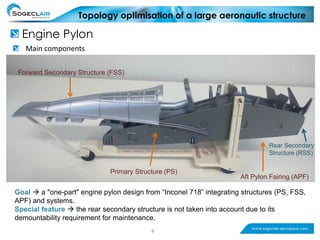

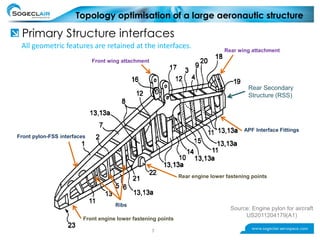

1) The document discusses using topology optimization to design an improved engine pylon concept for an aircraft. It aims to reduce mass, part count, and assembly time compared to the current design.

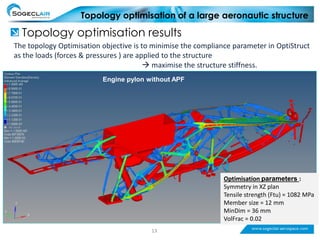

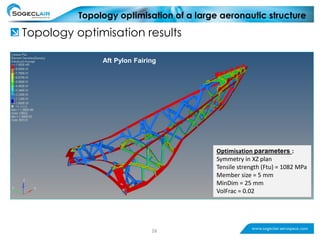

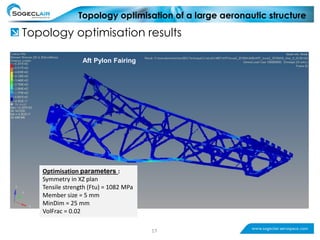

2) Topology optimization was performed on the engine pylon and aft pylon fairing using Altair OptiStruct to minimize compliance. This provided optimized structural designs with up to 200kg mass savings per plane.

3) Preliminary analysis shows the optimized design could reduce the part count from over 650 parts to just 14 parts, and assembly time from over 2600 fixes to around 350 fixes.