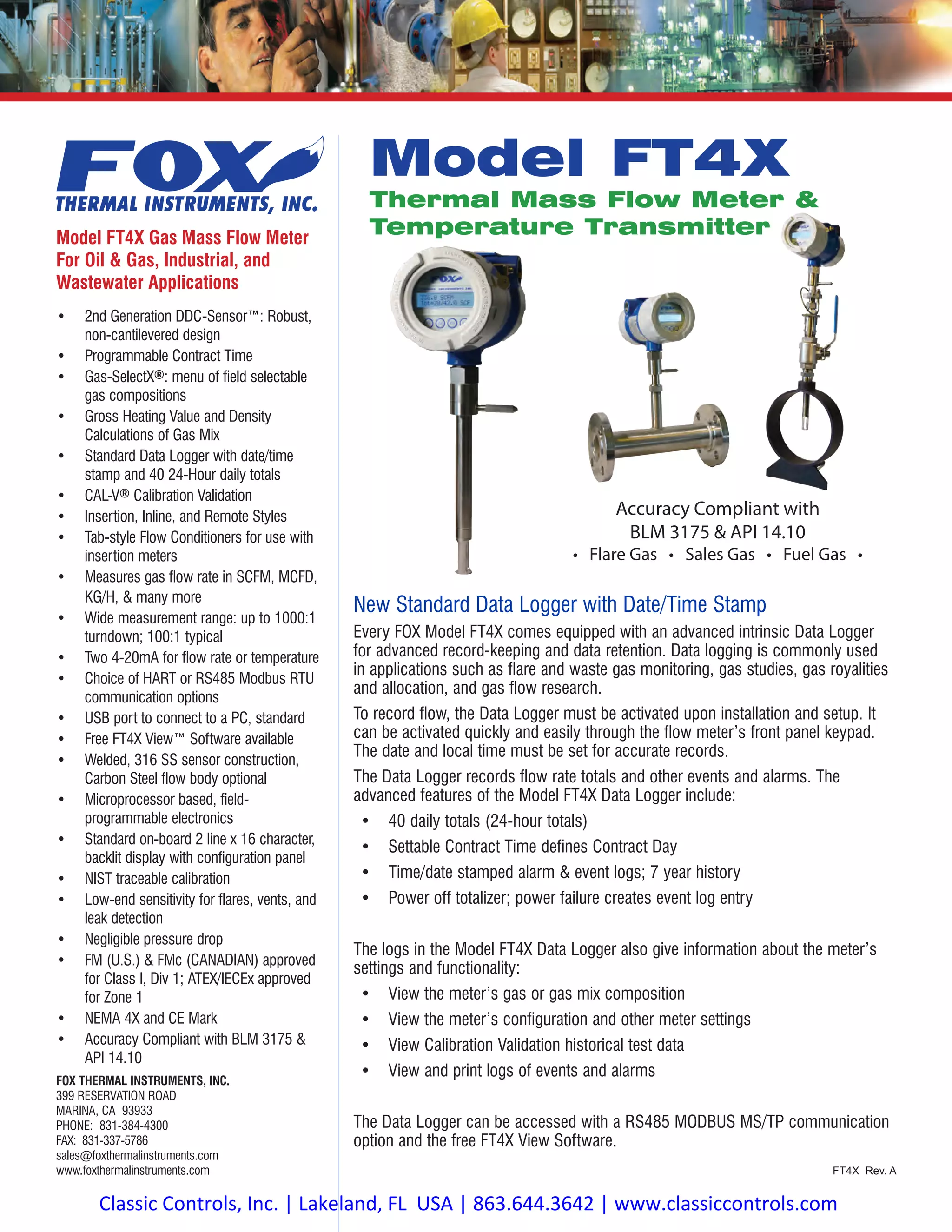

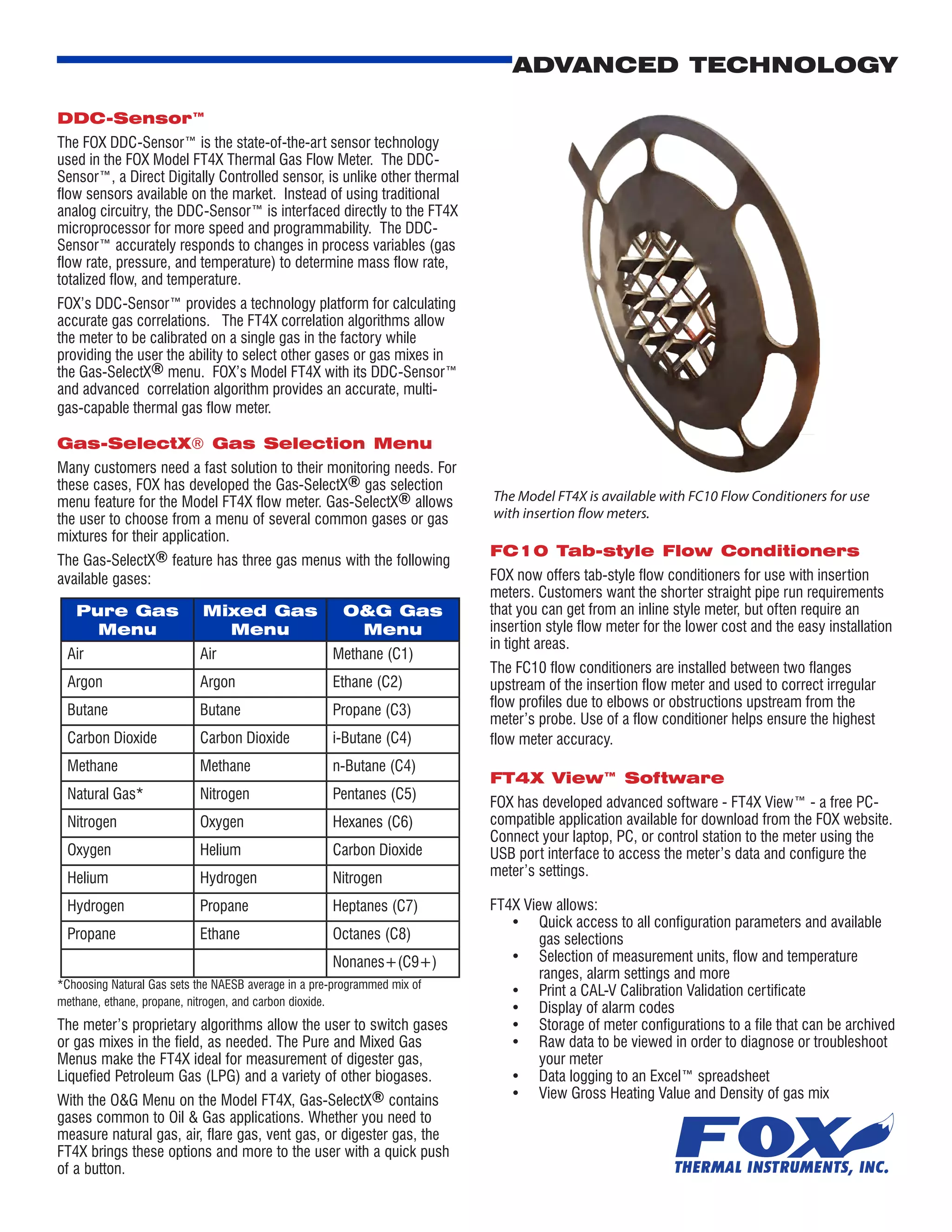

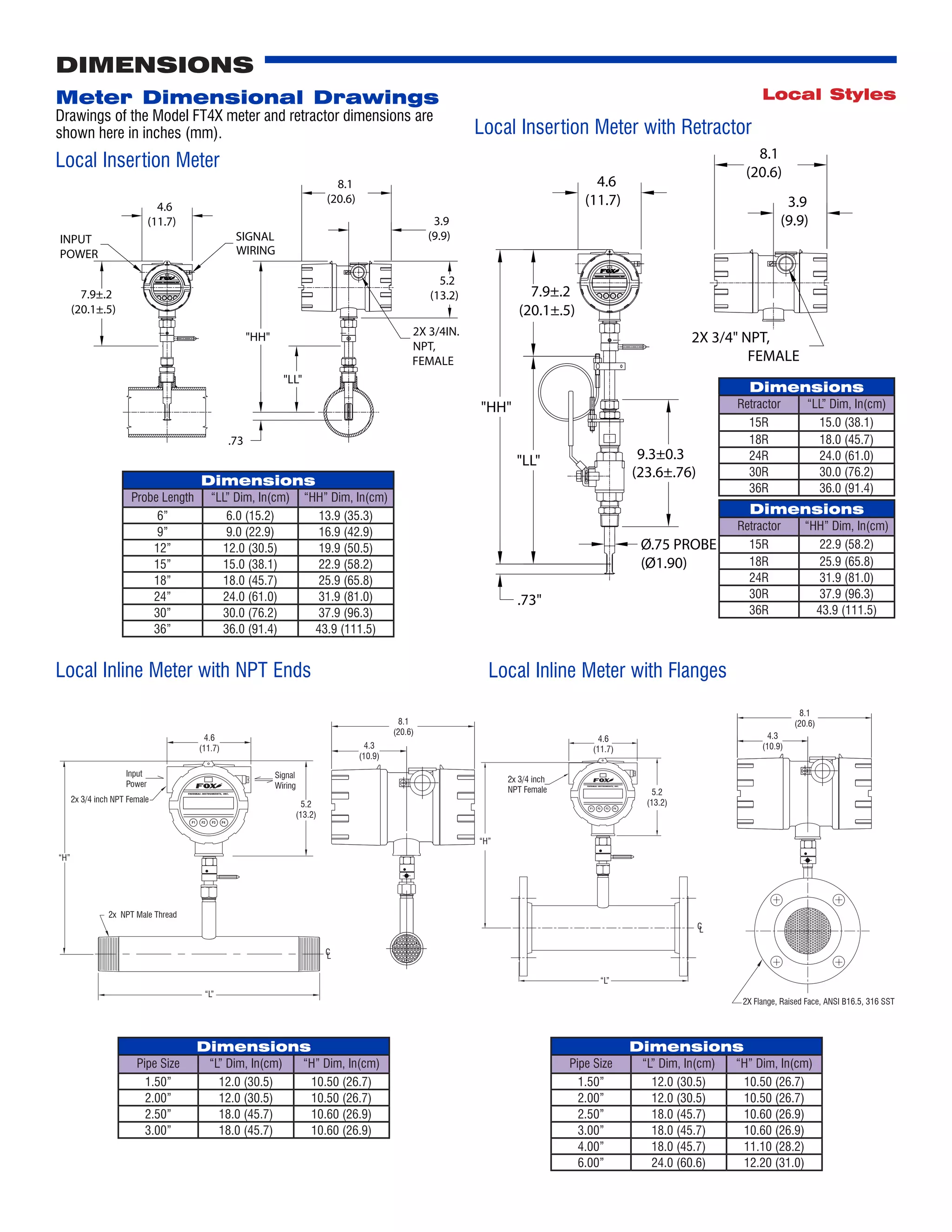

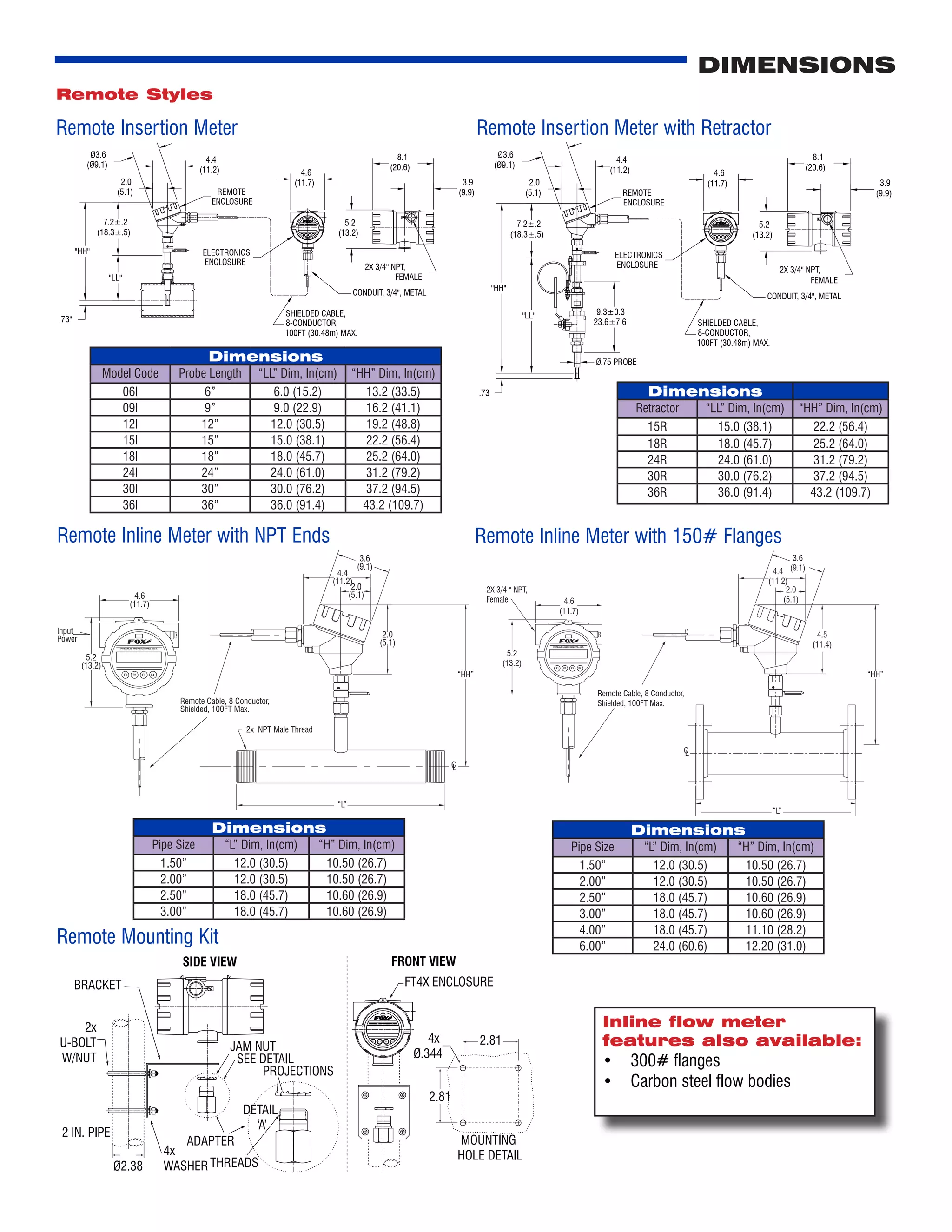

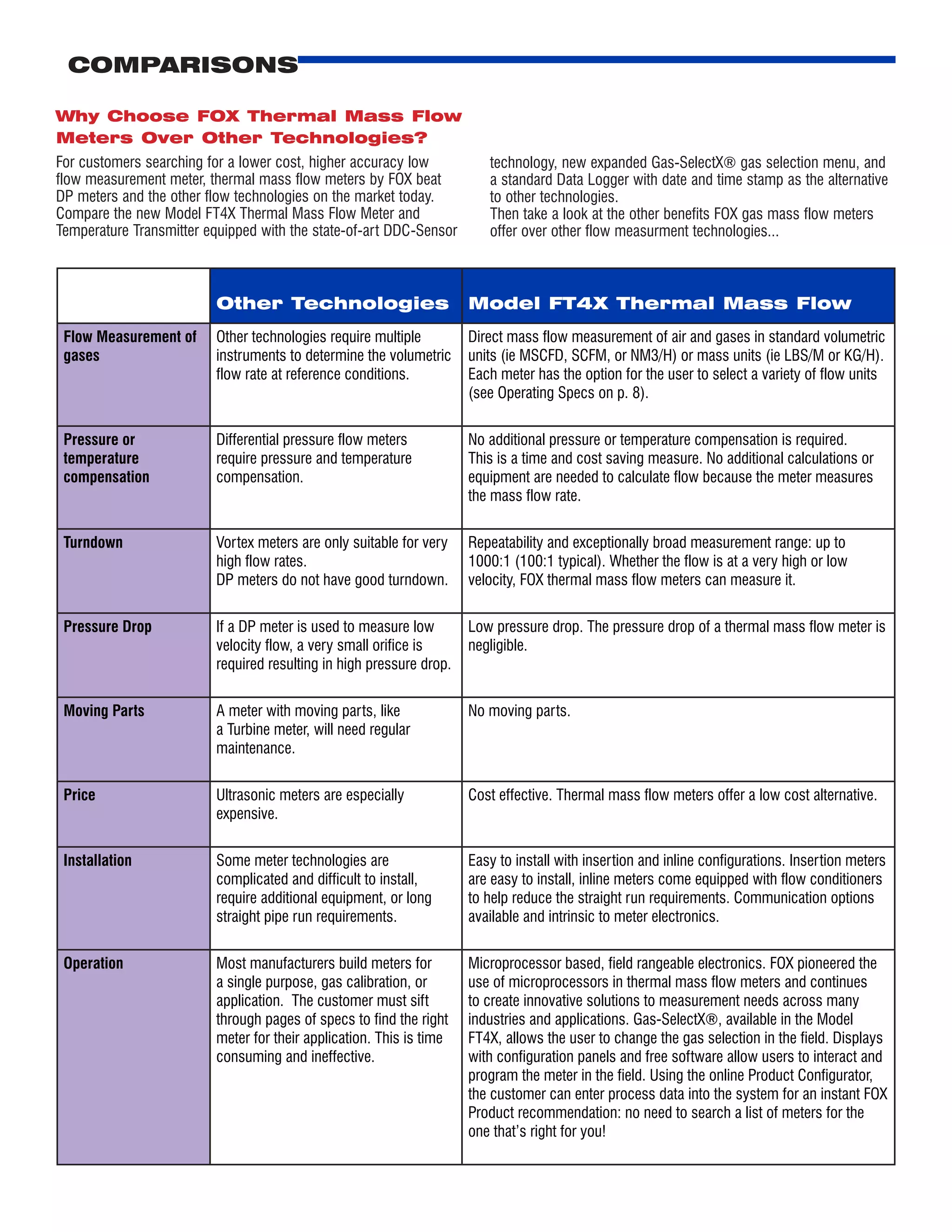

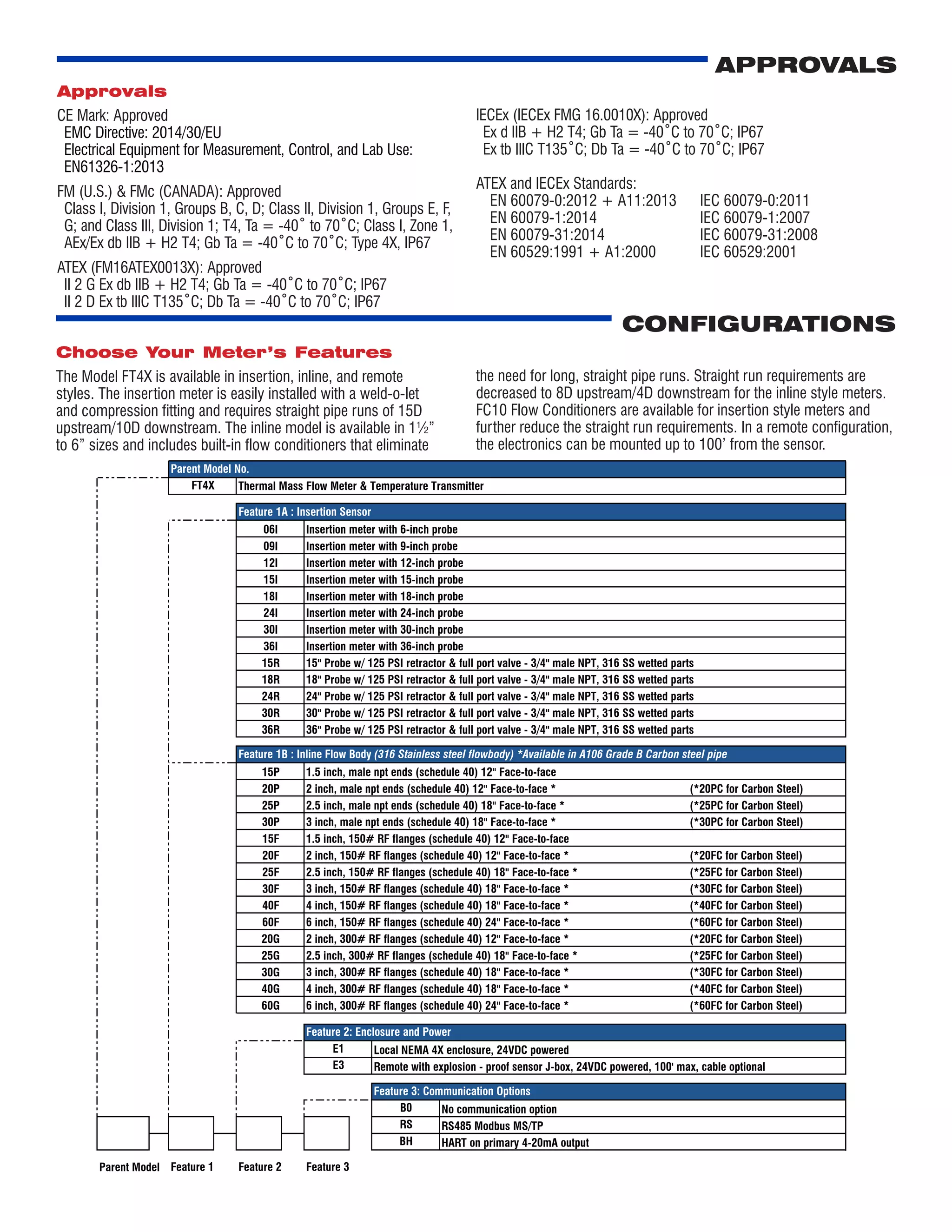

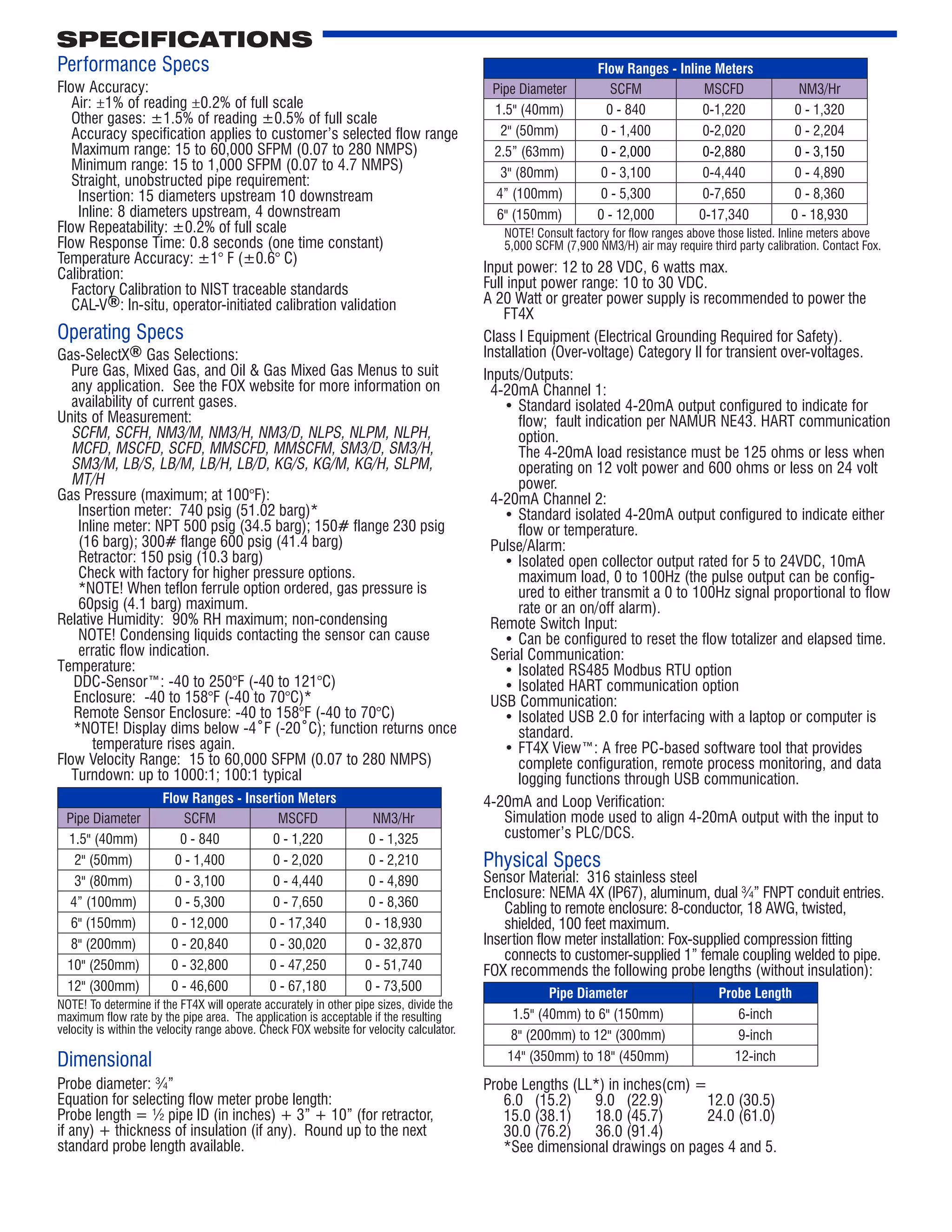

The document introduces the Fox Model FT4X thermal mass flow meter, highlighting its robust design, advanced data logging features, and multi-gas capability. It supports flexible gas flow measurement applications in oil and gas, industrial, and wastewater contexts, with options for various gas compositions and communication protocols. Key features include a digital sensor, NIST traceable calibration, and comprehensive monitoring tools to ensure accurate gas flow measurements.