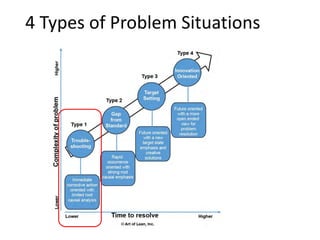

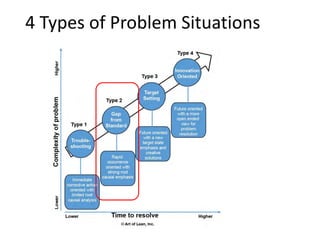

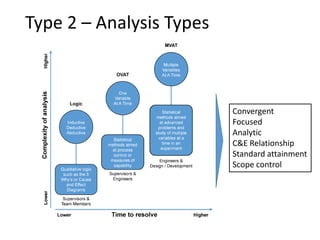

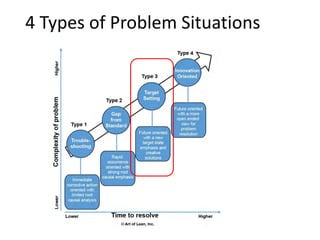

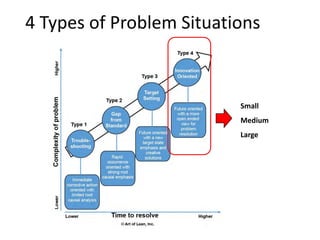

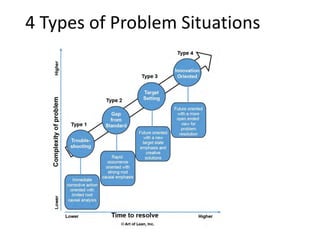

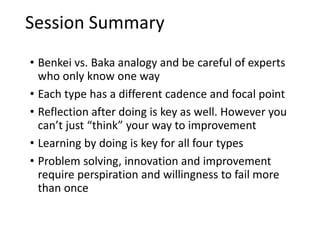

This document outlines 4 types of problem situations:

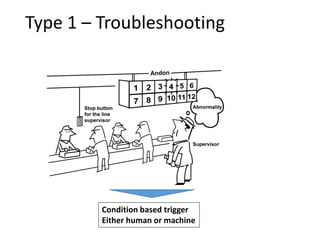

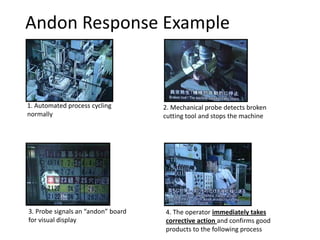

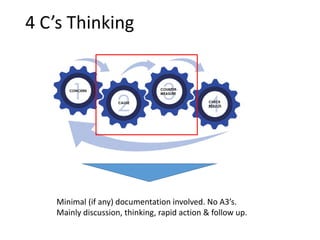

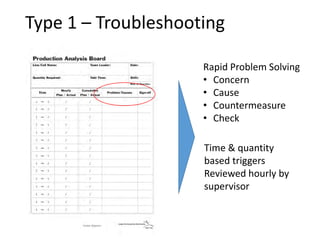

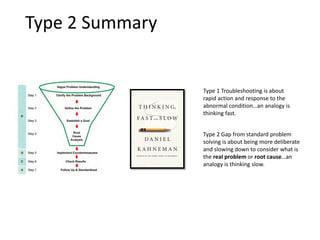

1) Type 1 involves troubleshooting rapid issues with minimal documentation.

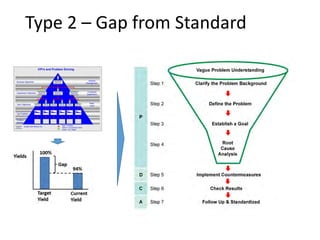

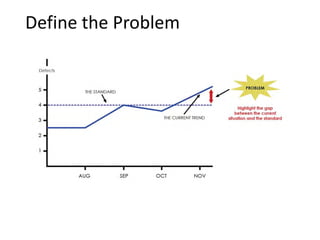

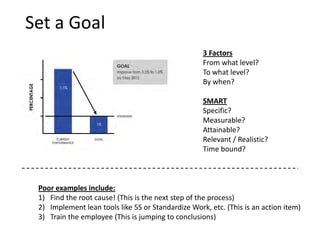

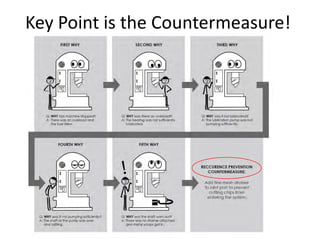

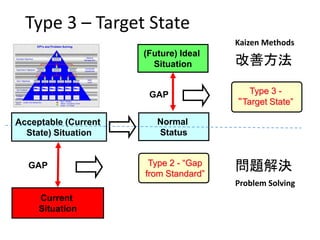

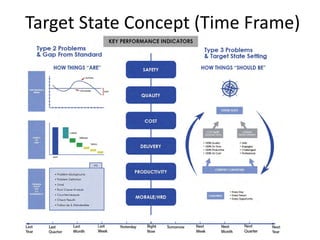

2) Type 2 involves identifying gaps from standards by slowing down to find root causes.

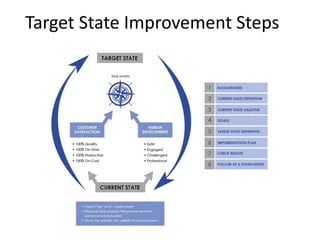

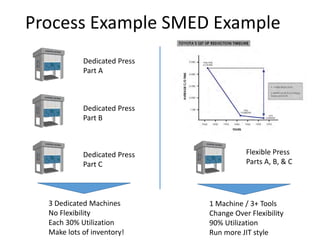

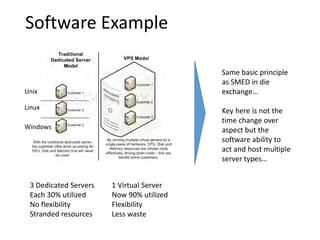

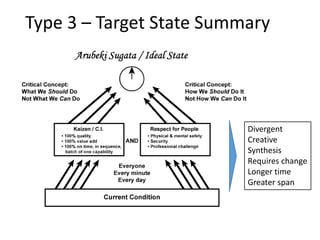

3) Type 3 focuses on defining a target state with longer term, creative solutions like new processes.

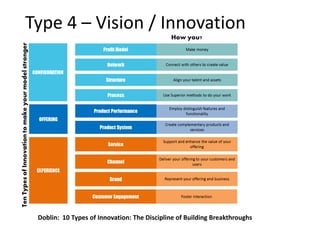

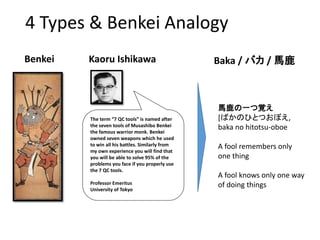

4) Type 4 centers around innovation and vision setting for the future. The summary emphasizes practicing all 4 types and learning through doing, rather than only knowing one approach.