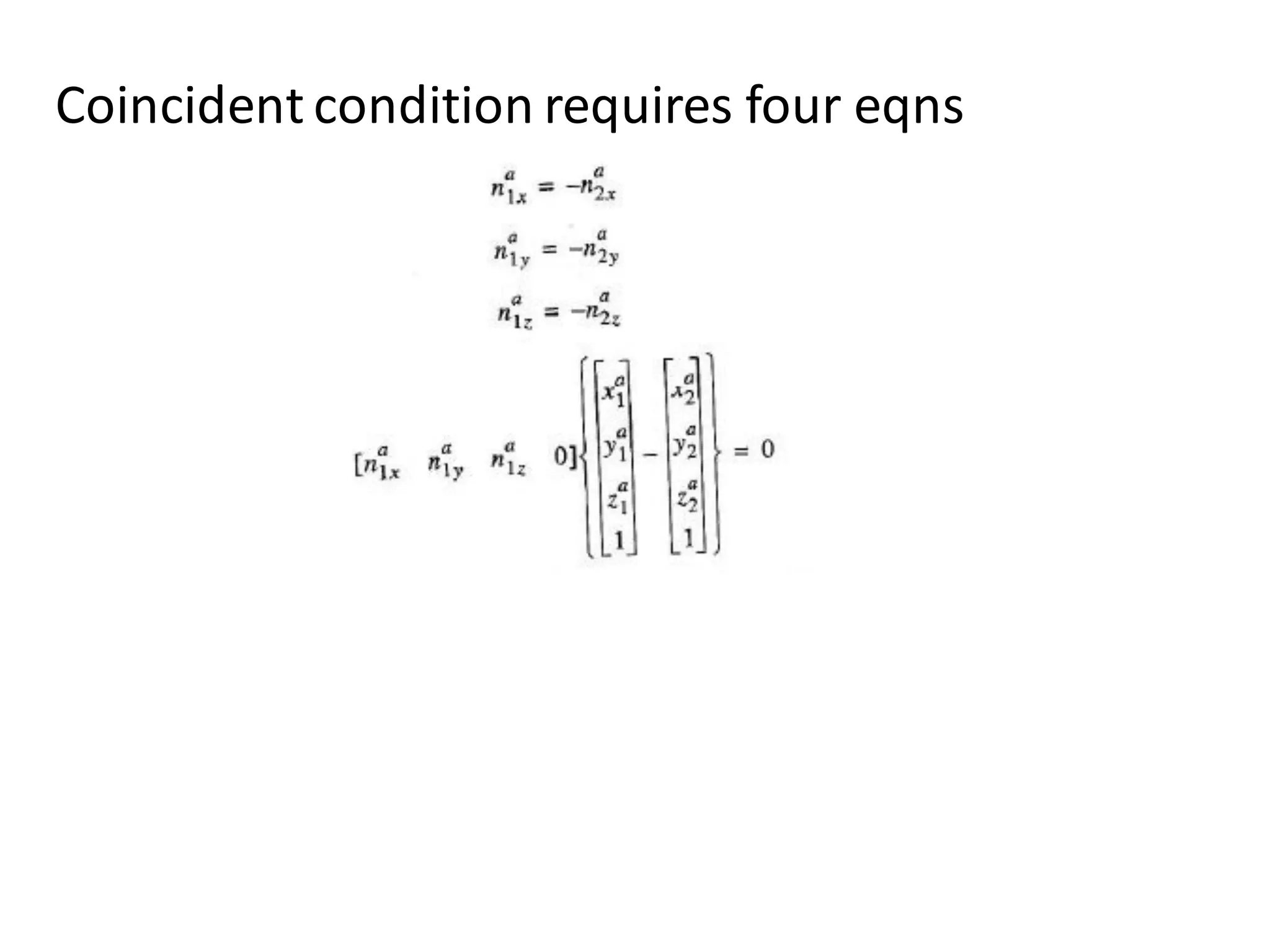

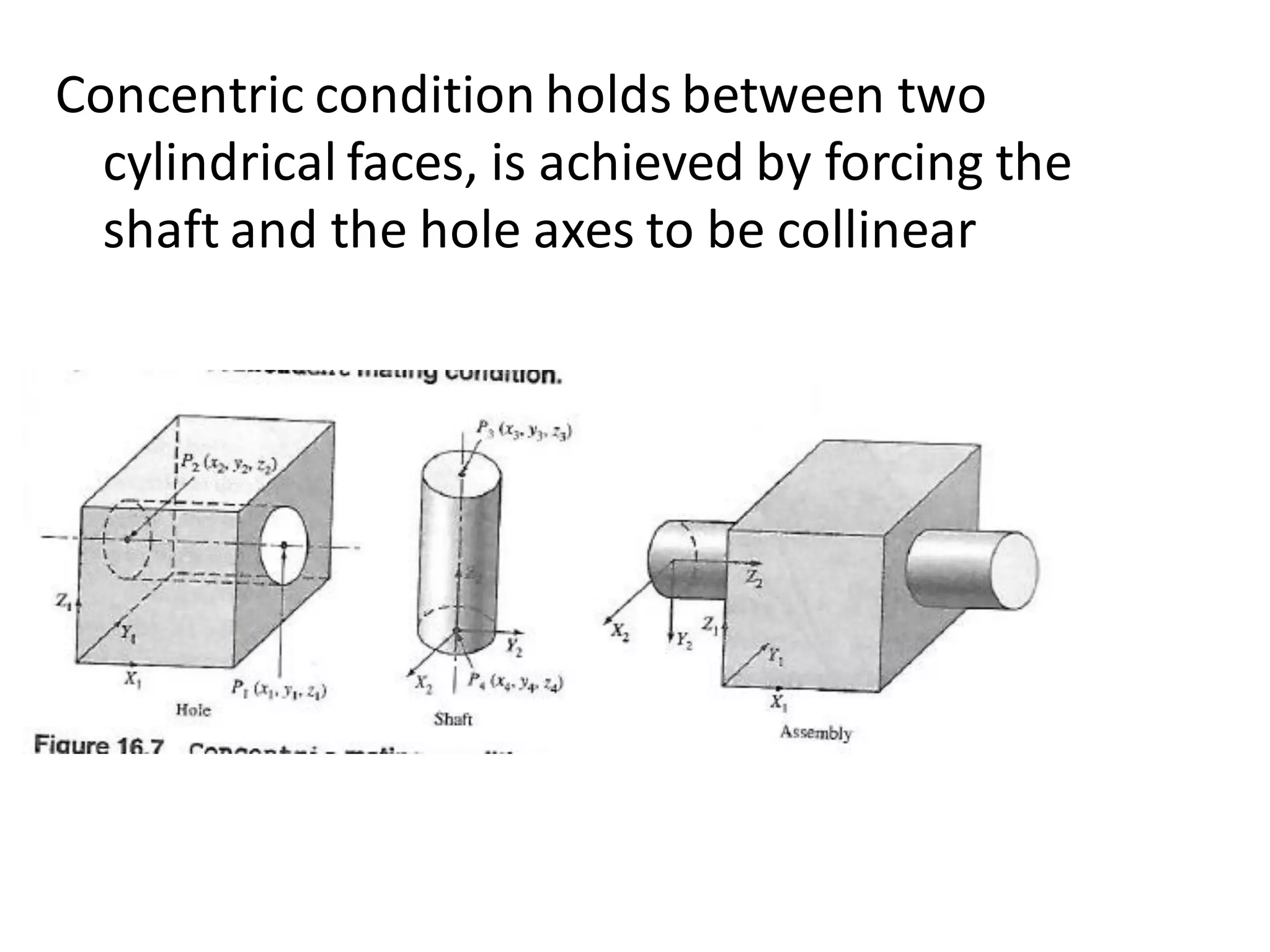

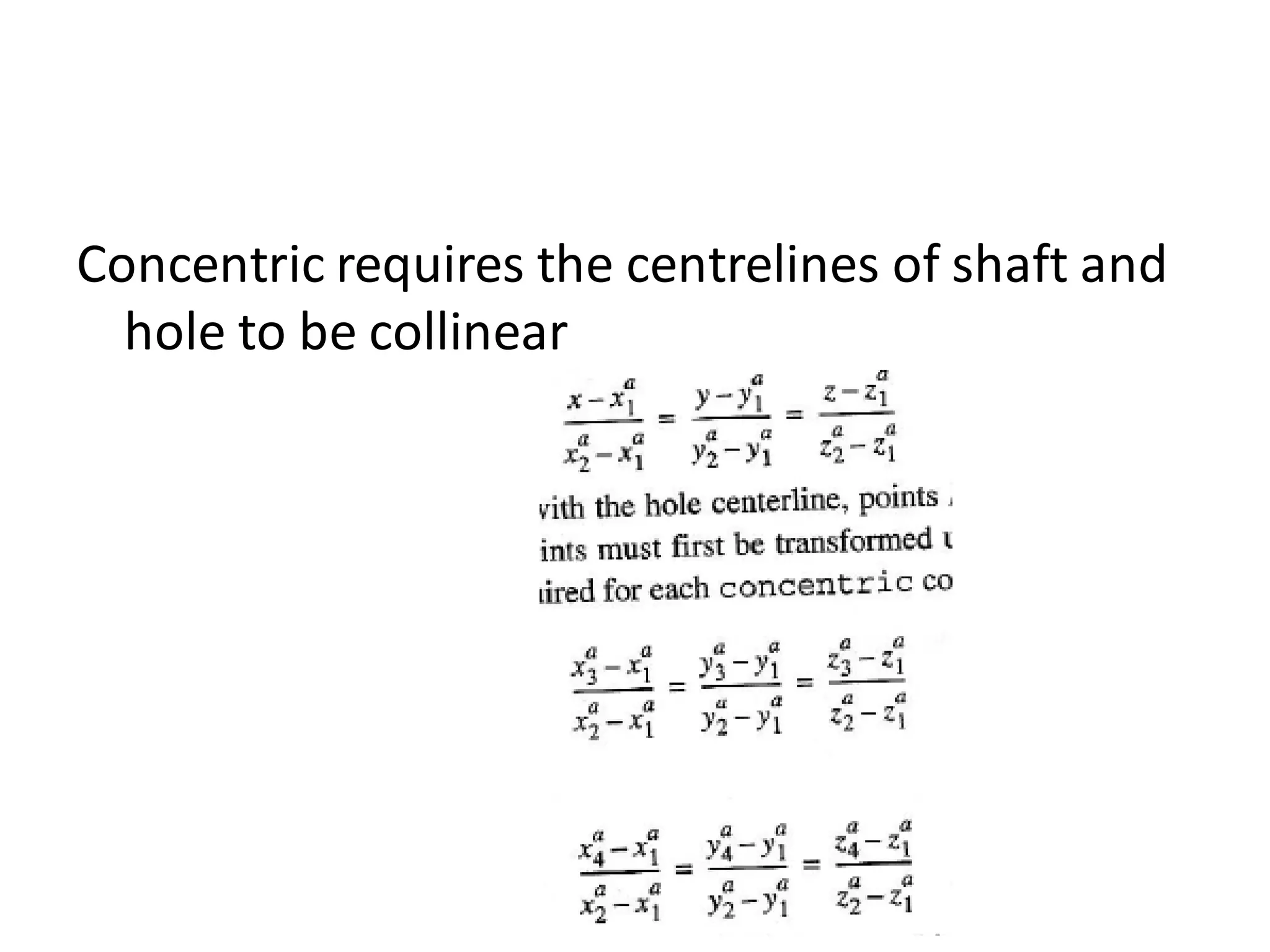

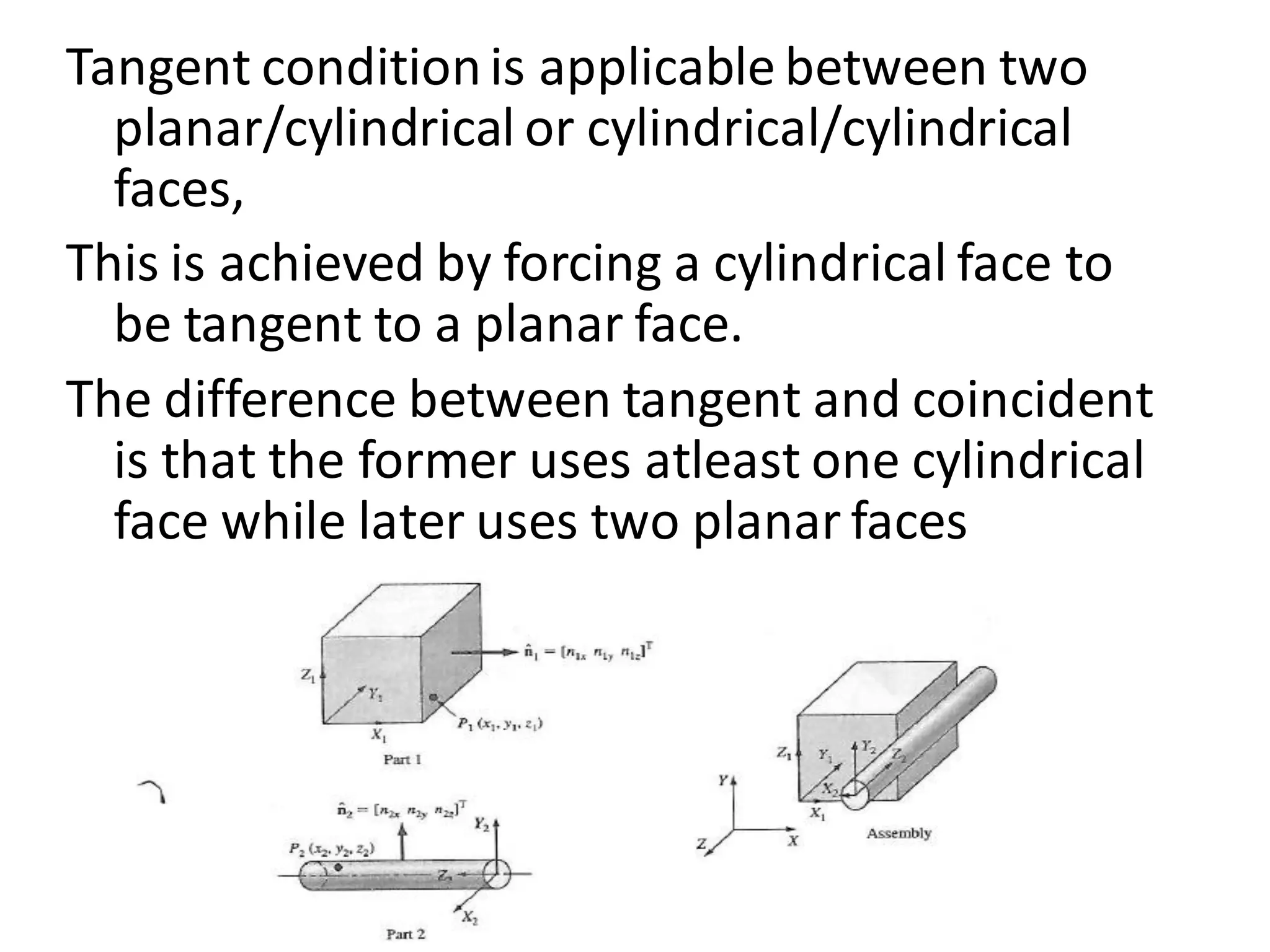

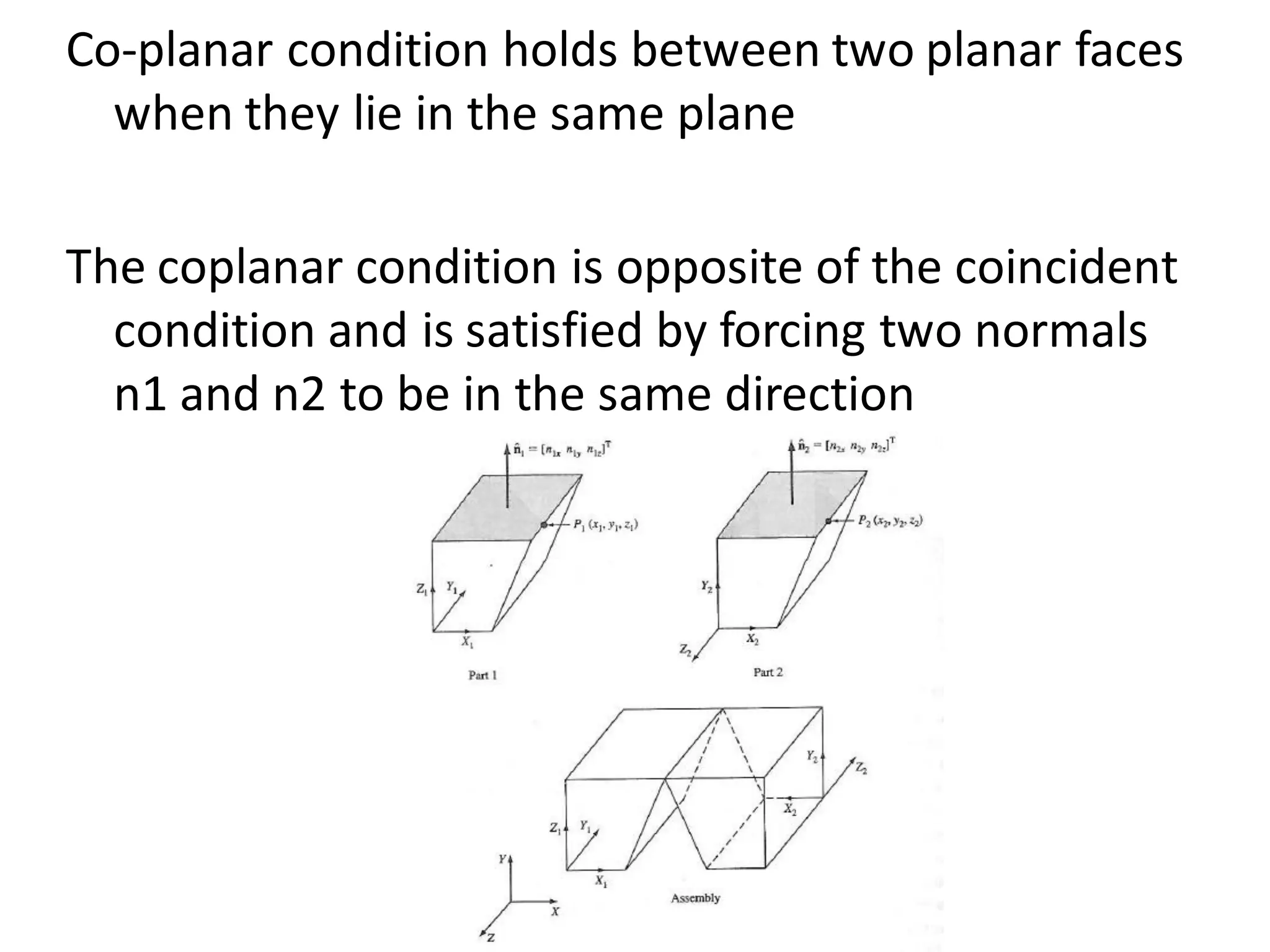

- Common mating conditions used to define spatial relationships between parts like coincident, concentric, coplanar, and their mathematical definitions.

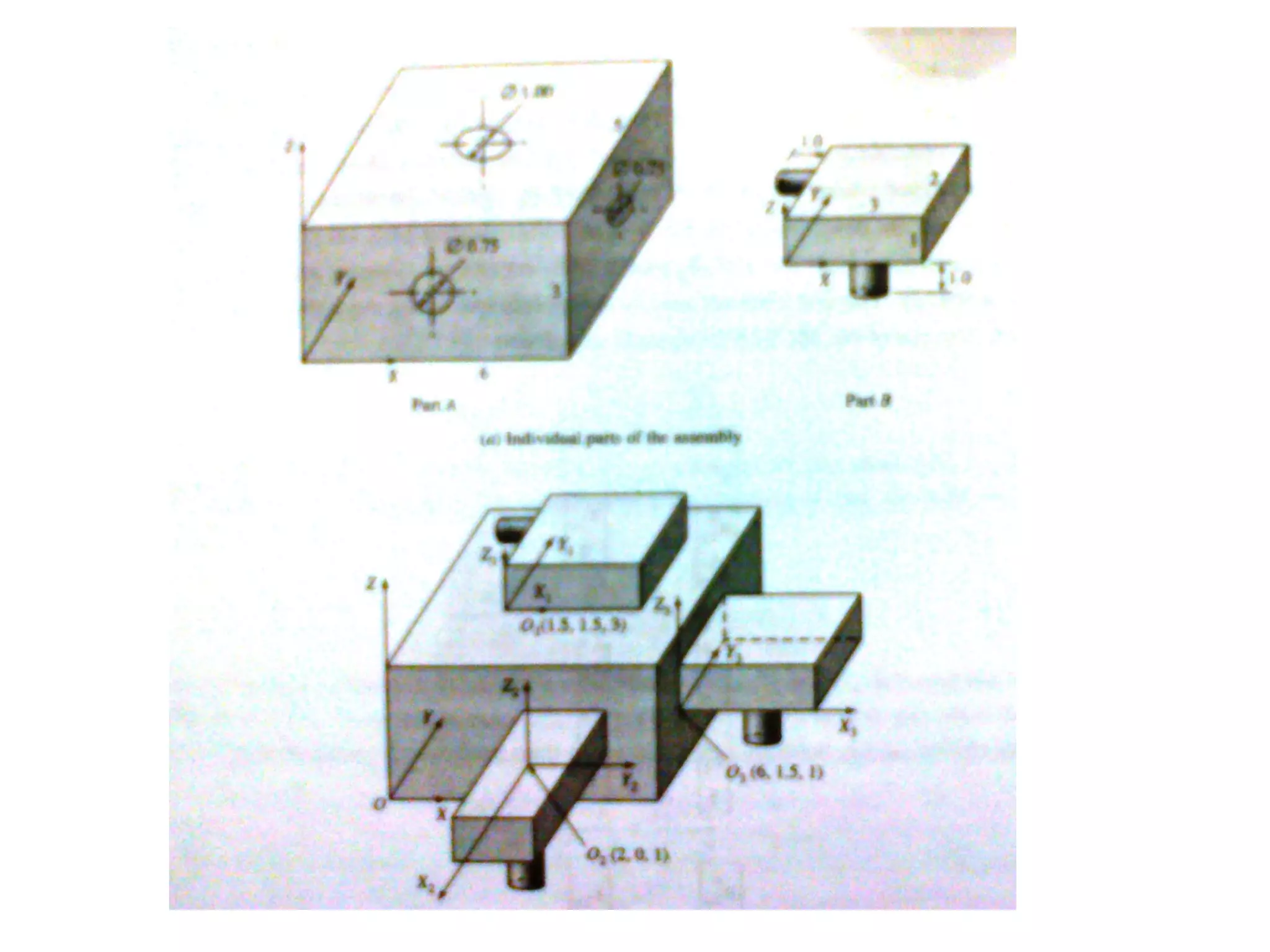

- Positioning and orienting parts in an assembly using transformation matrices and the world coordinate system method.

![Top down assembly approach

- Bottom up approach appeals to small assemblies consisting for

eg., hundred or maybe a thousand components

- Top down is suitable for large assemblies consisting of tens of

thousands of parts and sub assemblies

- Its an effective tool and a organised approach to manage the

design of large assemblies

- It allows a project leader to break up product specifications, assign work teams and

enforce downstream design changes at a high level

- It helps foster a systemsengineering approach to product design

- The assembly layout communicates design criteria to subsystem developers including

suppliers. The design control allows distributed design teams to work concurrently with a

common product framework

- It allows detail design to begin while the assembly layout is finalised

- This approach lends itself to conceptual design phase. Captures the design intent of a

product in the early design phases [doesn’t need to worry about detailed design]

- Allows designers to validate design concepts before implementing them, what if analysis

could be done](https://image.slidesharecdn.com/assemblymodelling-230309054901-06426287/75/assembly-modelling-pdf-22-2048.jpg)