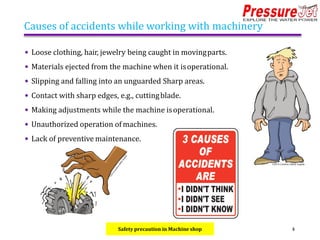

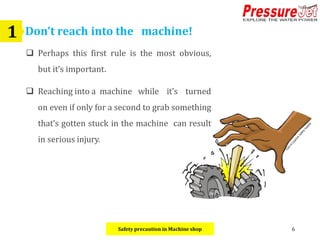

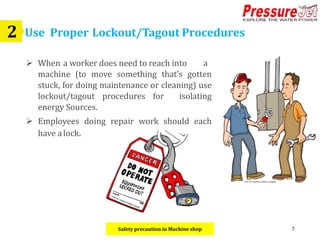

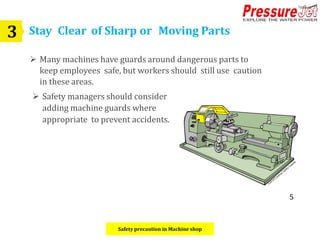

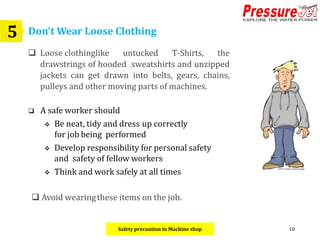

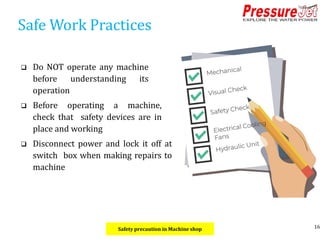

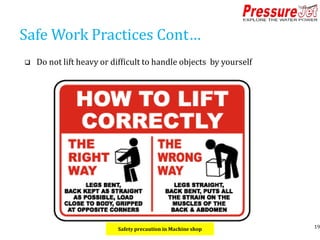

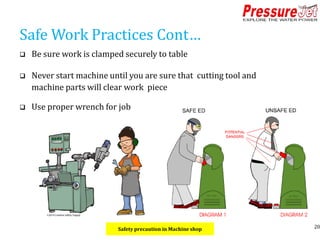

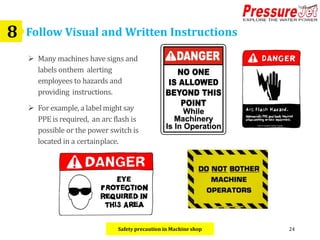

The document outlines crucial safety precautions for working in a machine shop to prevent serious injuries from unguarded moving parts and improper practices. Key measures include using lockout/tagout procedures, wearing appropriate safety gear, and maintaining a clean workspace, along with clear communication among workers. It emphasizes the importance of understanding machine operations and adhering to safety guidelines to ensure a safe working environment.