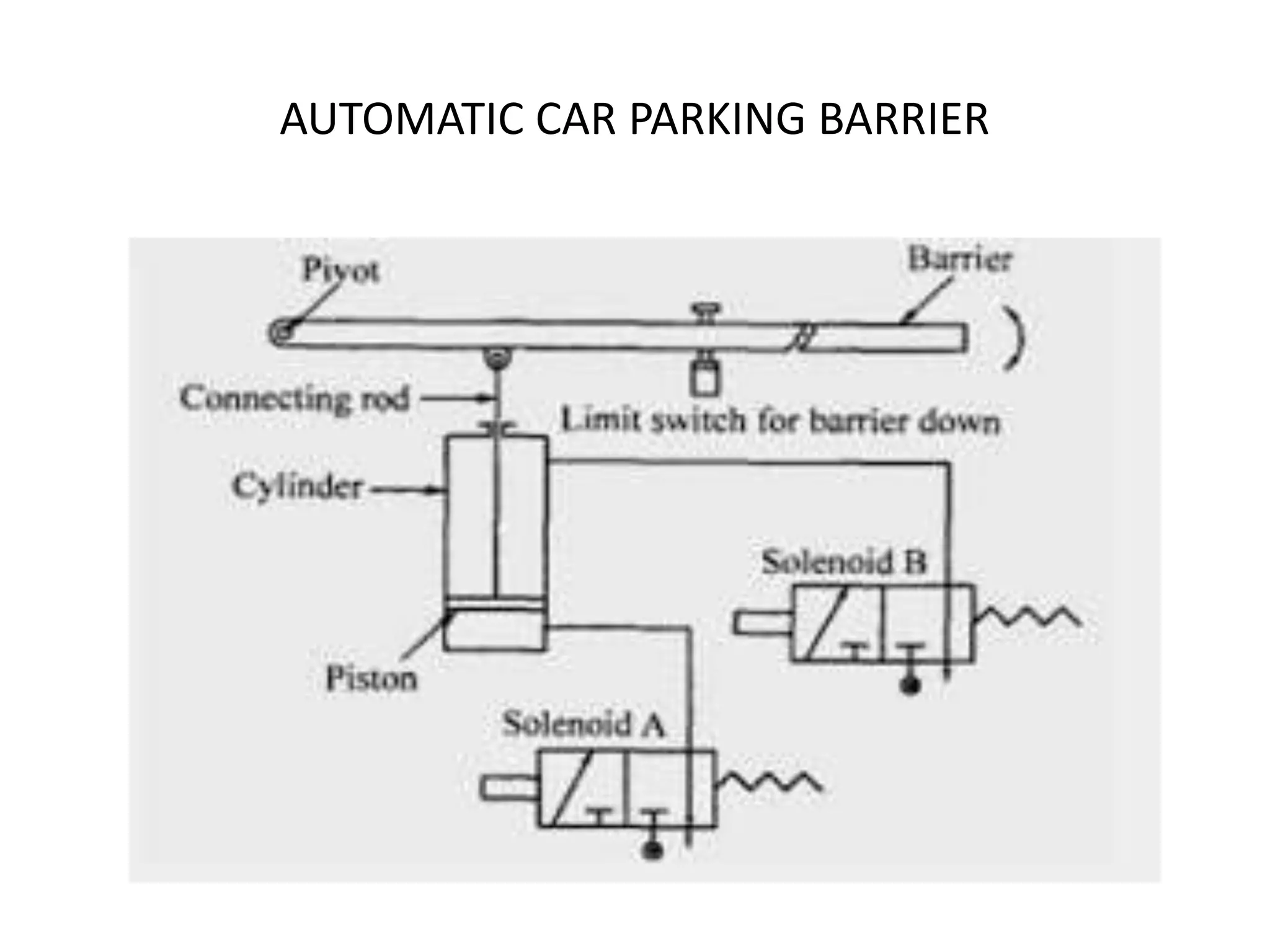

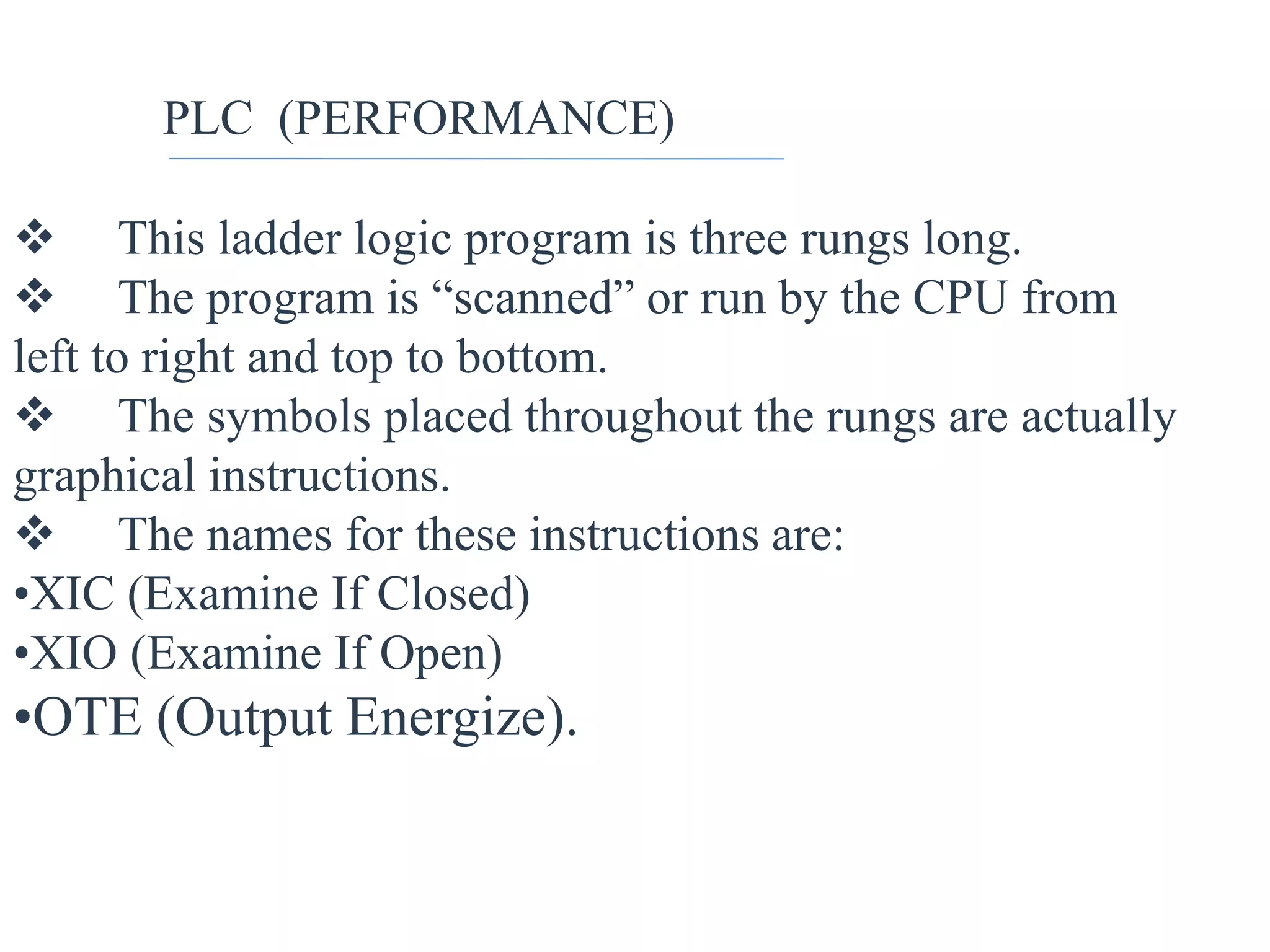

This document describes an automatic car parking barrier system using a programmable logic controller (PLC). It consists of barriers that pivot up and down to allow cars to enter and exit the parking area. Solenoid valves and a piston cylinder arrangement are used to control the movement of the barriers. When a coin is inserted, solenoid A raises the barrier to allow entry. Sensors detect when a car is in front of the exit barrier and solenoid B then lowers it to allow exit. The system uses ladder logic programming in the PLC to control the operation of the barriers and coin counting system.